ORNL, AddUp collaborate on additive manufacturing for tooling applications

As part of an R&D agreement, AddUp and the Oak Ridge National Laboratory are developing industrial laser powder bed fusion technology for complex tooling.

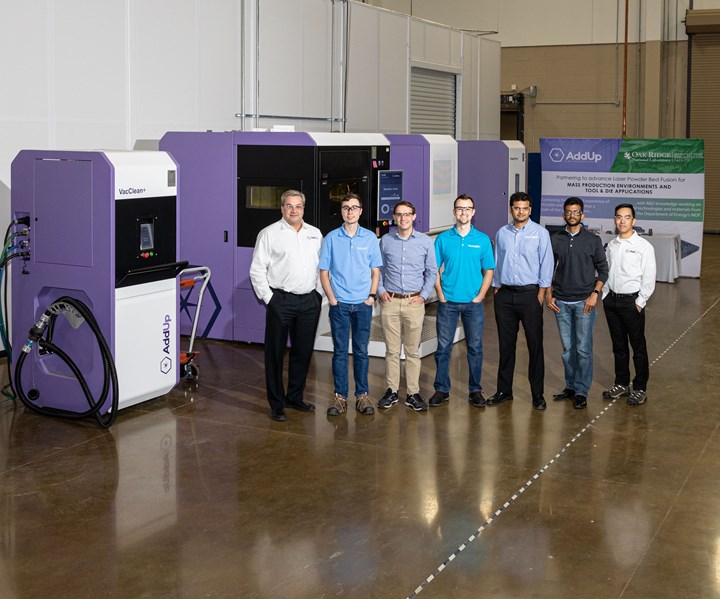

Members of the Oak Ridge National Laboratories and AddUp team collaborate to target the advancement of materials processes for additive manufacturing tooling applications. Source | AddUp

The U.S. Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL; Oak Ridge, Tenn., U.S.) has partnered with global machine and additive manufacturing (AM) solutions provider AddUp Group (Greenville, S.C., U.S.; a joint venture between Fives and Michelin) for the advancement of additive moldmaking technology for tooling applications.

As part of the $2.7 million cooperative research and development agreement (CRADA), AddUp is developing industrial laser powder bed fusion (LPBF) technology at the DOE’s Manufacturing Demonstration Facility (MDF) at ORNL, with a specific focus on the advancement of metal AM applications for complex tooling.

ORNL contributes an in-depth understanding of material properties and process parameters that leverages in-situ data analytics and advanced machine learning tools. Using the cutting-edge methods of characterization present at the MDF, the CRADA will also expedite the delivery of validated AM process recipes and a deepened comprehension of the microstructural properties of AM tool steels.

According to AddUp, the combination of expertise from both companies enables a robust approach to fabricate complex mold and die tooling that will lead to reduced cycle time and optimized, repeatable performances.

The CRADA focuses on the development of breakthrough solutions for the geometric constraints and limitations (such as overhang angles, thin walls and process repeatability) that impede metal AM from becoming a widely adopted method of manufacturing for tooling and mass production environments.

As one example, AddUp and ORNL will explore the impact of using complex cooling channels to solve challenges in injection molding applications. According to AddUp, subtractive, conventional moldmaking methods that use traditional machinery hinder the design freedom of intricate channels within the mold. This collaborative effort aims to deliver a technology capable of improving pre-existing processes of manufacturing conformally cooled molds with optimized mechanical properties, productivity and quality for enhanced performance in high-volume production environments.

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

Thermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)