Thermoplastics

Orbital continues to progress toward commercialization

Orbital Composites is pursuing a variety of collaborative projects to apply its Orbital S robotic additive manufacturing system.

Read MoreSTUNNING project successfully develops 8.5-meter thermoplastic fuselage skin

Clean Sky 2 project under the MFFD program produces two segments of an 8.5-meter-long, 4-meter-diameter thermoplastic fuselage skin via NLR’s in-house AFP machine, with consolidation plans this summer.

WatchMarkforged next-generation fiber-reinforced 3D printer

Markforged will debut its newest continuous fiber-capable 3D printer, the FX20, at Formnext in November 2021.

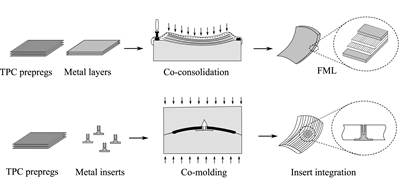

Read MoreTPRC publication studies the effects of grit-blasting on titanium-thermoplastic composite joints

Researcher Vanessa Marinosci studies the correlation between mechanical performance and titanium surface morphology of co-consolidated Ti6Al4V-C/PEKK joints.

Read MoreBieglo Group thermoplastic polymer supports project to 3D print structures on the moon

High-performance Aurum resin, combined with regolith material, will be used to create a printing material mixture that holds up under the harsh lunar environment.

Read MoreCEAD launches new E50 Robot Extruder for larger 3D-printed composites

New option offers higher material output (e.g., 84 kg/hr) and thermoplastic melt temperatures up to 400°C.

Read MoreDiab acquires SABIC’s ULTEM foam production line

The recyclable PEI thermoplastic foam will be incorporated into Diab’s portfolio under Divinycell U to be produced, sold and further developed.

Read MoreSABIC, Local Motors conduct feasibility study for reprocessed, 3D-printed thermoplastic parts and shavings

Anticipating the wider adoption of LFAM, the study explored more sustainable alternatives to landfilling large, printed parts, with results indicating the potential for material reuse.

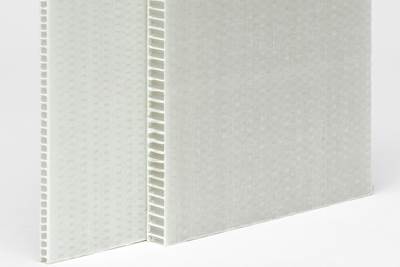

Read MoreThermHex, EconCore invest in automated production for PP honeycomb sandwich, recycled PET products

Targeting recycled and high-performance thermoplastic options, automated R&D lines increase volume and speed for honeycomb, sandwich panel and finished part production.

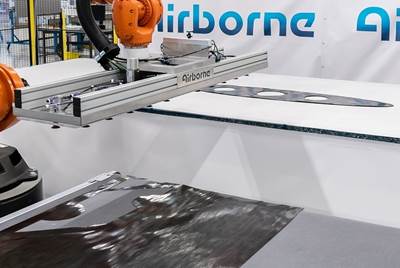

Read MoreAirborne introduces automated pick-and-weld preforming system

The robust, flexible and versatile three-step system handles a range of dry fiber and thermoplastic composite material forms for high output, improved efficiency and reduced waste.

Watch