Axillium to support, manage U.K.’s ASCEND program

Innovation management partner Axillium explains its role in development of the Aerospace and Automotive Supply Chain Enabled Development (ASCEND) program launched in the U.K. in March 2021.

Will Searle, chairman of Axillium. Photo Credit: Axillium

GKN Aerospace (Solihull, U.K.) announced in March that it is leading a new U.K. industry consortium called ASCEND (Aerospace and Automotive Supply Chain Enabled Development) to develop and accelerate composite manufacturing and processing of composites technologies for the next generation of energy-efficient aircraft and future mobility.

The £39.6 million consortium is funded by a £20 million commitment from industry and a £19.6 million commitment from the UK Government via InnovateUK and the Aerospace Technology Institute (ATI). It will focus on greater adoption of composite technologies, the industrialization of new technologies through the acceleration of commercial aerospace production rates to meet future flexible high-volume requirements.

This includes the development of advanced material and automation equipment technologies across the U.K. supply chain to manufacture lightweight structures for the sustainable air mobility, aerospace and automotive industries.

Vital to the launch of ASCEND was Axillium, a U.K.-based firm that facilitates and manages research, innovation and investment strategies. Axillium, founded in 2007, is led by chairman Will Searle, who has experience with advanced materials and composite materials via work he did with Airbus on development of the A350. He says Axillium is positioned as an interface between government and private sector to help coordinate and facilitate funding and partners that are pursuing new technologies and R&D innovation designed drive change in the manufacturing sector.

Searle says ASCEND’s genesis began in late 2018 as Axillium began an effort to map U.K. technological and manufacturing capabilities against the demand for such capabilities. The 2019 report that came out of that effort was subsequently taken to GKN for evaluation. Searle says Axillium had worked with GKN in the past, thus the aerospace Tier 1 was a natural starting point. The report revealed a specific challenge: The commercial aerospace and emerging mobility sectors were in need of a level of high-rate, composite materials and manufacturing industrialization that does not yet exist in the U.K.

Searle says Axillium and GKN agreed to develop a multi-partner program — ASCEND — designed to convene materials and process subject matter experts who could meet the challenge. Axillium worked with GKN to source potential partner companies in this effort, and to identify potential government and industry sources to help fund the work. This led, in 2019, to a workshop that convened 45 potential partners; this number was subsequently whittled down to 16 and ASCEND was launched.

The program’s partners, in addition to GKN, are Assyst Bullmer (Wakefield), Cobham Mission Systems (Wimborne), Cygnet Texkimp (Northwich), FAR-UK Ltd. (West Bridgford), Hexcel Composites (Cambridge), Hive Composites (Leicestershire), LMAT, Loop Technology (Dorchester), McLaren Automotive (Woking), the National Composites Centre (NCC, Bristol), Rafinex (London), Sigmatex (Cheshire), Solvay Composite Materials, as well as Airborne (Lambourn) and Des Composites (Sheffield). ASCEND’s core group is composed of 50 people from the partners.

Axillium will operate the ASCEND program office at GKN’s Global Technology Centre, Bristol, U.K.. Axillium also will help manage the finances of the program and partner integration. Searle says Axillium will manage ASCEND’s events as well, including quarterly meetings and activities, which will rotate from region to region in the U.K.

The fundamental deliverable of ASCEND is a capability, says Searle, with emphasis on high-volume composites manufacturing for the commercial aerospace, automotive and urban air mobility (UAM) markets. For commercial aerospace, in particular, the goal is to develop technologies to meet a production rate of 80 shipsets per month.

“Being able to produce those at rate in an automated, highly integrated digital driven process is our true goal,” Searle says. “So we have a digital theme. We have an advanced materials theme. We have some multifunctionalism and we have some integrated structures.”

Searle also notes that there is a skills and workforce development component: “You need to start bringing the right type of people to the fore. So we do have an underlying activity with the National Composites Center on education and sustainability specifically… Rather than wait for the technology to come to market and then recruit people, we have a principle of underpinning the R&D with people and training as well, which again, is a measure that we report to through funding. So I think that's a really important bit, and without the people, we will not be able to operate the facilities — the production, the capability won't exist.

Searle says ASCEND will have a presence at industry and end market trade events and major air shows, like Farnbrough. Further, when allowed, ASCEND will report on its progress.

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

Read MoreRead Next

Hexcel joins ASCEND project for composite development acceleration

Hexcel to collaborate and further develop HexPly, HiMax and HiTape technologies and incorporate its Liquid Composite Molding (LCM) products into the project framework.

Read MoreGKN Aerospace and partners launch ASCEND to accelerate high-volume composite technologies

£39.6 million ASCEND consortium to strengthen the U.K. industry’s position as the leader of next-generation sustainable aircraft and future mobility technology.

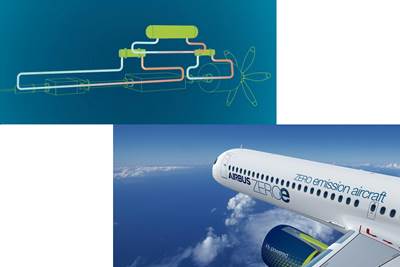

Read MoreAirbus ASCEND program to explore liquid hydrogen and superconductivity for zero-emission aircraft

Cryogenic hydrogen as cold source for lightweight, low-electrical loss powertrain, with composite materials as possible insulation.

Read More