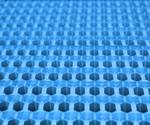

EconCore thermoplastic honeycomb panel production technology

EconCore’s ThermHex honeycomb technology converts thermoplastics to high-performance, lightweight honeycomb core structures and, combined with inline lamination of skins, produces lightweight sandwich panels.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

New polymer expands composites options in demanding environments

Aromatic thermosetting copolyester offers unique properties, availability in multiple form factors.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

.jpg;width=70;height=70;mode=crop)