Curing

GMI Aero extends Anita EZ hot bonder thermocouple capabilities

Thirty-six thermocouples (T/Cs) are now available for flexible temperature monitoring/control during composite curing.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

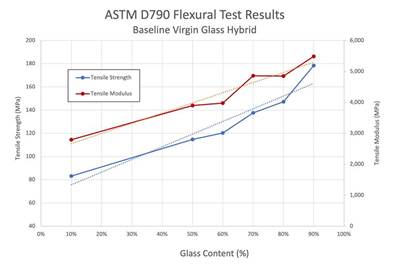

Read MorePilot program turns EOL wind blades to liners for pipe infrastructure

TPI Composites, Tex-Tech and Carbon Rivers partner to process wind blades, pyrolyze the material and use the recovered glass fibers to give new life to damaged existing pipelines.

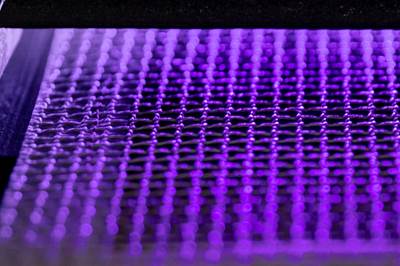

Read MoreEUVAM project investigates energy-efficient UV process for composites curing

University of Stuttgart researchers intend to develop flexible, highly productive and digitally controllable manufacturing approach for small urban vehicle production.

Read MoreDLR completes MFFD upper shell skin layup

Eight-meter-long CFRTP fuselage skin was achieved via laser-heated in-situ consolidation, with stringers, frames and cleats to be welded.

Read MoreArkema, CNRS open France-based lab for UV-curable material exploration

Accelerated photopolymerization research to benefit adhesives, 3D printing, composites, electronics and coatings applications, among others.

Read MoreChantiers de l’Atlantique reveals 66-meter, all-composite SolidSail mast

A technological feat, the large carbon fiber mast prototype targets the Silenseas sailing liner and sailing cargo ships for up to 40% reduction in CO2 emissions.

Read MoresensXPERT Digital Mold earns 2022 AVK Innovation Award

Data-driven sensor technology optimizes and increases composites manufacturing efficiencies in real time, achieved through collaborative network.

Read MoreMikrosam, H2Storage collaborate on 300+-liter Type IV hydrogen tanks

Automated filament winding cell achieving wind speeds of 6 meters/second improves production performance, shortens curing cycle for serial production of 700-bar Type IV tanks.

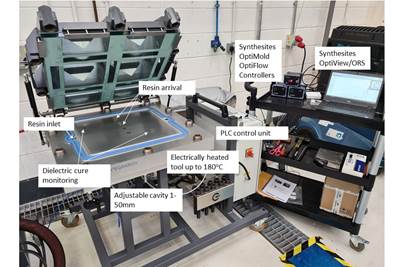

Read MoreUlster University, Synthesites advance intelligent cure monitoring

Research collaboration to enable active control and optimization for RTM process for composite structures manufacture.

Read More