CW Blog

Top 10 CompositesWorld articles of 2023

Through a variety of editorial content, CW explored the trends and topics that are rapidly flourishing in the industry. Based on Google Analytics, these top 10 articles were considered the most popular.

Read MoreLooking back at 2023 to look forward

As 2024 begins, we look at trending topics and our most-read stories in 2023, plus highlight new content for the new year.

Read MoreInnovation in ultrasonic inspection and nondestructive testing

With increasingly complex structural components working their way into aerospace programs, the need for versatility in inspection and testing capabilities is growing.

Read MoreTop 10 CompositesWorld products of 2023

A variety of novel materials, processes targeting the composites industry’s light weight, sustainability and more rapid production efforts made CW’s top 10 most popular product pieces of 2023 based on Google Analytics.

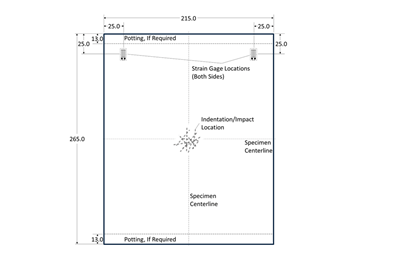

Read MoreDamage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

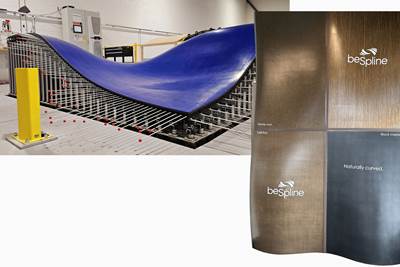

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreTop 10 CompositesWorld news items of 2023

Explore 2023’s standout moments in the composites industry with CW's compilation of the top 10 news articles, determined by Google Analytics.

Read MoreManufacturing tech for scalable Type V hydrogen tank fabrication, CFRP lifecycle management

Cygnet Texkimp’s Multi Roll Stack and composite recycling technology catalyze ASCEND program’s mission to optimize aerospace, automotive hydrogen storage and CFRP sustainability.

Read MoreSolar-powered photonic cooling enables energy-saving coating

Passive cooling technology can reduce interior temperatures 5-13°C, offering weight, cost and CO2 benefits for cars, construction, aircraft and more.

Read MoreMulti-material, self-sensing, 3D-printed scoliosis braces

Startup Fited and Brightlands Materials Center have developed a lighter weight, thinner CFRP corrective brace, including pressure sensors made from continuous carbon fibers.

WatchFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

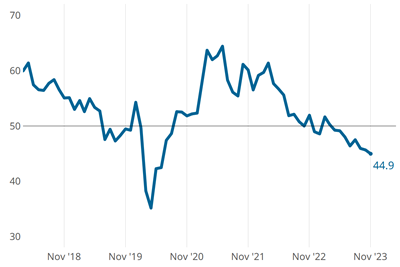

Read MoreComposites industry heads into slightly accelerated contraction in November

The GBI: Composites Fabricating in November continued its general slow-going path of contraction that began in April 2023.

Read More