RTM

Bucci Composites completes testing of new carbon fiber wheel

Bucci’s new 22-inch high-performance automotive wheel is all carbon fiber and made via high-pressure resin transfer molding.

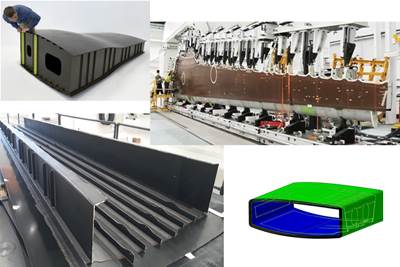

Read MoreThe path to OOA wings with minimal fasteners

A review of the quest to eliminate both the autoclave and mechanical fasteners in composite wing structures.

WatchHP-RTM as a means to reduce hydrogen tank packaging space and cost

BBG Gmbh & Co. KG has developed molds for producers of type IV CFRP tanks, integrating automation and sensors for faster, cheaper production of adjustable-length hydrogen storage cylinders.

Read MoreCollins Aerospace invests in braiding technology, secures funding for next-gen components

The multi-axis composite braider will be used to prove out production for complex-shaped components like pressure vessels, battery enclosures and more.

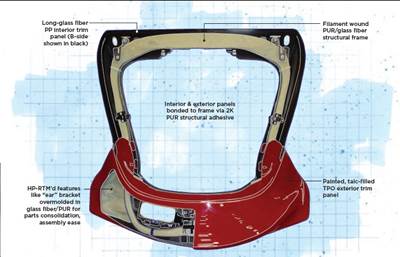

Read MoreLiftgate design puts modified filament winding to the test

Heavily modified winding process produces light, structural support frame for performance-critical liftgate.

Read MoreCarbon fiber automotive parts production industrialized via C-RTM process

Compression resin transfer molding overcame the difficulty in shaping CFRP car parts with development time reduced by 50%.

Read MoreCSP fine-tunes CF-RTM process, launches production programs

The carbon fiber RTM press will be installed at the CSP facility in Palmela, Portugal in order to run the company's first commercial applications using this technology.

Read MoreNext-generation composites materials and processes explored

A supplement with the November 2020 issue of CompositesWorld takes a close look at some of the technologies that are driving innovation in the composites industry.

Read MoreComposites Academy launches online training with hands-on exercises

Composites Expert and Institut de Soudure partner to provide interactive advanced composites training to students and professionals worldwide.

WatchBBG presents self-closing HP-RTM molds for CFRP compact hydrogen tank production

The autonomous concept, sufficient for series production, enables lower investment costs. Up to 15 cylinders can be produced simultaneously per operation.

Read More

.jpg;maxWidth=300;quality=90)