Composites slake the world's thirst

As the global thirst for drinkable water increases, the composites industry is drinking in the tremendous possibilities in seawater desalination.

Seventy-one percent of the earth’s surface is covered by saltwater. People living on the remaining 29 percent need fresh water to sustain life. But the World Health Organization (WHO, Geneva, Switzerland) estimates that there are more than 1 billion people who lack fresh water. By midcentury that number is expected to swell to 4 billion. These startling realities admit no charge of hyperbole in the prediction that exponential growth is on tap for world seawater desalination.

Remarkably, almost 60 percent of the world’s population lives less than 36 miles/60 km from a seacoast. Desalinated seawater is poised to become one of the main alternative freshwater resources in those regions. But market growth projections, in fact, take into account not only the increasing world population — projected to reach 7.52 billion by 2020 — and data about its proximity to seawater, but also the impacts of drought, urbanization, agricultural irrigation and, in some cases, saline invasion into existing freshwater resources. The market for products and services used to convert seawater into fresh water for municipal drinking water and other uses was estimated to be about $2 billion (USD) in 2000. Market research firm The Freedonia Group Inc. (Cleveland, Ohio) predicts that the desalination market will expand to more than $18 billion by 2020.

A truly global market

Desalting has actually been around for more than 2,000 years, says Ian Watson, executive director of the American Membrane Technology Assn. (Stuart, Fla.). Historically, it has been used aboard ships and was especially important in 19th Century colonial expansion, which required fresh water for ships and colonies. In the 20th Century, the corrosive effects of seawater on desalination equipment spurred the use of plastics. With little fanfare, composite materials have been used for more than 30 years in desalination plants around the world, primarily in piping and connections (pipeworks) and other components that come into direct contact with seawater.

Although numerous desalination treatment and recycling technologies have proliferated in a multitude of submarkets, this overview focuses on what is probably the biggest user of composites — desalination of seawater for use as fresh water by reverse osmosis.

Osmosis occurs when two solutions, composed of solute (dissolved inorganic solids, such as salt) mixed with a solvent (in this case, water) are separated by a semipermeable membrane. The solvent molecules move through the membrane in the direction of high solute concentration until the solute/solvent ratios are equal. Osmosis would create two solutions of equally salty water. The seawater reverse osmosis (SWRO) process, as the name implies, reverses natural osmosis. It begins by bringing seawater (feed water) at low pressure through a pretreatment filtering system that removes suspended solids. The pretreated water then is pressurized and pumped through a series of semipermeable reverse osmosis (RO) membrane elements at about 900 to 1,200 psi (60 to 82.5 bar). On the other side of the membrane, fresh water is passed. Because of the pressure, the water molecules in the seawater (the high solute concentrate) pass through the membrane in the direction of the low solute concentrate — in this case, the passing fresh water (the product stream) and joins it — leaving the salt and other dissolved solids behind.

SWRO is described as a separation process, rather than a filtration process. “RO is a traffic cop of water,” quips Doug Eisberg, director of business development for Avista Technologies (San Marcos, Calif.), which supplies specialty chemicals and technical support services for the membrane separation industry. “RO sends all the purified water to the product stream, and sends the bacteria, viruses, salt and other undesirables [collectively known as brine, or concentrate] on through to the next membrane,” says Eisberg, where further separation occurs.

SWRO is expected to dominate and drive the desalination industry in coming years because it requires substantially less energy than other popular desalination technologies, such as multistage flash (MSF) and multieffect distillation (MED). These are high-energy thermal processes that rely on heating the seawater to produce steam. Only the water molecules are gasified, leaving the salt and impurities in the solution. The steam is transported to a cooling tank where the desalinated water condenses. Further, SWRO usually incorporates energy recovery devices that capture hydraulic energy from the process and convert it into rotary power for the high-pressure pumps.

Going to great lengths

SWRO plants around the world use miles and miles of corrosion-resistant fiberglass-reinforced polymer (FRP) low-pressure piping as a distribution network, primarily over land, to carry seawater from the sea to the plant, to distribute the potable water that is produced, to carry the brine back to the ocean, and for internal plant treatment piping and energy recovery devices.

Peter Kirkwood, managing director for ResiGlass Pty. Ltd. (Winthrop, W. Australia), explains, “FRP is the material of choice for medium- to large-size plants, while smaller plants tend to use high-density polyethylene [HDPE].” FRP is more cost-effective than HDPE in the larger-diameter pipes generally used in the biggest plants. FRP materials and processes can be tailored to meet specific mechanical property requirements and have the additional advantages of corrosion and chemical resistance, flexibility and the capacity to withstand mild shock.

