PRF Composite Materials releases RP542-4 toughened prepreg system for UD and woven fabrics

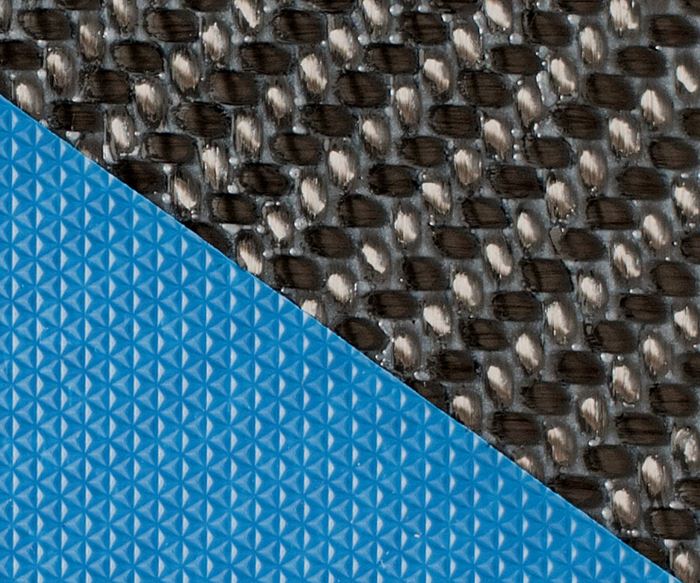

PRF Composite Materials’ RP542-4 is its latest epoxy prepreg system for unidirectional and woven carbon fiber fabrics.

PRF Composite Materials (Dorset, U.K.) introduces RP542-4, its latest epoxy

prepreg system for unidirectional (UD) and woven carbon fiber fabrics. RP542-4 has been designed as an intermediately toughened system to complement the company’s RP542-1 and super-toughened RP549 systems.

According to the company, the system has exhibited excellent tensile, compressive, flexural and interlaminar properties through mechanical testing, and has shown a coefficient of thermal expansion (Tg) of 138°C after curing at 120°C. The onset Tg can reportedly be improved by 20°C to 120°C after postcuring at 140°C for 2 hours. The system has an outlife of 60 days at 20°C. RP542-4 is available on 300-gsm and 600-gsm unidirectional carbon fiber as well as on a variety of fiber types in PRF’s range of high-quality woven fabrics.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

-

Plant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

.jpg;width=70;height=70;mode=crop)