Composites testing as part of a building block approach, Part 1: Coupon-level testing

The building block materials testing approach is a step-by-step process that serves as a framework for designing composite structures while also reducing risk and cost.

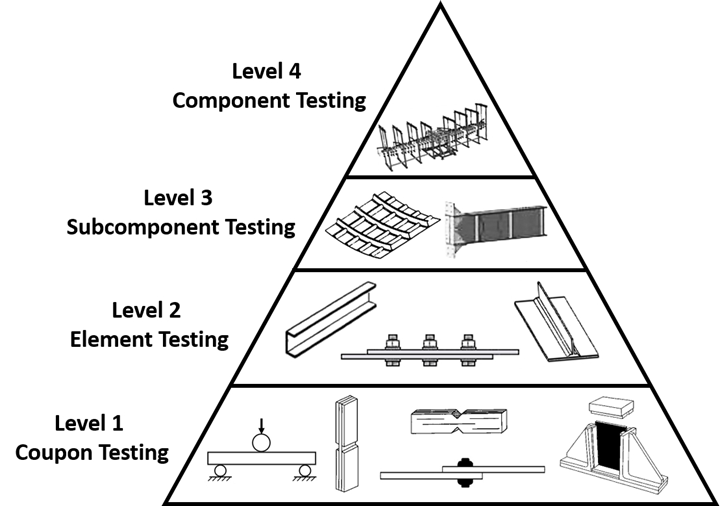

Fig. 1. Building block approach for composite structures. Photo Credit: Dan Adams

Within the context of composites testing, a building block approach is a step-by-step series of mechanical tests of increasing complexity, coupled with analyses performed at each step, that serves as a framework for designing composite structures. Although a majority of references to the building block approach for composites design focus on the aviation industry where it was first developed, the general approach is followed in many other end markets served by the composites industry. Not surprisingly, the amount and types of composites testing varies greatly, and is dependent on both the application and the complexity of the composite structure.

A general building block pyramid, illustrating the levels of testing performed, is shown in Fig. 1. In a building block approach, the levels or “blocks” each serve specific purposes and are addressed sequentially, starting from the bottom. Testing associated with each level may be described in terms of the complexity of the test articles as well as usage of the test results. In this column, I’ll focus on the lowest level of the building block pyramid that corresponds to the initial stages of the design process.

The base level of the building block pyramid, referred to as the coupon level, is where a majority of all coupon-level testing is performed. There are multiple purposes for these tests, which vary greatly depending on the structure being designed. The first purpose of testing is to screen candidate composite materials. Screening tests are performed to determine basic stiffness and strength properties of candidate materials, if they’re not already available.

Additionally, it’s common practice to select additional types of screening tests to obtain key properties for particular applications or purposes. For example, short beam shear tests (ASTM D 23441) are useful for material selection because the measured short beam strength is highly sensitive to problems with porosity, fiber-to-matrix adhesion and the layer-to-layer strength within a composite laminate. Additionally, open-hole compression testing (ASTM D64842) and compression-after-impact testing (ASTM D71373) are used in many aerospace applications, as both serve as screening tests for notch sensitivity and the former is used for notched laminate design allowables that are often more critical than compression strength. Since the specific multidirectional laminates to be used have not been selected, quasi-isotropic laminates (25% 0° layers, 50% ±45° layers and 25% 90° layers) are typically used for these tests. Additionally, these screening tests are sometimes performed at the critical environmental conditions expected for the application, such as at elevated temperature using moisture-conditioned specimens. Candidate composite materials may also be subjected to manufacturing and repair trials before making final selections.

While requiring considerable time and expense, such testing is intended to reduce the number of subcomponent and component level tests further up the pyramid.

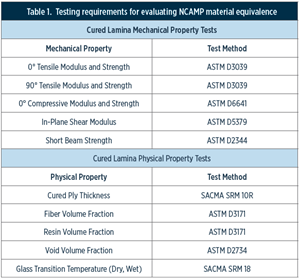

Note that a considerable portion of these screening tests could be eliminated if a composite material was selected for which an existing database exists. Although composite material suppliers typically provide only a limited set of properties for their materials, public databases are available for an increasing number of composite materials. For example, the Advanced General Aviation Transport Experiments’ (AGATE) database4, developed in the 1990s, includes lamina material properties for carbon fiber- and glass fiber-reinforced composites with woven fabric and unidirectional fibers. Additionally, the National Center for Advanced Materials Performance (NCAMP) database5 includes lamina and laminate property data for a variety of composite materials with a focus on the aerospace industry. Finally, mechanical property data for a variety of composite materials of general interest is available in Volume 2 of the Composite Materials Handbook (CMH-17)6.