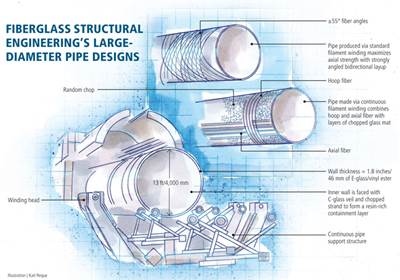

FRP pipes are, primarily, filament wound glass/polyester. For aboveground applications, helical filament winding on a fixed-length mandrel is most popular because it can be tailored to achieve the desired hoop-to-axial strength ratio by customizing the angle of wind, making it ideal for restrained joining, Kirkwood explains. (Restrained joints feature couplings, tie rods or other types of restraints.) For pipes destined for burial underground, continuous filament-wound pipe is generally used because it can be produced in a greater variety of lengths and diameters. (Read more about continuous filament-wound pipe in “Designing for high pressure: Large diameter underground pipe,” under "Editor's Picks," at top right.) Often it is also more price competitive and lends itself better to the use of unrestrained joints, such as mechanical seal couplings.

FRP joints and fittings are generally made by hand layup, although some flanges and fittings are filament wound, depending on the cost advantages.

FRP also is commonly used to construct storage tanks and piping used in desalination plants for sodium hypochlorite (NaOCl), often used in chlorination of desalination process water, and for sulfuric acid, which can be very difficult to store in metal “but can readily be handled in fiberglass/epoxy vinyl ester tanks and piping at ambient temperatures and concentrations below 50 percent,” says Thomas Johnson, corrosion industry manager for resin producer Ashland, LLC (Dublin, Ohio).

There is little FRP pipe in the undersea portion of intake and discharge systems, however. Typically seawater is pumped up from seabed intake equipment through concrete tunnels, often lined with polyvinyl chloride (PVC) or other plastic to decrease friction and discourage attachment of crustaceans.

There are exceptions. One is the velocity intake system on the seabed at the Gold Coast, Australia, plant, which is nearly all FRP composite material with a frame of stainless steel, according to Gary Crisp, global business leader – desalination for GHD Global Engineering Consultants (Perth, Australia). “A mile-long concrete tunnel from the intake system commences from a vertical, composite-lined intake shaft incorporating velocity cap open seawater intake,” Crisp says. (The velocity cap, a concrete cover slightly raised over the vertically oriented intake pipe, redirects seawater into the pipe horizontally, reducing the risk of fish getting sucked in and then stuck on the internal intake screen.) “A second mile-long concrete tunnel terminates in a vertical, composite-lined outfall shaft, connected to diffusers, that returns seawater concentrate back to the sea.” Custom-designed diffusers are typically used to spread out concentrate as it is discharged.

The composite pipelines for the 2.2m/7-ft intake and 1.6m/5-ft outfall shafts (see photo) were manufactured by helical filament winding in 12m/39-ft sections by RPC Technologies Pty. Ltd. (Seven Hills, New South Wales, Australia). Ribs wound over polyurethane foam cores add stiffness. RPC set up a temporary manufacturing plant and shipped pipes for undersea installation by barge, lowering them into a trench on the seabed. The pipe section under the sea was also buried with crushed stone, which was dropped from a barge. Divers then installed bell and spigot joints with double O-rings and plastic locking cord.

FRP is not used for the high-pressure piping that forces seawater at pressures up to 1,200 psi/82.47 bar through the RO separation process, mostly because composite joints and couplings associated with such high-pressure systems are considered impractical. The pressure pipework is almost always superduplex or superaustenitic stainless steel or, sometimes, titanium. But Crisp would like to see more research into the potential for use of high-strength fibers, such as carbon and aramid, to make high-pressure pipes and couplings because corrosion is still an issue, even with corrosion-resistant grades of steel. “Corrosion is a real problem for steel in this environment due to galvanic attack commonly found in seawater and brackish water environments, but composites made with epoxy vinyl ester resins such as Ashland’s Derakane 411 or Hetron 922, or isophthalic resins such as Aropol 7334, perform admirably in desal piping applications,” Johnson says.

