Cevotec fiber patch placement improves storage efficiency of composite tanks

Cevotec’s solution is to apply carbon fiber patches to the dome areas of Type IV pressure vessels, which reportedly yields 15% in material, weight and cost savings.

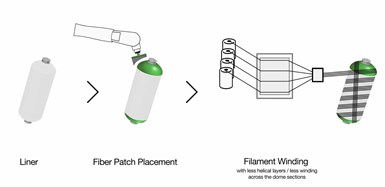

Cevotec fiber patch placement process for composite tanks. All photo credit: Cevotec

Cevotec (Unterhaching, Germany) reports that it has developed an industrial solution to improve the storage efficiency of Type IV composite tanks in hydrogen-powered electric vehicles (EVs), reducing the amount of carbon fibers consumed by up to 15% while maintaining equivalent mechanical properties.

Cevotec’s solution is to apply carbon fiber patches in the tank’s dome areas, thereby replacing the high-angle helical layers (HAHL) in a typical filament winding pattern. Reinforcing a tank’s dome area with its fiber patch placement (FPP) technology reportedly yields 15% in material, weight and cost savings, and shortens total manufacturing time by 20%. By using FPP dome reinforcements, Cevotec says that manufacturers need less material in the subsequent filament winding process.

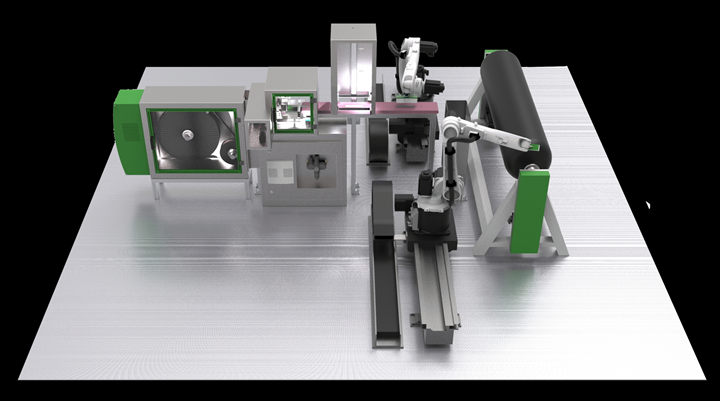

Cevotec’s fully automated, quality-controlled SAMBA FPP system first places the reinforcing fiber patches at the dome area directly on a standard liner. Then the patched liners are transferred over to the filament winding process; SAMBA requires no additional post-processing. The winding process is then adjusted to leave out the HAHL layers, for a faster, less material-intensive process, increasing overall line capacity for tanks, which further improves ROI and production economics

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Troubleshooting thermal design of composite battery enclosures

Materials, electrical insulation and certification are all important factors to consider when optimizing electric battery performance against potential thermal runaway.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.