The Gill Corp. announces new Gillfab 4037 sandwich panel

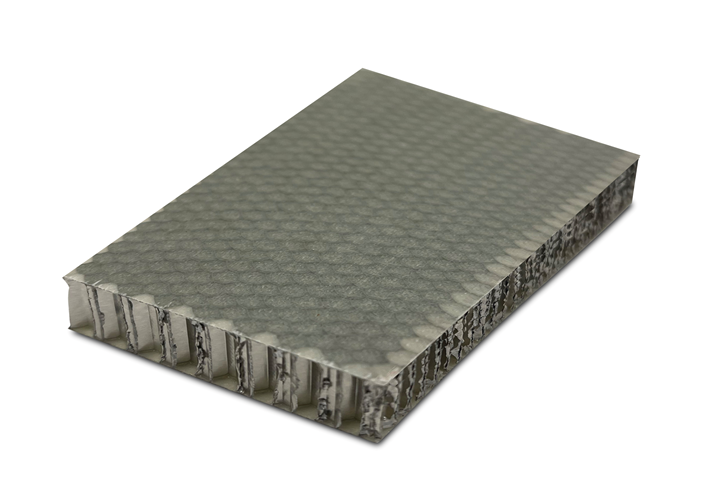

Fiberglass-reinforced epoxy panel with aluminum honeycomb core meets corrosion and flame resistance specifications for use in nonstructural aircraft interiors.

The Gill Corp. (El Monte, Calif., U.S.) presents the Gillfab 4037 sandwich panel which is made of 7581 fiberglass cloth reinforced epoxy laminate facings and Dura-Core II aluminum honeycomb core. This panel is designed for nonstructural interiors in business aircraft.

Constructed with lightweight and high-strength materials, Gillfab 4037 exhibits good corrosion resistance. It also has good self-extinguishing characteristics, meeting the specification of the FAR Part 25.853 60-second vertical flammability test to ensure the safety of passengers and crew members.

On average, the panels comes in sizes of 2,438 × 1,219 mm and up to a maximum of 3,568 × 1,727 mm. Additional specifications regarding thicknesses and performance properties can be viewed here.

The Gill Corp. is a manufacturer of high-performance composite materials and products for aerospace, transportation and other industries. The company has extensive vertically integrated capabilities that include fabrication, assembly and kitting. Parts can be delivered that are ready for installation.

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Composite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.