Basic SWRO construction

Also FRP are the pressure vessels that enclose RO membrane elements. Multiple RO elements can be encased within each pressure vessel, and the vessels can be grouped together to use common pipes for feed water, fresh water and concentrate. Each grouping is called a train, and the trains are arranged in racks.

Today these pressure vessels are mostly precision filament-wound. Eisberg points out that filament winding on a precision mandrel produces a consistent inside diameter (ID) with a smooth surface. By comparison, a comparable metal pipe has neither a smooth inner surface nor a consistent diameter. This is a critical factor when installers must ensure a tight fit on the end closures that seal the joint where the membrane and pressure vessel meet.

This seal, sometimes called a brine seal, prevents the feed water from leaking outside the membrane. As seawater is pumped into the membranes, the fresh water separates, flowing through the RO membrane and into a product water tube at the centerline of the membrane element. These product water tubes are connected with O-ring seals and typically exit the pressure vessel at the end of the vessel. The brine concentrate is directed to a high-pressure concentrate port, usually located on the side of the pressure vessel, which then connects to a discharge pipe that ultimately carries the concentrate back to the sea.

The ports are metal flanges that attach to the sidewall of the vessel, and the industry demand for higher flows regularly requires enlarging the diameter of the exit port. This can be a challenge, says Chris Gargiulo, director of manufacturing engineering for pressure vessel filament winder ROPV (Harbin, China), because “we have to cut through the fibers in that area to install the port.” The area around the port, therefore, must be strengthened if the vessel is to meet test standards. “Some companies use a ±45° reinforcement mat, others use a unidirectional mat, and overwind and some companies wind additional plies to reinforce the area,” Gargiulo says.

Quality and safety issues

The high pressures used in RO demand high-quality materials and careful construction. After a series of catastrophic vessel failures in the early days of SWRO, strict standards for manufacture and testing were developed and published by the American Society of Mechanical Engineers (ASME, New York, N.Y.). To qualify for ASME code compliance, a filament-wound prototype must be cycled 100,000 times from zero pressure to design pressure (typically 1,000 psi/69 bar at 150°F/65.5°C minimum) without leakage. After that test, it must also withstand a pressure test of six times the design pressure to satisfy the safety factor for composite products.

These high standards are even more difficult to meet because of the increasing output volume from large SWRO projects. To meet market demands, ROPV winds as many as 200 pressure vessels per day, in various sizes, using fiberglass roving and epoxy resin. After winding, the mandrel is placed in an oven for a multistage cure. The cure duration depends on vessel wall thickness, resin chemistry and other variables. The process variables are closely monitored throughout winding and cure, and the degree of cure is verified by a differential scanning calorimeter (DSC).

For Singapore’s Changi NEWater Plant, built by Sembcorp Industries Ltd. (Singapore), ROPV supplied 1,980 units of 8-inch (203-mm) ID by 40-inch (1,016-mm) long high-pressure seawater pressure vessels. Each unit enclosed a train of 10 SWRO membranes. The Changi plant is not for SWRO but instead is used for water reclamation. It begins with extensive pretreatment of sewage and industrial wastewater, followed by RO, to produce high-quality water used primarily in process applications. NEWater offers a capacity of 60 million gal/day (MGD), or 228,000 m3/day, of fresh water, enough to meet 15 percent of Singapore’s fresh water needs (see photo).

For Singapore’s large urban population, RO technology has been a necessary solution, both for water reclamation and seawater desalination. Singapore’s national water agency, PUB, has developed a long-term plan to meet the country’s increasing fresh water demand. In addition to the Changi plant, the SingSpring 36-MGD (136,000-m3/day) SWRO plant in Tuas, Singapore, built by Hyflux (Singapore), began operations in 2005, and a second SWRO plant is under construction by Hyflux now, scheduled for completion in 2013. Known as Tuas II, the second plant will have capacity for up to 84 MGD (318,500 m3/day). Hyflux purchased filament-wound pressure vessels for the first Tuas plant from Protec Arisawa (Tokyo, Japan) but contracted with ROPV to provide 3,672 8-inch/203-mm ID, 1,000 psi/69 bar pressure vessels for the TUAS II plant.

“In today’s market,” Eisberg explains, “pressure vessels are treated as a commodity, and suppliers are making more vessels per hour than ever before, while the technology used to make these vessels is more complex than ever before. Experienced suppliers are now trying to reduce costs to remain profitable while trying to make the most complicated products they have ever made.”

