CW Blog

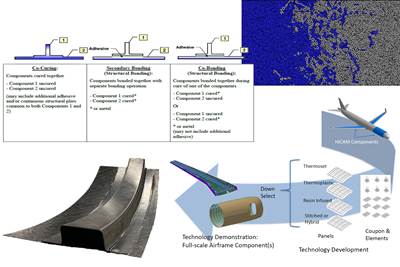

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

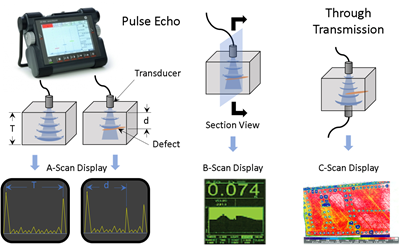

Read MoreNondestructive inspection methods available to composites manufacturers

An overview of composite laminate inspection techniques ranging from manual testing methods to more advanced, noncontact options.

Read MoreThermoplastic composite, tube-shaped preforms for large-volume manufacturing

Starting with the sporting goods and bicycle market, French startup 3DiTex targets its continuous preforming system for thermoformable, thermoplastic composite tubes in complex geometries.

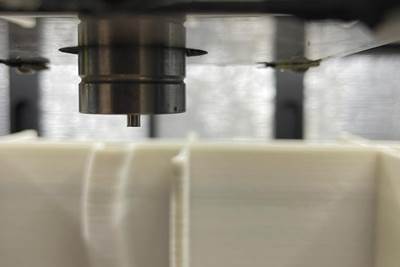

WatchIncreased molding productivity via additive manufacturing

Companies in multiple segments turn to 3D printing for end-of-arm tools, fixtures for increased safety and functionality, lower cost and faster turnaround times.

Read MoreBio-based SiC ceramics from wood polymer composites

Austrian research institute Wood K plus makes 95% silicon carbide ceramics more sustainable (>85% bio/recycled content), enables 3D shapes via extrusion, injection molding and 3D printing.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

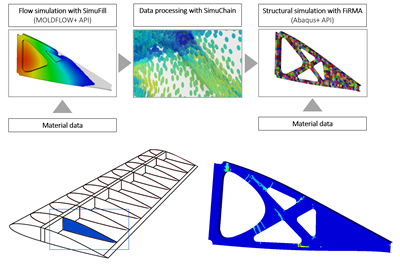

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

WatchEpisode 43: Emphasizing the recycling of wind blades

CW Talks discusses Ford Motor Company’s involvement with the EMPHASIZING project, a UK consortium working to develop a material from recycled glass fiber with mechanical properties superior to virgin glass.

ListenComposites industry saw stabilized contraction in October

The GBI: Composites Fabricating index has contracted for the seventh month in a row, with one notable change in component activity.

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

WatchCAMX 2023 Show Daily: Thursday, Nov. 2

CW is reporting live on the CAMX show floor in Atlanta, Georgia. Download today’s Show Daily covering interesting exhibitors and technologies, the committee members and volunteers that make the show possible, “Good Day, CAMX” results and a look back at show floor activities.

Read MoreCAMX 2023 Show Daily: Wednesday, Nov. 1

CW is reporting live on the CAMX show floor in Atlanta, Georgia. Download today’s Show Daily covering key keynote takeaways, CAMX Award and ACE winners, CAMX’s evolution over the years, a book signing at the SAMPE booth, breakfast on the last day and much more!

Read More