Thermoplastics

Thermoplastics play a pivotal role in composite materials by serving as the matrix phase that binds reinforcements together. Unlike thermoset resins, thermoplastics possess the ability to soften and reform when heated, allowing for reshaping and recycling. They offer unique advantages such as high toughness, chemical resistance, and easy processing, making them versatile in various industries like aerospace, automotive, and consumer goods. Composites using thermoplastic matrices exhibit exceptional damage tolerance and are sought after for their potential in complex manufacturing processes like injection molding, enabling efficient production of intricate and high-performance parts.

Latest Thermoplastics Articles

VIEW ALLNIAR, KraussMaffei cooperation enables efficient aerospace aircraft conversion

Incorporation of FiberForm advance’s NIAR ability to convert metallic components to fiber-reinforced thermoplastic versions in cargo aircraft.

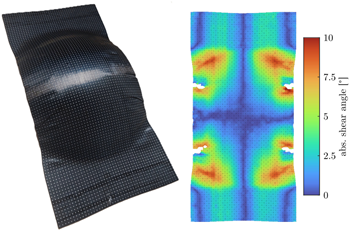

Read MoreTPRC announces press forming dataset publication

Recent research by academia aimed to validate composite forming simulations for press forming UD thermoplastic composite laminates.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

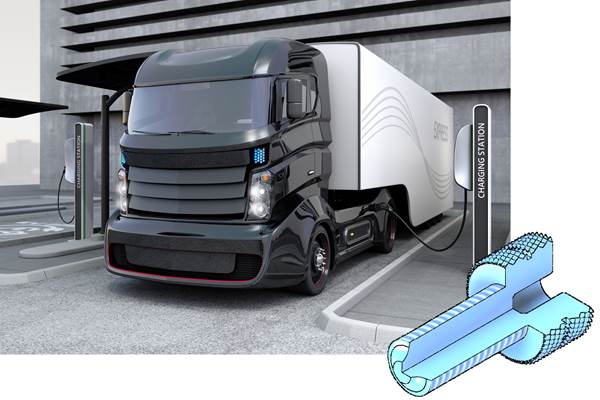

WatchCRP Windform composites show high affinity for electric insulation

GFRTP materials for 3D printing were subjected to dielectric constant and dielectric strength tests, indicating strength for use in electric applications like automotive.

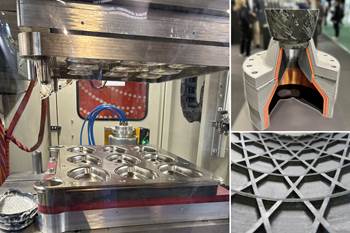

Read MoreHyWaSand demonstrates large-series production potential for automotive TP sandwich components

Storage compartment flap for truck interior produced via fully automated continuous fiber thermoplastic sandwich molding technology shows suitability for series manufacture.

Read MoreLast call for ITHEC conference abstracts

The thermoplastic composites event, taking place Oct. 9-10 in Bremen, Germany, is seeking oral and poster contributions before March 31.

Read MoreKnowledge Centers

CompositesWorld’s CW Tech Days: Infrastructure event offers a series of expert presentations on composite materials, processes and applications that should and will be considered for use in the infrastructure and construction markets.

LEARN MORE

Closed mold processes offer many advantages over open molding. This knowledge center details the basics of closed mold methods and the products and tools essential to producing a part correctly.

LEARN MORELatest Thermoplastics News And Updates

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

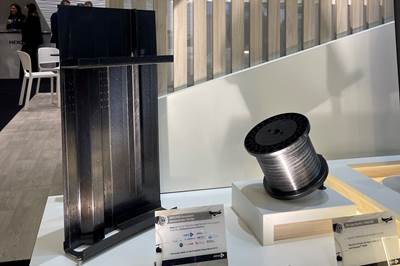

Read MoreHexcel, Arkema present CFRTP aerospace demonstrator in HAICoPAS

Project optimized design and production of UD composite tapes reinforced with a PEKK matrix, using a continuous in-situ welding (ISW) assembly system.

Read MoreFraunhofer IWS completes MFFD longitudinal fuselage joint using CONTIjoin technology

Thermoplastic composite upper and lower half shells for the Multifunctional Fuselage Demonstrator were welded using CO2 laser over a total length of 8 meters.

Read MoreToray announces Cetex TC915 PA+ thermoplastic tape

Strengthened polyamide-based unidirectional tape has been added to the Cetex portfolio, addressing high-performance applications.

Read MoreAimplas, Redit Ventures launch Lofith Composites

New company launch will focus on the design and creation of long fiber-reinforced thermoplastic pellets and UD tapes for automotive, aerospace and construction.

Read MoreDigital Composites Factory joint venture to grow thermoplastics manufacturing

Together, AFPT, Alformet and New Frontier Technologies are fostering a productive environment for development of well-designed thermoplastic composites via automation, innovative design and advanced 3D expertise.

Read MoreFeatured Posts

From the CW Archives: I see thermoplastics in your future

Thermoplastics are evolving quickly into larger structures and clearly will have a significant role to play in the next commercial aircraft program — whenever that’s announced. This edition of “From the CW Archives” looks back on a thermoplastics pioneer.

Read MoreEaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

WatchPlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

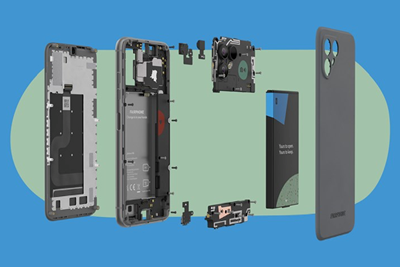

WatchComposites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

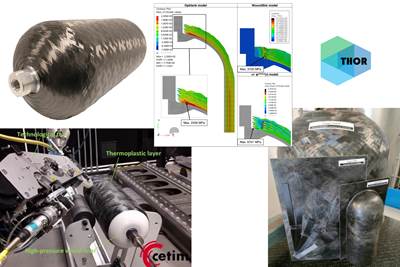

Read MoreUpdate: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)