Unfortunately, there has been concern recently that these standards are not being followed. “In addition, when new OEMs, end-users and inexperienced fabricators are factored into the equation, the separations industry is taking significant risk, perhaps without even realizing it.” Eisberg urges strict compliance with the fabrication codes “for the long-term well-being of the industry.”

Composites in RO membranes

Composites also make their way into the membranes themselves. For example, Changi’s NEWater Plant and both Tuas plants installed SWRO membrane elements made by Toray Industries Inc. (Tokyo, Japan).

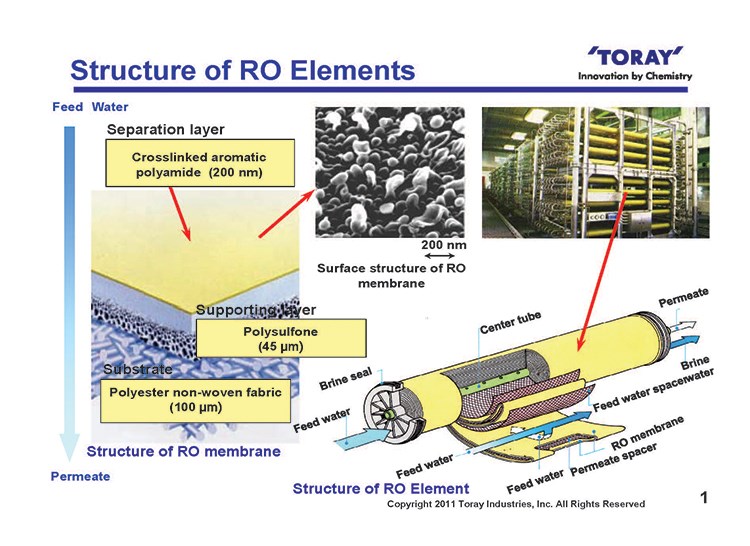

Spiral-wound composite RO membranes consist of a crosslinked, fully aromatic polyamide separation layer, with a supporting layer of polysulfone and a polyester fabric base, in a spiral-wound RO element, explains Peter Metcalfe, manager – applications engineering for Toray Membrane USA (Poway, Calif.).

The polyester fabric base is a nonwoven web that provides the backing and structural support for the membrane. To produce a smooth surface free of loose fibers, the fabric is calendered before it is further processed. “The calendering process is an important step for the backing fabric,” Metcalfe says. “Any loose fibers sticking up from the plane of the fabric will also penetrate the membrane layer. They are a weak point and a potential source of leakage in the polyamide layer, and they have to be removed.”

Although it provides basic structural support, the polyester web is too irregular and porous to provide a suitable substrate for the separation layer. The smooth surface of the base, therefore, is coated with a microporous layer of polysulfone engineering plastic (see illustration, p. 26). Then the polyamide separation layer is cast over the polysulfone-coated base to complete the membrane construction. It is typically 42-inches/1,067-mm wide and produced in rolls of 500m to 2,000m (1,640 ft to 6,562 ft) in length. The membrane is then combined with feed spacer material and permeate carrier material to create a spiral-wound element, typically using a fully automated process. In a final step, the element is overwrapped with glass/epoxy to increase its strength.

The installed capacity of Toray SWRO membranes over the past 25 years exceeds 1,110 MGD (4,200,000 m3/day) of fresh water from seawater in plants built worldwide by all the major OEMs — including Hyflux, GE Power and Water (Pittsburgh, Pa.), Doosan (Seoul, South Korea) and Veolia Water Solutions & Technologies (Saint-Maurice, France) — from the Hyflux plants in Singapore, to a 132-MGD (500,000 m3/day) plant in Algeria built in 2011, to a 396,258-gal/day (1,500 m3/day) plant in Yemen built in 2008 by Metito (Dubai, U.A.E.).

Another major RO membrane producer is Dow Water & Process Solutions (Edina, Minn.), a business unit of The Dow Chemical Co. (Midland, Mich.). DOW FILMTEC FT30 elements are in use at some of the largest seawater desalination plants in the world, including the 87-MGD (330,000 m3/day) capacity SWRO desalination plant in Ashkelon, Israel, a joint venture of Veolia, IDE Technologies Ltd. (Kadima, Israel), and Dankner-Ellern Infrastructures (now Elran DD, Herzliya, Israel). This was the first of several SWRO plants in Israel’s long-term national planning program to mitigate drought and meet increasing demands on its scarce water resources. FILMTEC elements also are used in the 120-MGD (456,000-m3/day) Hadera, Israel, plant, one of the world’s largest, and in three SWRO plants constructed by CH2M HILL (Denver, Colo.) for Sharjah Electricity and Water Authority (SEWA, Sharjah, U.A.E.). The membrane housings are ASME code-compliant filament-wound CodeLine-brand pressure vessels from Pentair Process Technologies (Golden Valley, Minn.). All three SEWA plants use filament-wound FRP piping from Chemical Process Piping Pvt. (CPP, Mumbai, India).

