Injection/Overmolding

Injection or overmolding techniques in composites involve the process of injecting or molding a composite material over a pre-existing structure or component, enhancing its functionalities or adding protective layers. This method allows for the combination of different materials, such as polymers or composite resins, to create a cohesive and integrated final product. It's commonly used to reinforce or encapsulate parts, providing improved strength, durability, and resistance to environmental factors.

Latest Injection/Overmolding Articles

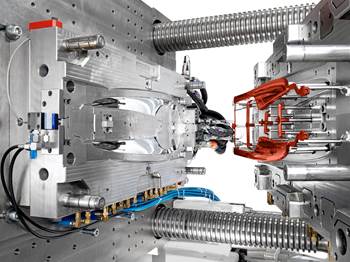

VIEW ALLFiber Dynamics invests in GX 1100 DCIM from KraussMaffei

Direct compounding injection molding (DCIM) enables the composites company to develop, test and protect its own recipe formulations, while increasing cycle times by eight times and reducing energy consumption.

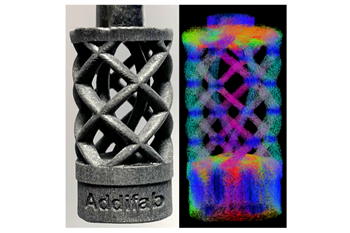

Read MoreXnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

Read MoreKraussMaffei and partners develop sustainable, safe and stylish children’s bike

The Lion Bike is a German-made, injection molded bicycle with 40% recycled carbon fibers with zero scrap and enabling 67% lower CO2 emissions during production.

Read MoreMachinery, systems manufacturer highlights 3D printing, thermoplastics processing

CAMX 2023: KraussMaffei is featuring a variety of technologies, including Fiberform, ColorForm, RTM, extruder-based 3D printing and more.

Read MoreINN-PAEK project succeeds in 100% recyclable turbine

European project replaces complex-shaped metal structure in aircraft cooling system with injection molded thermoplastic composite material for improved sustainability.

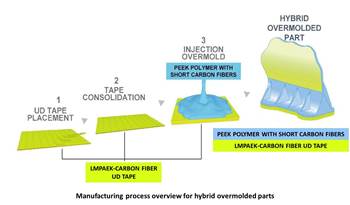

Read MoreTool Gauge, Victrex partner to develop co-molded composite aircraft parts

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

Read MoreKnowledge Centers

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORELatest Injection/Overmolding News And Updates

Windform XT 2.0 IMG brings sustainability to injection molding

Carbon fiber-reinforced PA12 thermoplastic launched by CRP Technology is a 100% recycled high-performance material derived from the Top-Line range for 3D printing.

Read MoreBlueHalo launches next generation of Intense Eye UAS

Unmanned aerial system (UAS) from BlueHalo featuring an HX5 injection-molded chassis from Alpine Advanced Materials is said to be lighter, stronger and more efficient than aerospace-grade aluminum.

Read MoreGerman consortium develops biopolymer-based Cellun composite

German Institutes of Textile and Fiber Research (DITF) and partners present a conventional composite material alternative using cellulose that can be processed using industrial processing methods.

Read MoreINN-PAEK project to develop 100% recyclable, lightweight thermoplastic flange wheels for future aircraft

The AITIIP Technology Center leads this research with partner Liebherr Group to develop a technology by June 2023 that contributes to more sustainable, eco-friendly production systems.

Read MoreComposite truck component carrier from Lanxess wins GKV/TecPart Innovation Award

Injection-molded glass fiber-reinforced PA6 component is jointly developed with system supplier and truck manufacturer for 35% less weight, replaces DLFT-based design.

Read MoreCovestro, Arcesso Dynamics launch solid-surface manufacturing solution Arfinio

First use of reaction injection molding (RIM) on aliphatic polyurethanes enables complex, lightweight and seamless designs and new property combinations.

Read MoreFeatured Posts

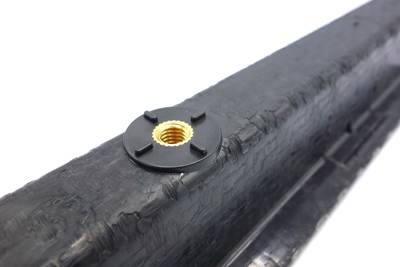

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreSeat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

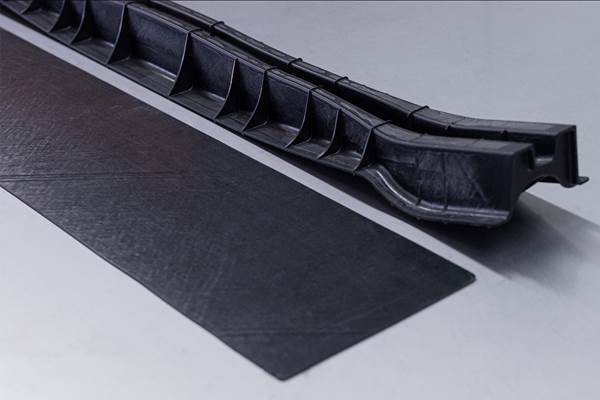

Read MoreThermoset-thermoplastic joining, natural fibers enable sustainability-focused brake cover

Award-winning motorcycle brake disc cover showcases potential for KTM Technologies’ Conexus joining technology and flax fiber composites.

Watch

.jpg;maxWidth=300;quality=90)