MaCoIMA project to develop the potential of composites additive manufacturing

The MaCoIMA (Innovative Composite Materials from Additive Manufacturing) project aims to develop new composite and hybrid materials for use in high-performance sectors such as advanced mechanics and aeronautics.

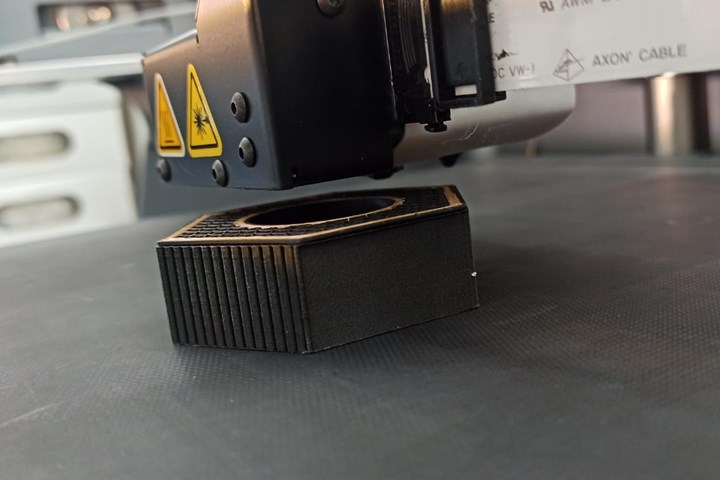

Photo Credit: Ecor International S.p.A

Ecor International SpA (Schio, Italy) joins the MaCoIMA (Innovative Composite Materials from Additive Manufacturing) project, which aims to develop and implement advanced composite and innovative hybrid materials made with additive manufacturing (AM) technologies. The project was launched with the POR-FESR Veneto Region ACTION 1.1.4 to “support collaborative R&D activities for the development of new sustainable technologies, new products and services,” and involves Italy-based partners Compositex s.r.l., the Dipartimento di Ingegneria Industriale at the University of Padua and Rise Technology s.r.l.

According to Ecor International, AM’s development potential is well known and has been acknowledged by the scientific and industrial world. However, it is still limited by the scarce knowledge on material properties, which makes design and degree of reliability uncertain with respect to potential applications.

The goal, therefore, is to develop new materials in both composite and hybrid form for their use in high-demanding sectors such as advanced mechanics, aeronautics, automotive and medical. In addition to the development of AM processes for composites, a study will be undertaken to develop joining procedures between materials with different structures and properties, both in the process and in the post-process phase. This stage reportedly enables the evaluation of the integration of conventional manufacturing processes within AM production systems and will help to better understand the “coexistence” with ceramic or metallic materials.

As reported by Domenico Stocchi, project coordinator, the MaCoIMA project’s strength is represented by its high technical level and the industrial potential of the materials developed. Stocchi notes that the project will also build a specific know-how for Industry 4.0, defining new material and process criteria necessary for the development of innovative technologies.

In this sense, the research focuses on a multidisciplinary approach that involves the use of cross-sectional skills, from the study of materials to the additive process, to structural design and modeling.

The MaCoIMA project consists of several phases that are necessary for the implementation of the innovation process which include:

- Integrated design of the material-process system geared to the industrial target of high-performance materials

- Development of prototypes in AM

- Marketing of innovative materials on the market.

In particular, Ecor International’s role is transversal to all lines of research. Its technical-scientific skills will be made available from the design phase of advanced materials to the optimization of smart manufacturing processes and their integration with conventional production also in the development of hybrid metal/composite materials. The design will be extended to innovative solutions in which 3D printing technologies will be exploited, for example, for their potential in terms of design freedom, mechanical performance of materials and lightweighting.

The company will also be engaged in the phases of characterization and determination of the chemical-physical properties, mechanical new materials, as well as the development of functional coatings for the protection and/or extension of the use of such materials in other fields of application.

Related Content

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.