RTM

TNL Applied Composites Manufacturing course begins February 2023

Hybrid, seven-session class helps participants learn the tricks of different composites manufacturing technologies from wet layup to pultrusion.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreToray jointly wins Infrastructure Maintenance award for steel pipe repair innovation

Together with Tokyo Electric Power Grid and Yasuda Seisakusho, Toray employed in-situ VARTM with carbon fiber sheets to repair steel pipe corrosion on transmission towers, with application extension underway.

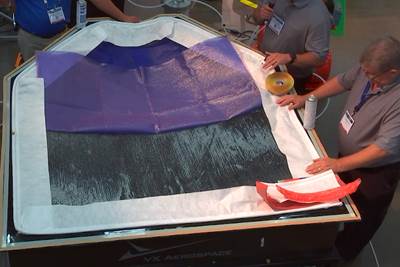

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

WatchsensXPERT Digital Mold earns 2022 AVK Innovation Award

Data-driven sensor technology optimizes and increases composites manufacturing efficiencies in real time, achieved through collaborative network.

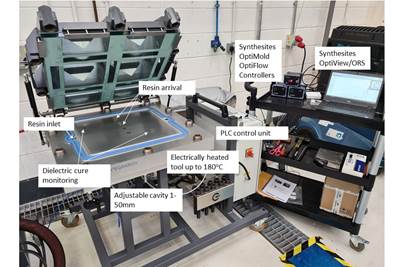

Read MoreUlster University, Synthesites advance intelligent cure monitoring

Research collaboration to enable active control and optimization for RTM process for composite structures manufacture.

Read MoreDow Chemical, MVP introduce polyurethane-enabled LRTM process

Transportation industry solution decreases LRTM injection times using specialized three-component material chemistry and fully automated injection unit with Fast Flow LRTM process.

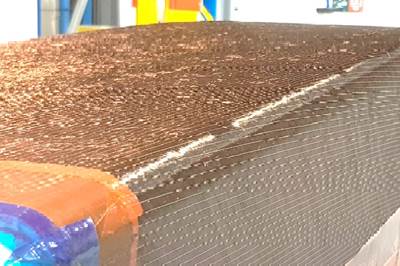

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreDigital Demo: Aerospace Carbon Fiber Infusion

Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

WatchBucci Composites presents 20-inch carbon fiber rim dedicated to the aftermarket

The elegant, sporty composite rim design manufactured via HP-RTM targets weight reduction, with key features addressing ease of assembly and high-temperature conditions.

Read More