Desalination in the U.S.

The U.S. Congress established the Office of Saline Water in 1952 for research into desalination technology, and the U.S. Department of the Interior, Bureau of Reclamation (BuRec, Denver, Colo.) is still active in this area. The U.S. is the largest user of the technology in the world, primarily for purifying brackish water rather than seawater, according to Peter Soeth, a spokesperson for BuRec Public Affairs. Today the U.S. leads the world in brackish water desalination, with plants in Florida, Texas, California and several states on the East Coast and in the West/Midwest. The U.S. has few seawater desalination facilities, however, the main reason apparently being lack of need. Until recently, “the fresh water supply has never been at enough risk to warrant the expense of building and operating a seawater desal plant,” explains Kevin Price, advanced water treatment research coordinator for BuRec. The cost of fresh water in California, for example, is currently about $900 per acre/ft, and the cost of desalinated water is about $1,500 per acre/ft. One acre/ft equals 325,869 gal (1,233,548 liters).

Even with this price difference, the drought-prone coastal deserts of Southern California have spent more than 20 years eying access to the world’s largest reservoir, the Pacific Ocean. At last, one desalination project is on track to commercial productivity in the city of Carlsbad in San Diego County. Poseidon Resources (Stamford, Conn.) received final approval on Nov. 29, 2012, for its Carlsbad Desalination Project. The privately financed plant could supply up to 50 MGD (189,250 m3/day) of potable water for 300,000 San Diegans, providing the county with up to 10 percent of its water. Poseidon also is designing a 50-MGD (189,250-m3/day) SWRO plant at Huntington Beach in Orange County, Calif. If permits are granted by the end of 2013, the plant could be operational by 2015.

In Europe

To date, the largest desalination plant in Europe is an SWRO facility in El Prat del Llobregat (Barcelona, Spain), with a freshwater capacity of 52.8 MGD (200,000 m3/day). Built by Aguas de Barcelona (Agbar, Barcelona, Spain) and Degrémont Iberia (Bilboa, Spain) under contracts from the public utility Aigües ter Llobregat (ATLL), the plant has been operational since July 2009. It has the capacity to supply drinking water to about 1.5 million inhabitants in the region — almost 20 percent of the population. However, production depends on the total water in reservoirs, and as CT went to press, the plant was producing only 14 MGD (52,000 m3/day).

A total of 17,192 spiral-wound polyamide composite membrane elements were provided by Hydranautics (Oceanside, Calif.). Seven membranes are encased in each of 2,456 pressure vessels measuring 8-inches (202 mm) ID by 301.7 inches (7,663 mm) long and filament wound by Protec Arisawa Europe (Mungia, Spain) to meet the ASME pressure vessel code. Protec winds its vessels using E-glass and epoxy resin. Protec’s custom multiple-port technology provides an end port for fresh product water, a side port for feed water and another side port for discharge of concentrate.

Seawater is brought into the pumping station from 2,500m/8,202 ft out in the Mediterranean Sea through two 1,800-mm/71-inch diameter polyethylene pipes. A 2,000-mm/79-inch diameter FRP pipe then carries the feed water into the plant. FRP pipes and fittings were made by Protecciones Plasticas (Protesa, Barcelona, Spain) via continuous filament winding, using glass fiber and corrosion-resistant Atlac bisphenol A-based vinyl ester urethane resin from DSM Composite Resins (Schaffhausen, Switzerland).

Skimming the surface

Like a rock skipping across a still lake, this overview merely touches the surface of this huge and, without doubt, growing market. Its complexities, alternative technologies, expanding markets and opportunities for the use of composites go far beyond seawater reclamation. It’s a market that CT will watch and report on in greater depth as developments dictate.

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Designing for high pressure: Large-diameter underground pipe

Careful analysis is needed to ensure success of buried composite piping for industrial applications.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;maxWidth=300;quality=90)