Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Editor’s note: This content was originally published on NetComposites.com. NetComposites was acquired by CompositesWorld’s parent company, Gardner Business Media, in February 2020.

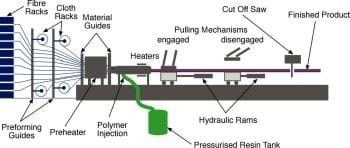

In a pultrusion process, fibers are pulled from a creel through a resin bath and then on through a heated die. The die completes the impregnation of the fiber, controls the resin content and cures the material into its final shape as it passes through the die. This cured profile is then automatically cut to length. Fabrics may also be introduced into the die to provide fiber direction other than at 0 degrees. Although pultrusion is a continuous process, producing a profile of constant cross-section, a variant known as “pulforming” allows for some variation to be introduced into the cross-section. The process pulls the materials through the die for impregnation, and then clamps them in a mold for curing. This makes the process non-continuous, but accommodating of small changes in cross-section.

Material options include generally any epoxy, polyester, vinyl ester or phenolic resin combined with any fiber type. Core materials are not generally used.

Advantages to pultrusion include:

- This can be a very fast, and therefore economic, way of impregnating and curing materials.

- Resin content can be accurately controlled.

- Fiber cost is minimized since the majority is taken from a creel.

- Structural properties of laminates can be very good since the profiles have very straight fibers and high fiber volume fractions can be obtained.

- Resin impregnation area can be enclosed thus limiting volatile emissions.

The disadvantages include that the process is limited to constant or near constant cross-section components, and costs for heated dies can be high.

Typical applications include beams and girders used in roof structures, bridges, ladders and frameworks.

For the latest on pultrusion and its applications, see compositesworld.com/zones/pultrusion.

Related Content

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Composite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.