Low-rate layup tools made cost-effective with high-density polyurethane foam blocks

Nemesis Air Racing, an air racing team and kit-plane company owned and operated by Jon and Patricia Sharp, use prebonded closed-cell, polyurethane foam blocks to build the Nemesis NXT.

Nemesis Air Racing (Oro Valley, Ariz.) is an air racing team owned and operated by Jon and Patricia Sharp. Formerly a composites engineer at Lockheed Martin Skunk Works (Palmdale, Calif.), Jon Sharp is a legendary air racer: He won the Reno Air Racing National Championships nine consecutive times in a tiny International Formula 1 racing aircraft, dubbed Nemesis, which he and his team developed and fabricated in the early 1990s. The most successful aircraft in air-racing history, the original Nemesis is on display in the Smithsonian National Air and Space Museum (Washington, D.C.). When Sharp decided to build a larger composite racer, the Nemesis NXT, an unexpected rule change mandated that each participating aircraft had to be available for purchase as a kit. Fortunately, the Nemesis name ensured that the required five kits were quickly sold. Sharp and his team were then faced with producing the carbon fiber/epoxy composite kit elements from CAD file data.

Based on his extensive experience at Skunk Works, Sharp understood the benefits of soft tooling for prototyping and limited production: “We were drawn to high-density polyurethane because of the greater level of design flexibility that was available. The inevitable design changes were much less of a headache than with metal tools.”

Coastal Enterprises Co. (Orange, Calif.) supplied Sharp with Precision Board Plus, a 20 lb/ft3, closed-cell, polyurethane foam in customized, prebonded shapes, to create the molds for the NXT’s horizontal and vertical tail, leading edges, interior components and the craft’s 90-gal gas tank. The prebonded shapes saved time and labor during CNC-machining with standard cutting tools, because less material had to be machined to achieve the final mold shapes. As Sharp told Coastal Enterprises, “The foam molds gave us our most accurate airframe ever produced. The tight cell structure and ease of machining enabled us to bring our first computer-designed aircraft to life.”

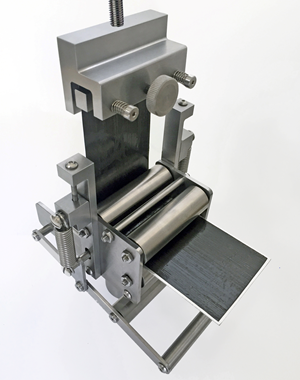

“If you make the decision to buy metal tooling, you’re constrained by a lot of factors — higher cost, size and weight and overall lead time for the tool build,” contends Coastal Enterprises president Chuck Miller. “High-density urethane foam offers much more flexibility and speed, and the coefficient of thermal expansion can be easily compensated for.” Precision Board Plus reportedly is suitable for tooling applications up to 300°F/149°C, is available in densities from 4 lb/ft3 up to 75 lb/ft3, and can be autoclave-cured, says Miller. He also explains that Coastal’s ability to bond polyurethane foam blocks together in the approximate shape of a final tool (see photo, lower left) prevents bondline voids, which can cause “chunking” of the material during machining (custom mandrels in any size are also on offer): “We formulate our own EP76 epoxy adhesive to match the density of the material,” says Miller, “which helps reduce collet chatter witness lines in the part.”

Miller adds that, in the past, polyurethane foam tools earned a reputation for “inhibiting cure” of carbon/epoxy prepregs due to its out-gassing during heating. In fact, he says, this inhibition of cure can also occur due to out-gassing of some tool sealers. Any out-gassing from the tool during heating, whether it originates from the tooling board, or any sealer, filler, or etc., can react with the epoxy resin and inhibit the composite cure. "Precision Board Plus, in both PBLT 200ºF and PBHT 300ºF formulations, have proven over the years they do not out-gas, contends Miller. "All high-density urethane tooling boards are a fairly good insulator and, therefore, not a good heat conductor and so do not readily conduct temperature." They need time for temperature change (i.e., ramping time, for temperature absorption or release). The typical temperature ramping time for high-density urethane is two minutes per degree Fahrenheit, going up in temperature, and one minute per degree Fahrenheit coming down. "Ramping both directions is critical to allow the CTE expansion and contraction to normalize without causing stress risers and possible cracking. This also allows some extra time for complete layup cure," he notes, adding, "It is always recommended to discuss specific composite applications with the manufacturer prior to layup."

Related Content

Composite prepreg tack testing

A recently standardized prepreg tack test method has been developed for use in material selection, quality control and adjusting cure process parameters for automated layup processes.

Read MoreMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreJEC World 2022, Part 3: Emphasizing emerging markets, thermoplastics and carbon fiber

CW editor-in-chief Jeff Sloan identifies companies exhibiting at JEC World 2022 that are advancing both materials and technologies for the growing AAM, hydrogen, automotive and sustainability markets.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)