Solico, Rondal collaborate on an all-composite halyard winch

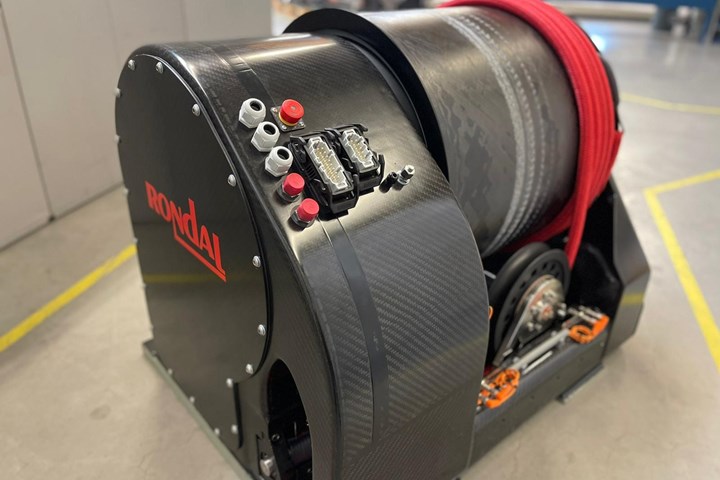

The winch is comprised of a carbon fiber prepreg winch housing and filament-wound carbon fiber winch drum which contributes to stability improvements and overall efficiency in marine applications.

Photo Credit: Solico Engineering, Rondal

Solico Engineering (Dubai, United Arab Emirates), a maritime composite engineering specialist, has collaborated with composite spar and component builder Rondal (Vollenhove, Netherlands) on a wide variety of engineering projects, including its most recent all-composite halyard winch.

The composite winch was designed for a nominal load of 18,000 kilograms (approx. 39,683 pounds), with three different sizes engineered by Solico. The company also completed finite element analysis (FEA), structural verification and laminate specifications for the carbon fiber prepreg winch housing and filament-wound carbon fiber winch drum. According to Solico, weight reduction in these highly loaded winch systems improves the overall efficiency of the sail handling package as well as contributing to stability improvements and allowing additional equipment to be carried onboard.

Solico is exhibiting at METS 2021, a trade exhibition of marine equipment, materials and systems, in Amsterdam from Nov. 16-18, 2021. The Solico stand will highlight the company’s full spectrum of composite engineering capabilities, focusing on sailing superyachts, motor superyachts, commercial marine craft and small boats. Also on display will be two of Solico’s most recent projects, the all-carbon fiber captive reel winch from Rondal, and a scale model of the new 30-foot Aeolos P30 carbon fiber race boat.

Related Content

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

One-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.