KraussMaffei optimizes SCS process with quick nozzle change module

Efficiency, resource optimization and environmental responsibility are key focuses behind the seamless switch between flat and round jet nozzles, used for spraying polyurethane onto composite components.

KraussMaffei (Parsdorf, Germany) is extending the capabilities of its structural component spraying (SCS) process for applying reactive polyurethane (PU) via a nozzle change technology. The flexible solution addresses the balance between efficiency and resource conservation when using SCS for automotive (e.g., loading floors and car roofs) and structural component production.

According to KraussMaffei’s website, in the SCS process, “layers made up of fiber mats and honeycomb cores are sprayed with unreinforced PU, inserted into a mold and compression molded. This further development of LFI/honeycomb technology reduces the thickness and weight of the cover layers to further optimize the lightweight construction.” By enabling the swift interchange between flat and round jet nozzles and vice versa, KraussMaffei reports reduced material waste and enhanced precision.

“Efficiency in our spraying process is vital for sustainable production,” Sergi Salart, South Europe industrialization manager at Trèves (Paris, France), an automotive customer of KraussMaffei’s “KraussMaffei’s nozzle changing system has significantly enhanced our operations in Treroc, Morocco, and will soon be implemented in our Romanian plant as well.”

The ability to seamlessly switch between nozzles offers multiple advantages over conventional methods, KraussMaffei contends. While the flat jet nozzle covers larger areas rapidly (throughput of ~50 grams/second and maximum spray width of 120 millimeters), the round jet nozzle precisely targets and reinforces edge zones (up to 130 grams/second and works without air support), optimizing material use. The rapid transition facilitated by the nozzle change module also reduces downtime to seconds, streamlining the production process. Additionally, the technology’s adaptability to varying material quantities ensures optimal resource us, reducing material waste and production time.

Beyond efficiency gains, the environmental impact is said to be significant. For instance, the reduced spraying time for a 2,200 × 1,200-millimeter component can lead to up to 30% less material consumption, minimizing waste and supporting sustainable practices.

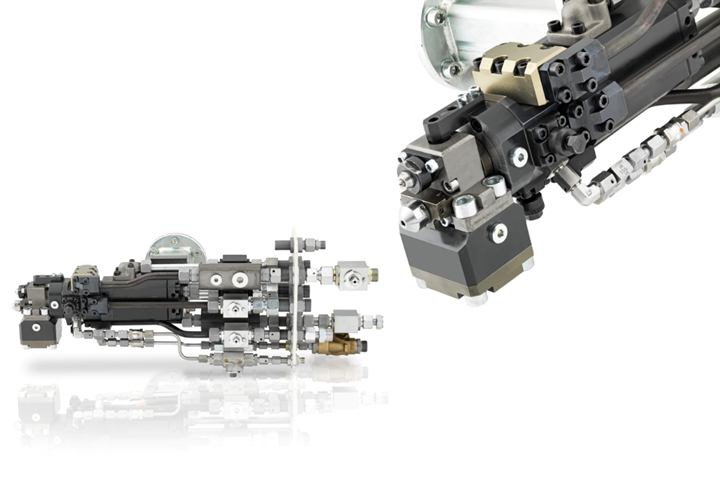

Importantly, the nozzle change module is fast. For example, if a user starts with the flat jet nozzle and completely sprays the loading floor, the discharge channel is cleaned in around 3 seconds using compressed air. The change to the round nozzle itself is carried out hydraulically by pushing the second channel geometry into position. This only takes around 100 milliseconds and the process continues. The mixing head is equipped with spring-loaded nozzles or nozzles with vario equipment in order to be able to handle the variable material quantities. The latter work with an air cushion located in a gas chamber behind the nozzle. In the event of fluctuations in the component throughput, vario nozzles balance the pressure better and achieve optimum process parameters with different discharge rates.

KraussMaffei’s established process began with operation of the nozzles (each with their own mixing head) on a robot. This was followed by a mixing head with a changeover device and finally, a changeover module, with which it is possible to swivel from one nozzle to the other within a few seconds. Patent applications have been filed in various countries, some of which have already been granted.

“Investing in KraussMaffei’s PUR systems with changeover technology has proven not only reliable but also aligns with our sustainability objectives,” Salart emphasizes. “Our success with these low-maintenance systems has us planning further implementations.”

Anyone planning a new system for PUR processing would be well advised to invest in changeover technology right away, as emphasized by Sergi.

Read Next

Composites in Class A body panels: Evolution continues

Low-density SMCs lead the way as fiber-reinforced polymers make headway in auto components that must please the eye.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreKraussMaffei expands LFI and SCS processing with shuttle mold carrier

At the Munich-based TechCenter, the MX mold carrier is developed to improve fiber injection and spraying capabilities including for large, Class-A components.

Read More