Teijin unveils novel spread-tow carbon fiber woven fabric

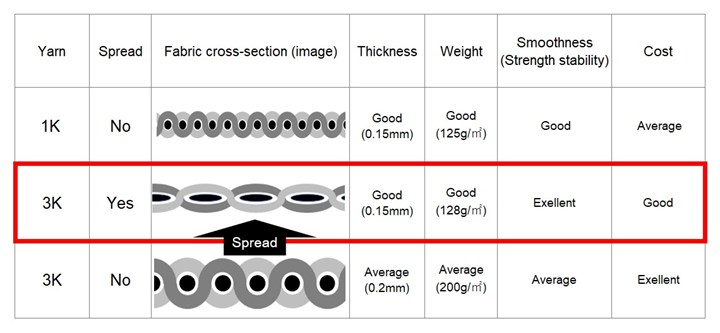

3K woven fabric developed via Teijin’s tow-spreading technology is as thin as 1K wovens and nearly the same weight, but is said to require less cost to produce, and offers better strength stability.

Photo Credit: Teijin Ltd.

Teijin (Tokyo, Japan) has launched a lightweight, strong and cost-effective carbon fiber woven fabric developed with the company’s proprietary tow-spreading technology.

The new woven fabric is made with 3K (3,000) carbon fiber filament yarn for applications requiring low weight and design flexibility, such as automotive interior materials and sporting goods. Teijin, using its in-house tow-spreading technology, succeeded in thinning the 3K fabric from a molding thickness of 0.2 mm to approximately 0.15 mm, the same as that of 1K woven fabric, when molded into carbon fiber-reinforced plastic (CFRP).

Thanks to the flat undulations of the fabric’s intersecting yarns, CFRP made with Teijin’s new fabric is said to offer improved smoothness. This, according to Teijin’s in-house research, results in more stable strength compared to CFRP made with 1K carbon fiber woven fabric. In addition, the company says its proprietary tow-spreading technology lowers the fabric cost below that of conventional 1K woven fabric, and, despite using 3K yarn (200g/m2), Teijin reduced the weight by 35%, similar to fabric made with 1K yarn (125g/m2).

Teijin plans to market the woven fabric to manufacturers of industrial and sports products. Together, with the other spread-tow carbon fiber woven fabrics in the Teijin portfolio, the company is targeting sales of JPY 2 billion (approx. $17.4 million) in fiscal 2030.

Related Content

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

CAMX 2022 exhibit preview: Bally Ribbon Mills

Bally Ribbon Mills’ highlights its capabilities in design and manufacture of woven structural shapes for hybrid composite structures used in aerospace applications.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.