Airborne introduces Automated Ply Placement technology at JEC World 2022

Automated, accurate and fully integrated preforming process maximizes design freedom of composite laminates, expands material options.

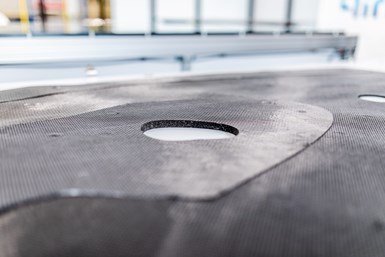

At the JEC World 2022, Airborne (The Hague, Netherlands) is premiering its Automated Ply Placement technology, which the company says can make multi-material, free-shape and tailored laminates in an automated and user-friendly way compared to other composite automation technologies like automated tape laying or fiber placement (ATL/AFP). The Automated Ply Placement technology enables users to create optimal composite designs and benefit from full automation.

Converting composite material into tailored blank laminates or preforms is a crucial but vulnerable step of making composite parts, Airborne notes. It is either a manual and slow process, or an automated process with limitations in the materials that can be used or the shapes that can be made. Alternately, Airborne’s Automated Ply Placement technology ensures a designer can use all materials available on the market (the process can implement prepreg, dry fiber or thermoplastics), create an optimal, high-accuracy laminate with freeform edges and patches or cut-outs and design for optimal performance.

Unidirectional (UD) tapes, textiles (fabrics, non-crimp fabrics), film, core materials, recycled materials, metal layers and more can be used with this process. Airborne says it is able to handle materials on roll as well as sheet materials. Sandwich laminates are also possible. The system cuts the materials into the right ply shapes, stores it in the buffer station and creates the laminate with robotic ply placement which fully inspects and accurately places plies and spot-welds to stabilize the laminate. Final laminates are reported to be 100% net shape with no trimming required. Moreover, Airborne’s Automated Programming software makes the technology more user friendly; the design, material and operational input is automatically translated to the right machine code and process settings on-the-fly and on the shop floor.

There are multiple benefits to this technology for the user, Airborne says. First is a fully automated and integration layup process on one system (cutting inspection, placement and storage of plies and finished laminates). Secondly, laminate designs can be created that are not feasible, or are difficult to manufacture with other technologies. Third, Airborne has made it so the system is ready to use future materials that are coming to the market, such as recycled materials, bio-based materials or novel material forms that can not be processed with, for example, fiber placement. Since it is a robotic system, the downstream processes such as press/hot-drape forming, trimming, inspection or placement into the mold can also be easily integrated.

“Automated Ply Placement opens up many new possibilities for automation and laminate designs,” Marcus Kremers, CTO of Airborne, emphasizes. “In composites, there are, of course, many materials to choose from and almost all of them come as wide rolls. With other automation technologies, those need to be slit, which is expensive and limits the availability of materials. The ability to automated manufacturing then comes with a limitation in materials and we have aimed to solve that. The system we developed can work with all composite materials to provide the designer maximum freedom.”

Related Content

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreModular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreRUAG rebrands as Beyond Gravity, boosts CFRP satellite dispenser capacity

NEW smart factory in Linköping will double production and use sensors, data analytics for real-time quality control — CW talks with Holger Wentscher, Beyond Gravity’s head of launcher programs.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More