Pultrusion Process for Composites

Pultrusion is a manufacturing process integral to composite production, involving the continuous pulling of reinforcing fibers through a resin bath and then through a shaping die, where they are cured and formed into a constant cross-sectional profile. This method, known for its efficiency and precision, is commonly used for producing continuous profiles with consistent dimensions and exceptional strength.

Latest Pultrusion Articles

VIEW ALLExel Composites supplies fiberglass profiles for Foton electric buses

Partnership with Chinese automotive manufacturer will see the implementation of pultruded profiles in various bus models, backed by weight savings, complex geometries and long life.

Read MorePultrusion, pull-winding showcase high-volume composites production

JEC World 2024: Exel Composites offers attendees a chance to engage with company experts and learn more about continuous composite manufacturing processes across various industries.

Read MoreServo-based pultrusion machines for composite profile production

CAMX 2023: Kent Pultrusion is displaying its turnkey ServoPul servo-driven pultrusion lines and secondary equipment for handling composite profiles.

Read MoreComposite profiles bring consistent quality to Ant-X drones

Italian drone solutions provider enlists Exel Composites to deliver pultruded and pull-wound profiles that support prototype drone structure designs.

Read MoreFST-rated thermoset resin with rapid, tunable cure is designed for infusion

CAMX 2023: The nonhalogenated Harp Rapid resin system presented by Trimer Technologies achieves a low-temperature, tunable cure while attaining high mechanical properties, demonstrating its effectiveness in aerospace applications.

Read MoreBiocomposite for mobile architecture, low load-bearing applications

The German Institutes of Textile and Fiber Research and partners have developed a biocomposite well suited for support profiles and connecting nodes in construction applications.

Read MoreKnowledge Centers

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

This CW Tech Days event will explore the technologies, materials, and strategies that can help composites manufacturers become more sustainable.

LEARN MORELatest Pultrusion News And Updates

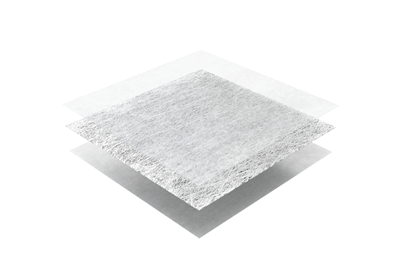

Ilium FLEXmat fiberglass is suitable for pultrusion processes

Latest long chopped glass fiber reinforcement technology enables high temperature exposure, material stretching and chemical resistance, making it a safer cleaner option for pultrusion manufacturing.

Read MoreExel Composites pultruded rods enhance Umbrosa parasol durability

The Belgium-based manufacturer chose pultruded fiberglass ribs for many of its umbrella and parasol designs to effectively endure exposure to high wind speeds, saltwater, rain and UV.

Read MoreGerman consortium develops biopolymer-based Cellun composite

German Institutes of Textile and Fiber Research (DITF) and partners present a conventional composite material alternative using cellulose that can be processed using industrial processing methods.

Read MoreCreative Composites Group introduces H-5 rated FRP bridge decking

High-strength pultruded SuperDeck Lite gives ambulances and maintenance vehicles access to trails, bridges, boardwalks and sidewalks

Read MoreTNL Applied Composites Manufacturing course begins February 2023

Hybrid, seven-session class helps participants learn the tricks of different composites manufacturing technologies from wet layup to pultrusion.

Read MoreKent Pultrusion expands manufacturing facility to address the growing composite market

Doubled capacity increases the fabrication, machining and assembly capabilities for Kent’s servo motor-controlled ServoPul pultrusion lines.

Read MoreFeatured Posts

Robotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreSeat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

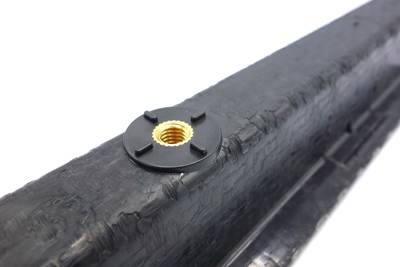

Read MoreNovel processes for hybrid thermoset-thermoplastic pultruded parts

CFRP pultrusion and pullwinding specialist Epsilon Composite combines thermoplastic overmolding with traditional thermoset processes, demonstrated through aircraft struts and industrial applications.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreTwenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

WatchComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

WatchFAQ: Pultrusion

What is pultrusion?

Pultrusion is a manufacturing process integral to composite production, involving the continuous pulling of reinforcing fibers through a resin bath and then through a shaping die, where they are cured and formed into a constant cross-sectional profile.

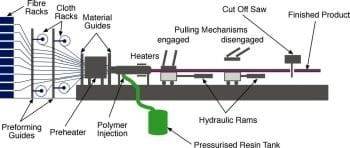

What is the pultrusion process?

In a pultrusion process, fibers are pulled from a creel through a resin bath and then on through a heated die. The die completes the impregnation of the fiber, controls the resin content and cures the material into its final shape as it passes through the die. This cured profile is then automatically cut to length. Fabrics may also be introduced into the die to provide fiber direction other than at 0 degrees. Although pultrusion is a continuous process, producing a profile of constant cross-section, a variant known as “pulforming” allows for some variation to be introduced into the cross-section. The process pulls the materials through the die for impregnation, and then clamps them in a mold for curing. This makes the process non-continuous, but accommodating of small changes in cross-section.

Source: Pultrusion: The basics

What are some advantages to pultrusion?

Advantages to pultrusion include:

- This can be a very fast, and therefore economic, way of impregnating and curing materials.

- Resin content can be accurately controlled.

- Fiber cost is minimized since the majority is taken from a creel.

- Structural properties of laminates can be very good since the profiles have very straight fibers and high fiber volume fractions can be obtained.

- Resin impregnation area can be enclosed thus limiting volatile emissions.

The disadvantages include that the process is limited to constant or near constant cross-section components, and costs for heated dies can be high.

Source: Pultrusion: The basics

.jpg;maxWidth=300;quality=90)