Latest Issue

April 2024

Digital Edition

In this Issue

Carbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

Read More

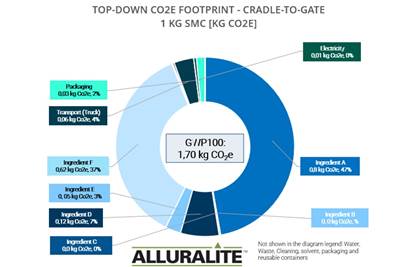

Life cycle assessment in the composites industry

As companies strive to meet zero-emissions goals, evaluating a product’s carbon footprint is vital. Life cycle assessment (LCA) is one tool composites industry OEMs and Tier suppliers are using to move toward sustainability targets.

Read More

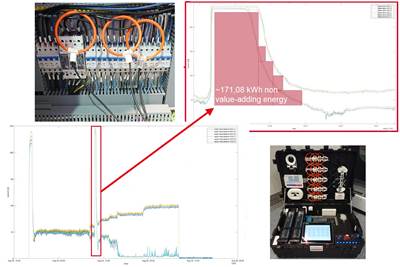

Measuring energy use to enable sustainable composites production

Airbus subsidiary CTC uses new technology to measure energy use in machine components and processes to optimize equipment, production lines and guide decisions for future composites.

Read More