Once a candidate composite material has been selected for a particular application and the key mechanical properties to support the design have been identified, it’s important to develop a stable manufacturing process for test panel fabrication that can continue up the building block to more complex test articles leading to the final structure. With the processing specifications developed, testing of key mechanical properties for the particular application may be performed for multiple production batches of the material and used to establish preliminary material allowables — material property values that are statistically derived from test data. To do so, it’s common to perform tests using materials produced in multiple production runs. Testing may also be performed to address the effects of non-ambient environments. For polymer matrix composites (PMC), the most common environments of concern are hot/wet conditions, at which the matrix material loses stiffness and strength, and cold temperatures, at which the matrix material loses ductility.

Additional coupon-level testing is performed at this point in the design process to obtain material properties that are significantly more difficult to produce using analyses. Examples include notch sensitivity (open-hole and filled hole) tests, bearing tests and damage tolerance (compression-after-impact) tests. These tests are typically performed using specific multidirectional composite laminates of interest for the particular application. To limit the amount of required testing, it’s common to reduce the number of laminates by limiting the number of fiber orientations — for example 0°, ±45° and 90° plies — and varying the percentage of each set of plies within the laminate. For aerospace applications, common laminate tests include a quasi-isotropic laminate (25% 0° layers, 50% ±45° layers, 25% 90° layers) as well as other “hard” laminates (40-50% 0° layers). “Soft” laminates (8-10% 0° layers) are sometimes tested as well. Even with a limited number of candidate laminates, the number of tests can quickly multiply.

In summary, a relatively large number of coupon-level tests are typically performed at the base level of the building block approach. While requiring considerable time and expense, such testing is intended to control material and process variability and reduce the number of subcomponent and component level tests further up the pyramid, thus permitting overall cost reductions while reducing risk. As I mentioned at the outset, however, there is considerable variability in the building block process among different end markets and for varying complexities of composite structures. Much of what has been written about the building block approach has focused on aerospace, particularly commercial aerospace. Currently, the most extensive coverage of the building block approach is provided in Volume 3, Chapter 4 of the Composite Materials Handbook (CMH-17)7.

In my next column in the December 2021 issue, testing performed in the higher levels of the building block process will be discussed.

References

1ASTM D2344/D2344M-16, “Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates,” ASTM International (W. Conshohocken, PA, US), 2016 (first issued in 1965).

2ASTM D6484/D6484M-20, “Open-Hole Compressive Strength of Polymer Matrix Composite Laminates,” ASTM International (W. Conshohocken, PA, US), 2020 (first issued in 1999).

3ASTM D7137/D7137M-17, “Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates,” ASTM International (W. Conshohocken, PA.), 2017 (originally published 2005).

4Advanced General Aviation Transport Experiments (AGATE) database, www.niar.wichita.edu/agate/

5National Center for Advanced Materials Performance (NCAMP) database, www.niar.wichita.edu/coe/ncamp.asp

6Composite Materials Handbook - 17 (CMH-17), Volume 2: Materials Properties, SAE International, Rev. H, 2018.

7Composite Materials Handbook - 17 (CMH-17), Volume 3: Materials Usage, Design, and Analysis, SAE International, Rev. G, 2012.

Related Content

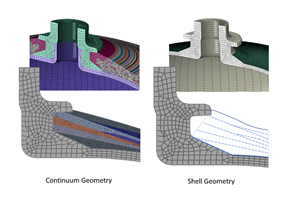

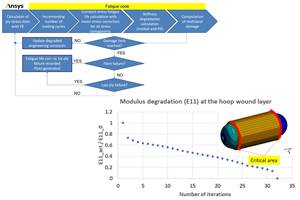

Improving analyses of composite pressure vessels

Accurate geometry modeling and equivalent material property approximations captured by WoundSim will play a role in improving COPV analyses.

Read MoreNumerical tool with mean stress correction demonstrated for fatigue life estimation of thermoplastic composites

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

Read MoreMaterial equivalence testing in shared composites databases

In response to traditionally proprietary polymer matrix composites (PMC) qualifications, NCAMP continues its efforts to make material property databases publicly available.

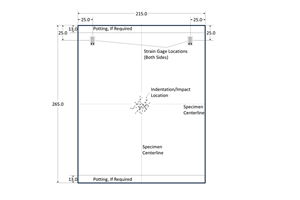

Read MoreDamage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Read MoreRead Next

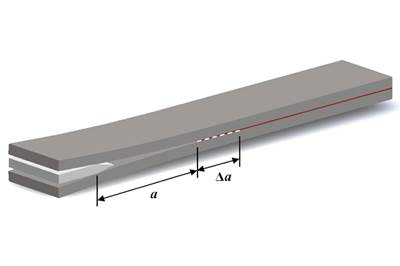

Durability testing of adhesively bonded composites

Current test method development shows potential for the composite wedge test, a standardized durability-based test for adhesively bonded composites.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;maxWidth=300;quality=90)