CW Blog

Creating a culture of excellence in aerocomposites

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreFastener selection for composite materials

How to navigate terminology, materials and functionality in choosing the right fastener for components or assemblies involving composite materials.

Read MoreScaling up sustainable solutions for fiber-reinforced composites

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

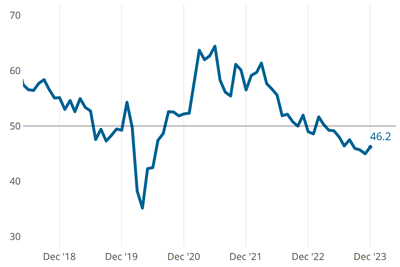

Read MoreComposites industry gained back some ground in December

The GBI: Composites Fabricating contracted a little more slowly in December, landing between August and September 2023 values.

Read MoreJEC World 2024 preview

The world’s largest composites industry trade event returns to Paris, France, March 5-7, 2024, featuring exhibits, awards, conference programming and more.

WatchComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

WatchFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

WatchComposites end markets: Sports and recreation (2024)

Light weight and high performance continue to make composites popular in the elite sporting good market. Sustainability in both materials and recycling solutions are a key innovation area.

WatchTop 10 CompositesWorld articles of 2023

Through a variety of editorial content, CW explored the trends and topics that are rapidly flourishing in the industry. Based on Google Analytics, these top 10 articles were considered the most popular.

Read MoreLooking back at 2023 to look forward

As 2024 begins, we look at trending topics and our most-read stories in 2023, plus highlight new content for the new year.

Read MoreTop 10 CompositesWorld products of 2023

A variety of novel materials, processes targeting the composites industry’s light weight, sustainability and more rapid production efforts made CW’s top 10 most popular product pieces of 2023 based on Google Analytics.

Read More