Composites Curing

Curing in composites refers to the process where the composite materials, typically comprised of a resin matrix and reinforcing fibers, undergo a chemical reaction or heat treatment to solidify and form the final desired shape and properties. This stage is critical as it transforms the raw materials into a durable and structurally sound composite. Curing methods vary based on the type of matrix—whether it's a thermosetting resin like epoxy or a thermoplastic resin. Heat, pressure, or a combination of both are often applied during curing to activate the chemical reactions that cross-link the molecules within the matrix, creating a robust bond between the fibers and the matrix.

Latest Curing Articles

VIEW ALLAbaris selects Premier ESR to optimize composite cure cycles

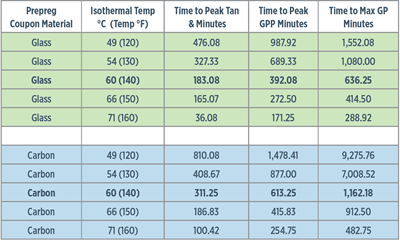

Encapsulated sample rheometer (ESR) by Alpha Technologies will be incorporated into Abaris’ service and consultation business to characterize a variety of composite material specimens.

Read MoreIntelligent autoclaves emphasize sustainability, efficiency

CAMX 2023: Olmar introduces its “intelligent” autoclave, a combination of the company’s Industry 4.0 technology and its 75 years experience in autoclave and oven manufacture.

Read MoreThermal processing workflow software effectively monitors composite processing equipment

CAMX 2023: State-of-the-art, user-friendly PCS 2.0 showcased by Walton Process Technologies is an Industry 4.0 process control software for autoclaves, presses and ovens.

Read MoreComposite curing ovens facilitate large composite parts manufacture

CAMX 2023: Wisconsin Oven’s composite curing ovens are designed to meet customers’ specific process requirements, featuring consistent temperature, quick heating and recovery rates, reduced maintenance and IoT capabilities.

Read MoreUV systems speed up curing process

CAMX 2023: IST Metz is exhibiting its portfolio of high-performance UV Arc and UV LED systems applicable for a range of composites processes.

Read MoreHigh-efficiency, low-energy industrial ovens, furnaces and washers

CAMX 2023: International Thermal Systems (ITS) offers a range of equipment that maximizes manufacturing efficiencies and minimizes energy consumption that include OOA composite curing ovens.

Read MoreKnowledge Centers

Review the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

LEARN MORELatest Curing News And Updates

SmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MoreAddyx carbon exoskeleton technology enables molded ribs inside hollow composite structures

Using a water-soluble mandrel, carbon exoskeleton opens paradigm for topology-optimized composites, cutting weight, manufacturing time and scrap rate.

WatchGMI Aero extends Anita EZ hot bonder thermocouple capabilities

Thirty-six thermocouples (T/Cs) are now available for flexible temperature monitoring/control during composite curing.

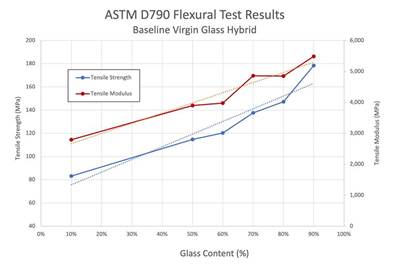

Read MorePilot program turns EOL wind blades to liners for pipe infrastructure

TPI Composites, Tex-Tech and Carbon Rivers partner to process wind blades, pyrolyze the material and use the recovered glass fibers to give new life to damaged existing pipelines.

Read MoreEUVAM project investigates energy-efficient UV process for composites curing

University of Stuttgart researchers intend to develop flexible, highly productive and digitally controllable manufacturing approach for small urban vehicle production.

Read MoreDLR completes MFFD upper shell skin layup

Eight-meter-long CFRTP fuselage skin was achieved via laser-heated in-situ consolidation, with stringers, frames and cleats to be welded.

Read MoreFeatured Posts

Real-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreFingerprinting liquids for composites

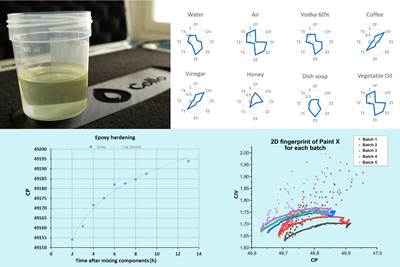

Collo uses electromagnetic sensors and edge analytics to optimize resin degassing, mixing, infusion, polymerization and cure as well as monitoring drift from benchmarked process parameters and enabling in-situ process control.

WatchPlant tour: Bucci Composites, Faenza, Italy

A stalwart in Italy’s “Motor Valley” opens its doors for a discussion and exploration of the company’s history in composites manufacturing for high-performance cars and other applications.

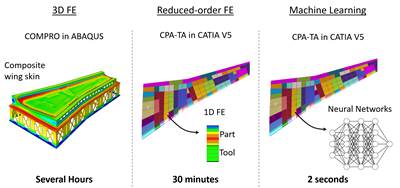

Read MoreUsing machine learning to accelerate composites processing simulation

A speed gain of 1,000 to 10,000 times greater than traditional FE models has been achieved using machine learning models, enabling near real-time simulation for large composite components.

Read More

.jpg;maxWidth=300;quality=90)