Filament Winding

Filament winding is a specialized technique used in composite manufacturing, involving the precise and automated winding of continuous fibers onto a rotating mandrel or mold. This method allows for the creation of strong and seamless structures, optimizing the alignment and orientation of the fibers to meet specific design requirements. Filament winding is employed in producing cylindrical or conical composite parts, such as pipes, pressure vessels, and aerospace components, enabling engineers to tailor the strength, stiffness, and performance characteristics of the final product.

Latest Filament Winding Articles

VIEW ALLCarbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

WatchECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

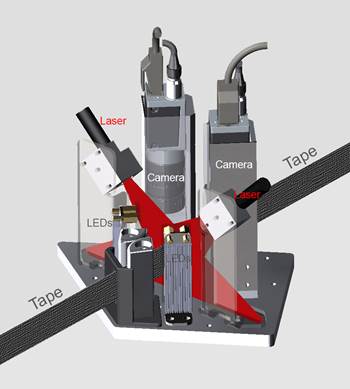

Read MoreDaQoTa project develops measuring head prototype for LATW inspection

Fraunhofer IPT, Taniq and Pixargus have proven the success of a measuring head capable of optimizing the reliability, security and efficiency of FRP pressure vessel manufacturing.

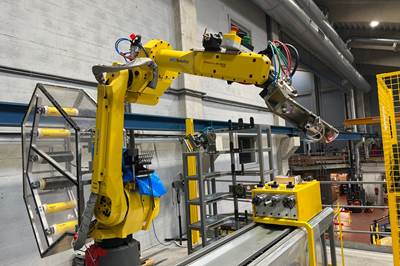

Read MoreAutomation, winding equipment meet evolving composite needs

JEC World 2024: Engineering Technology Corp. is exhibiting offerings ranging from high-speed filament winding equipment to integrated robotic solutions, in addition to new standard line of tape wrappers.

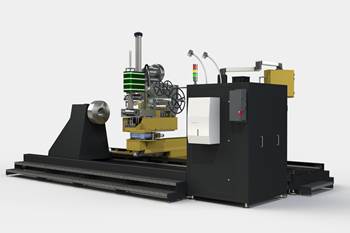

Read MoreFilament winders specialized for composites hydrogen vessel production

JEC World 2024: A pressure vessel for HydroExceed manufactured via a recently delivered multi-spindle filament winder displays Mikrosam’s expertise in filament winding equipment.

Read MoreAutomated winding machine supplier forges carbon fiber application growth

JEC World 2024: Custom-designed carbon fiber/epoxy components and automated fiber winding machine offerings will be on display, emphasizing CompoTech’s focus on designing and supplying turnkey composites technologies.

Read MoreKnowledge Centers

Closed mold processes offer many advantages over open molding. This knowledge center details the basics of closed mold methods and the products and tools essential to producing a part correctly.

LEARN MORE

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORELatest Filament Winding News And Updates

Filament winding software focuses on efficiency, precision

JEC World 2024: Roth Composite Machinery is co-exhibiting with partner mefex GmbH to present new developments to its µRoWin software for automated filament winding.

Read MoreNCC commissions Cygnet Texkimp filament winder for hydrogen development

Multifunctional four-axis winding system offering fiber flexibility will underpin the NCC’s work in testing and manufacturing pressure vessels leading to commercial production.

WatchCompoTech promotes automated filament winding machine options

Custom-built, turnkey automated winding and filament placement equipment create new possibilities for manufacturers to cost-effectively produce high-strength structural carbon fiber components.

Read MoreMikrosam filament production line supports Amargo tank production

Mikrosam system features will support the production of Amargo’s chemically resistant pressure vessels or hydrogen storage in industrial plants.

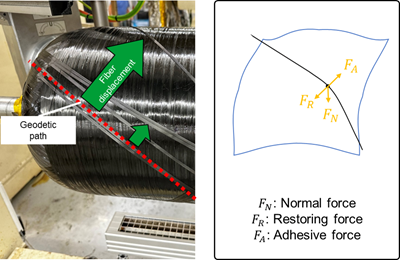

Read MoreIVW research to better determines fiber friction coefficient

Highly variable system development contributes to the increasing precision and efficiency in the manufacture of filament-wound composite components.

Read MoreAddcomposites highlights novel composites manufacturing developments

AFP-XS and AddPath updates, new AFP and continuous AM systems, upcoming webinars and blog content are available to interested industry members.

Read MoreFeatured Posts

Industrial equipment manufacturer expands global footprint, reaches into new markets

India-based CW Top Shops honoree EPP Composites reflects on a recently successful vertical filament winding application and new pultruded FRP rebar capabilities, as well as future opportunities.

WatchFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

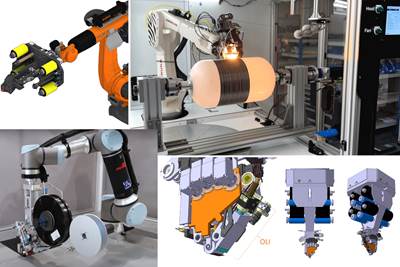

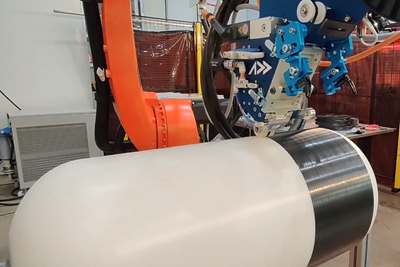

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreManufacturing tech for scalable Type V hydrogen tank fabrication, CFRP lifecycle management

Cygnet Texkimp’s Multi Roll Stack and composite recycling technology catalyze ASCEND program’s mission to optimize aerospace, automotive hydrogen storage and CFRP sustainability.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read More

.jpg;maxWidth=300;quality=90)