Whitepapers

Jetcam addresses the economic importance of efficient material nesting

Jetcam’s latest white paper explores the critical aspects of nesting in composites manufacturing, and strategies to balance material efficiency and kitting speed.

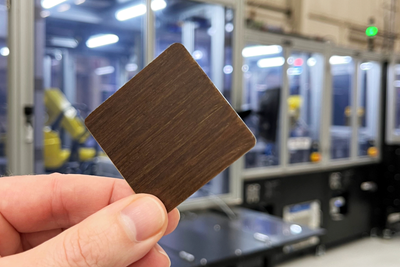

Read MoreArris Composites demonstrates advantages of natural fibers applied with Additive Molding

Arris presents mechanical testing results of an Arris-designed natural fiber thermoplastic composite in comparison to similarly produced glass and carbon fiber-based materials.

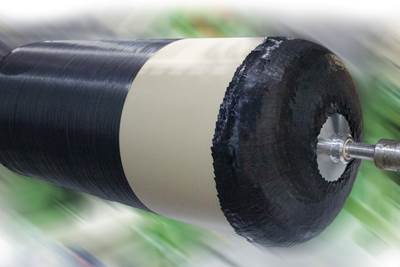

Read MoreCevotec white paper presents novel approach for H2 tank production

Cevotec, a tank manufacturer, Roth Composite Machinery and Cikoni, have undertaken a comprehensive project to explore and demonstrate the impact of dome reinforcements using FPP technology for composite tanks.

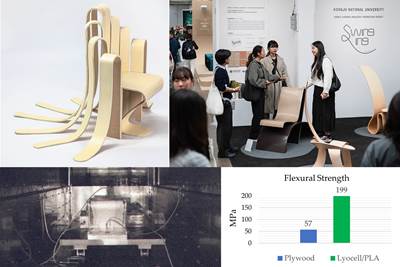

Read MoreKCARBON and KIST develop lyocell/PLA/wood biocomposites

Initial demonstration in furniture shows properties two to nine times higher than plywood, OOA molding for uniquely shaped components.

Read MoreExel Composites releases guide for design considerations in composite tubes

The composite tubes white paper explores some of the considerations for specifying composite tubes, such as mechanical properties, maintenance requirements and more.

Read MoreUAMMI white paper addresses composites recycling in Utah

Foundational research discusses the current carbon fiber recycling landscape in Utah, and evaluates potential strategies and policies that could enhance this sustainable practice in the region.

Read MoreExel Composites releases FST requirements guide for composites

In its latest white paper, Exel navigates the fire, smoke and toxicity (FST) considerations and complexities that can influence composites design.

Read MoreEvonik study researches best resins for surface quality and shrinkage control

New white paper authored by Eike Langkabel, Sebastian de Nardo, and Jens Bockhoff, examines the best resin formulations for composites used in automotive part production, both structural parts and body panels.

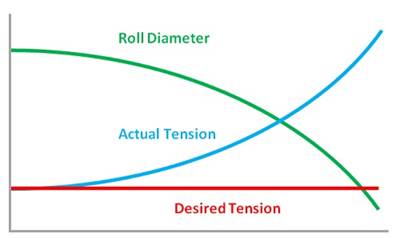

Read MoreThe Montalvo Corp. white paper: Tension Control

Tension control plays a vital role in composites manufacturing in order to achieve automated processing, continuous processing, reduced scrap, increased product quality, and more, says a new white paper released by The Montalvo Corp.

Read More