CAMX 2021 exhibit preview: Cygnet Texkimp

Cygnet Texkimp hopes to accelerate the use of composites in hydrogen technology with its new Filament Winding Innovation Hub, which will enable customers to explore every aspect of the filament winding process.

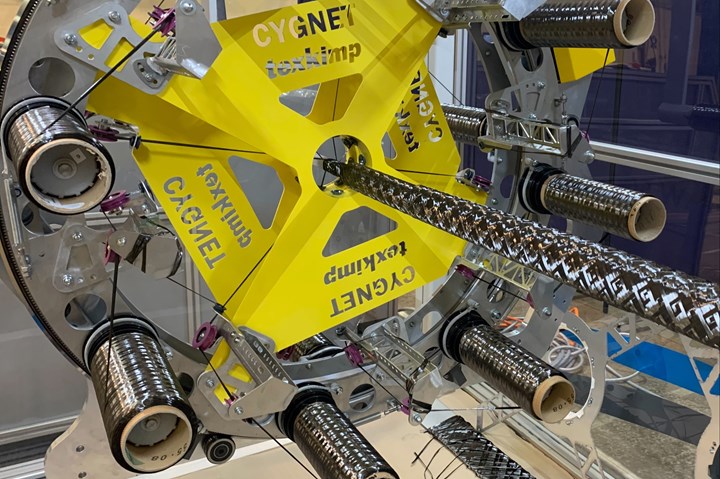

Cygnet Texkimp's filament winding technology. All photo credit: Cygnet Texkimp

Fiber converting specialist and custom machinery manufacturer Cygnet Texkimp (Wincham, Northwich, U.K.) showcases the launch of its Filament Winding Innovation Hub, designed to accelerate the use of composites in hydrogen technology.

It is the first phase of development in the company’s Composites Demonstration Center, which will eventually house production-scale examples of all of its processing technologies. The company hopes the new facility will allow customers to explore every aspect of the filament winding process, evaluate materials, optimize process design and complete the initial validation stage through collaborative development.

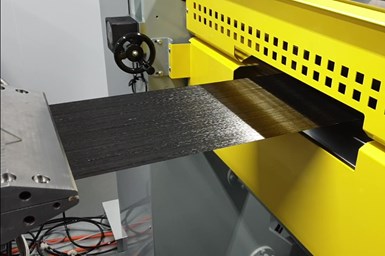

Cygnet Texkimp's thermoplastic technology.

Cygnet Texkimp’s standard, multi-axis and 3D-winding machines will be available for secure customer trials alongside its thermoplastic and thermoset prepreg processing lines and high-tension slitting and spooling technology. The company’s thermoplastic line is designed to produce high-grade thermoplastic prepregs using standard polymers as a cleaner, greener and more recyclable alternative to thermoset technology.

Gareth Davies, Cygnet Texkimp international sales manager, emphasizes the importance filament-wound composites bring for the evolution of the hydrogen economy, including the manufacture of pressure vessels to store and transport hydrogen used in global land, sea and air applications. Cygnet Texkimp, Davies says, is effectively shortening the process development stage for companies that want to try out something novel while reducing the risk around investment in large-scale capital equipment.

Cygnet Texkimp's slitting technology.

Further, in February 2022, a high-tension slitter spooler will complete the filament winding hub. This will be capable of processing UD prepreg slit tapes and offer a solution for high-end filament-wound applications most relevant to the space, aerospace and defense markets

Related Content

-

Plant tour: Renegade Materials Corp., Miamisburg, Ohio, U.S.

Renegade Materials is known for high-performance prepregs for aerospace applications. Following its acquisition by Teijin in 2019, the company has expanded capacity and R&D efforts on a range of aerospace-targeted materials.

-

Measuring ply-wise deformation during consolidation using embedded sensors

Strip-type shape sensor method claims real-time measurement of ply-wise deformation.

-

High-performance sustainability and cost-efficiency advance with HiPerDiF

In the latest chapter of the HiPerDiF (High Performance Discontinuous Fibre) story, commercial production is on the near horizon for high-performance composite materials that are both sustainable and formable, leading to simpler, more cost-efficient composites manufacturing.