Composites Use in Wind/Energy Markets

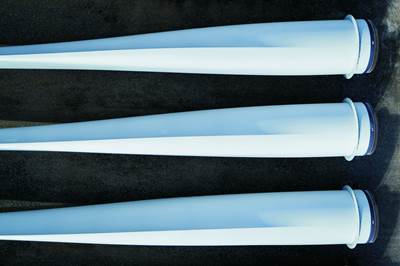

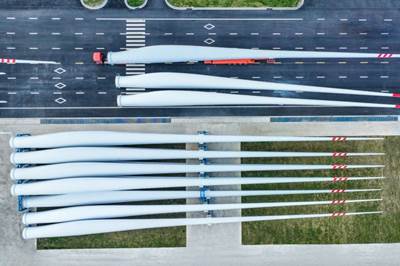

The wind energy market has long been considered the world’s largest market, by volume, for glass fiber-reinforced polymer (GFRP) composites — and increasingly, carbon fiber composites — as larger turbines and longer wind blades are developed, requiring higher performance, lighter weight materials. The outer skins of wind and tidal turbine blades generally comprise infused, GFRP laminates sandwiching foam core. Inside the blade, rib-like shear webs bonded to spar caps reinforce the structure. Spar caps are often made from GFRP or, as blade lengths lengthen, pultruded carbon fiber for additional strength.

Latest Wind/Energy Articles

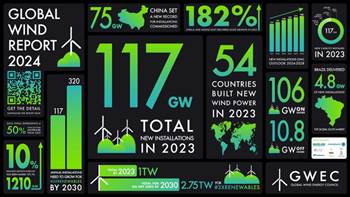

VIEW ALLGWEC 2024 report highlights positive momentum in wind installation

Global Wind Report describes a record year for wind energy in 2023, but highlights the need for policy-driven action to meet COP28 and 1.5°C pathway targets.

Read MoreNoble Gas awarded $500K for conformable, compressed gas storage tanks

DOE MAKE IT prize supports U.S.-based manufacturing of clean energy technology components for a diverse range of market applications.

Read MoreKineco Exel Composites India to supply carbon fiber planks for wind

Multi-year agreement between the joint venture and a South Asian wind turbine manufacturer contributes to composite spar cap development.

Read MoreAcciona to build wind blade recycling plant in Spain by 2025

Waste2Fiber facility will use a proprietary thermal method to separate wind blade materials for reuse and will have a processing capacity of 6,000 tons of material/year.

Read MoreOcean Winds takes full ownership of SouthCoast Wind project

Madrid-based international company is focused on the joint procurement process for offshore wind in Connecticut, Rhode Island and Massachusetts.

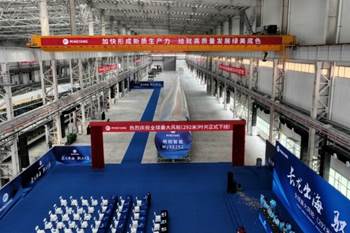

Read MoreHengshen carbon fiber contributes to 143-meter-long MingYang wind blade

First MySE292 offshore wind blade from MingYang Group successfully rolled off the production line in February.

Read MoreKnowledge Centers

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORELatest Wind/Energy News And Updates

UMaine researchers aim to recycle wind turbine blades as 3D printing material

With a DOE grant in hand, UMaine’s ASCC seeks to develop an approach to recycle shredded wind turbine blade material as a cost-effective reinforcement and filler for large-scale 3D printing.

Read MoreSwancor, Siemens Gamesa solidify recyclable wind blade partnership

Swancor will supply all recyclable resin to Siemens by 2026, contributing to RecylableBlade efforts.

Read MoreR&D projects, additively functionalized part demonstrate composites innovation

JEC World 2024: The DLR is presenting the EmpowerAX multi-curved shell demo part as a JEC Innovation Award winning innovation, in addition to results from other projects involving hydrogen tanks, wind and more.

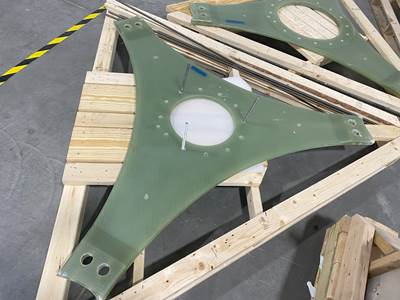

WatchComposites expertise targets wind turbine nacelles

JEC World 2024: BlueWind is exhibiting at JEC World for the first time at the Brazil Pavilion, highlighting a novel nacelle technology.

Read MoreGurit supports composites-focused wind projects, ferry development

Gurit announces an EcoVadis Gold rating, a collaboration on Hong Kong high-speed passenger ferries and work with the OptiCore Innovation Project.

Read MoreChina’s Sany Renewable rolls out 131-meter wind blade

Sany reports that it has adopted an optimized airfoil design with greater thickness and a blunt trailing edge to augment strength and stability.

Read MoreFeatured Posts

Repurposing wind blades as functional community art pieces

Ohio-based Canvus Inc. upcycles fiberglass wind blades, car tires and post-consumer plastics to create outdoor furniture that amplifies sustainability messages in community spaces.

WatchRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

WatchComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

WatchManufacturing tech for scalable Type V hydrogen tank fabrication, CFRP lifecycle management

Cygnet Texkimp’s Multi Roll Stack and composite recycling technology catalyze ASCEND program’s mission to optimize aerospace, automotive hydrogen storage and CFRP sustainability.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreCarbon Fiber 2023: See you there

CompositesWorld’s Carbon Fiber Conference, in its 26th year, will be held Nov. 28-30 in Salt Lake City, Utah, U.S. There are many good reasons to attend.

Read MoreFAQ: Wind/Energy

What are wind turbine blades made from?

- The outer skins of wind and tidal turbine blades generally comprise infused, GFRP laminates sandwiching foam core. Inside the blade, rib-like shear webs bonded to spar caps reinforce the structure. Spar caps are often made from GFRP or, as blade lengths lengthen, pultruded carbon fiber for additional strength.

- Source: Composites end markets: Renewable energy

What energy applications are composites used for?

In renewable energy, fiberglass composites are used, most prominently, to build wind turbine blades and nacelles. Carbon fiber composites are also used to build wind blade spar caps. Hydroelectric turbines, tidal energy turbines and other forms of renewable energy have also made use of composites.

In oil and gas, composites have long been used as a corrosion-resistant metal alternative for a number of applications, including components for protecting wellheads, manifolds and other equipment related to subsea processing, and offshore pipelines themselves.

What happens to wind blades at the end of their lifespan?

As wind energy ramps up, recycling of composite wind blades at their end of life (EOL) – as well as composites and plastics recycling in general – continues to be a topic of concern.

More than 80% of a wind turbine itself is typically metallic and recyclable, but the increasingly long, high-performance composite blades pose more of a challenge.

Efforts include:

-

-

- Near-term: Ramping up existing recycling methods like mechanical chopping up blades or repurposing entire blades for other uses

- Medium-term: Developing more efficient methods such as chemical recycling (solvolysis) for reclaiming the original fibers from EOL blades for reuse

- Long-term: Designing and manufacturing wind blades with sustainable/recyclable materials

-

.jpg;maxWidth=300;quality=90)