Stepping up to provide worker training and education

Two companies offer effective means to ensure skills transfer.

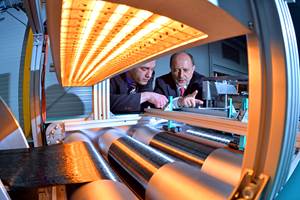

Stiles Education offers courses to anyone desiring knowledge of CNC machine control and maintenance. An instructor is shown here teaching a recent class.

Brett Chouinard of Altair Engineering Inc. speaks at the recent CW Carbon Fiber 2014 conference about composite design and getting the message out to design engineers about optimized design.

It seems that just as composites finally earn their way into a wide array of applications and industrial sectors, and growth seems certain, there’s a risk of a shortage of skilled workers. The U.S. economy, at least, seems to be on the road to recovery, and the composites industry in particular is growing, but can companies keep hiring and retaining enough talent to keep the boom going, particularly to replace retiring baby boomers with extensive skill sets?

CW has reported on many company initiatives, consortia, partnerships among colleges and universities, military veteran training programs, outreach to high schools, and more, that are aimed at providing the skills for manufacturing jobs. In one example, Airbus is working with local companies in the Mobile, AL, US area, and has built a training center adjacent to its fabrication plant there, to ensure a competent workforce. In Washington State in the US, several educational groups and consortia are working to increase worker training at local colleges that feed Boeing’s aircraft fabrication. Check out these published articles, among others, at compositesworld.com: http://www.compositesworld.com/articles/training-surge-too-little-too-late; http://www.compositesworld.com/columns/composites-education-improvement-through-collaboration). Recently I learned about two more interesting and focused solutions for workforce training.

“The manufacturing supplier base has evolved,” asserts Stephan Waltman, vice president of marketing and communications at Stiles Machinery Inc., Grand Rapids, MI, US. “To maintain viability, you now have to supply more than just materials and technology — you have to supply solutions to get the job done, and that includes education and training of people.” Stiles has certainly walked the walk. They established, in 1990, an in-house school to provide education to anyone who wants to learn about advanced CNC machines, not just Stiles customers.

Waltman says the idea came during a strategic planning meeting: “We realized that a deterrent to selling complex CNC machining centers over time would be a shortage of qualified maintenance people and operators. We felt we had to do something ourselves, and not sit back and hope that high schools around the country would add courses on machine logic.” With no qualified educators or instructors within the company, Stiles hired a well-known educator in the industry to head the school, called Stiles Education. This unique program has since been recognized by Michigan State University (MSU) as an educational provider, and has been accredited as an Authorized Provider by the International Association for Continuing Education and Training (IACET, McLean, VA, US) and complies with the ANSI/IACET standard of good practice.

More than 30,000 students have passed through the school, which includes courses on programming and machine language, maintenance of electrical and digital CNC controls, cutting processes, fixturing and advanced materials including composites. While primarily offering a fixed schedule of classes, Waltman says that customized courses can be created for any company, to teach a specific syllabus on, for instance, composite materials machining or drilling. He emphasizes that the courses are not related to selling Stiles equipment, but geared toward understanding the technologies employed in digital manufacturing.

“This is a long-term planning challenge,” adds Waltman. “We can all do a better job at solving this problem, by being more proactive today and working with our communities and trade associations, creating apprenticeships, and mobilizing resources to create the skills we need.”

Another Michigan company, Altair Engineering Inc. (Troy, MI, US), is taking the proactive approach to ensure its product is understood by engineers, which benefits both its business model and composites design. Brett Chouinard, chief operations officer, spoke recently at CompositesWorld’s Carbon Fiber 2014 conference in La Jolla, CA, US about recent projects, and Altair’s concept of Optimization Centers for clients.

“Our whole industry is filled with engineers who don’t know how to design,” declared Chouinard during his La Jolla presentation. Altair’s HyperWorks OptiStruct design software allows engineers to take existing structures and, based on physics and mathematical discipline, optimize the structures by taking out weight and unneeded material. He cited a project for Airbus, in which wing leading edge ribs were redesigned in 13 weeks by a team of Altair and Airbus engineers, resulting in a weight savings of 500 kg. Another project involved a wheel manufacturer who called in Altair in response to a competitor’s new product. With optimization, the Altair/customer team came up with an entirely new concept that ultimately put the competitor out of business, according to Chouinard.

He is passionate about educating customers in a “pervasive” design environment, and believes in interacting with design engineers through Optimization Centers, which are “skill centers of excellence” where optimization methods are practiced. “It’s a different way of thinking about design,” adds Chouinard, “and takes into account weight, cost, manufacturability and performance.” So far, Altair has set up 20 Centers at customer sites, including The Boeing Co. (Chicago, IL, US), to help train designers in optimization methods.

Related Content

Chemnitz University of Technology receives €6 million to expand research into "green" carbon fiber

Carbon LabFactory and InnoCarbEnergy project conduct R&D across entire value chain from raw materials through processes to structures and systems on a pilot line with technology demonstrators.

Read More9T Labs, Purdue University to advance composites use in structural aerospace applications

Partnership defines new standard of accessibility to produce 3D-printed structural composite parts as easily as metal alternatives via Additive Fusion Technology, workflow tools.

Read MoreUniversity of Maine unveils 100% bio-based 3D-printed home

BioHome3D, made of wood fibers and bioresins and entirely 3D printed, highlights Maine’s effort to address the need for more affordable housing.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)