Past, Present and Future

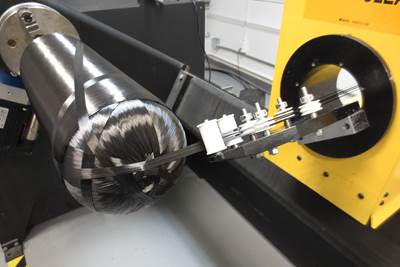

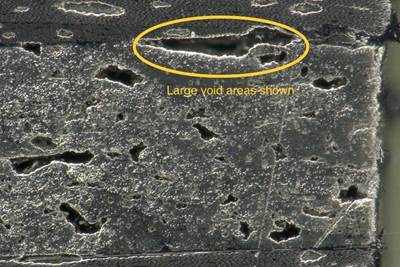

Best practices in the CNC machining of composites

Machining composite materials is a challenging task. Proper tool selection, machine settings and process innovations help make it manageable.

Read MoreValuable data: From travelers to the as-built digital twin

Taking advantage of the electronic record proves to be of significant value to composite fabricator’s record-keeping process.

Read MorePart 2: Performance and safety benefits of prepregs

Returning with his second installment, Brian Bishop discusses the performance and safety benefits to using prepreg, and the value they can bring to composites fabricators.

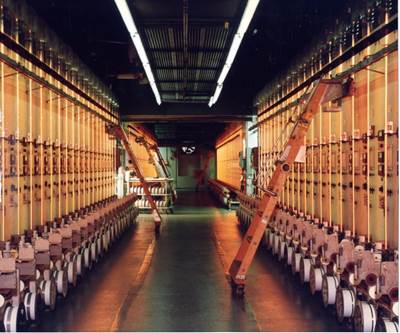

Read MoreRediscovering the benefits of prepregs in composites manufacturing

Compared to more traditional forms of composites manufacturing, prepregs enable reduced manufacturing costs and enhance production performance.

Read MoreBoron fiber: The original high-performance fiber

History and future developments for high-performance boron fiber.

Read MoreFiberglass composites improve infrastructure efficiency and sustainability

Gert de Roover, building, construction and infrastructure manager at Exel Composites, explains why composite materials contribute to the drive for greener buildings.

Read MoreDeveloping new solutions for noise, vibration and harshness

Several recent IACMI partner projects focus on technology innovation related to challenges in noise, vibration and harshness (NVH) in vehicle design.

Read MoreDeveloping new solutions to multimaterial joining

Several recent IACMI partner projects focus on technology innovation related to challenges in multimaterial joining for the wind and automotive sectors.

Read MoreEnabling a circular economy approach to advanced composites innovation, manufacturing and use, Part 2

IACMI chief technology officer Uday Vaidya reflects on IACMI’s role in improving composites’ recyclability and reusability.

Read MoreEnabling a circular economy approach to advanced composites innovation, manufacturing and use, Part 1

In part 1 of a two-month column, IACMI chief technology officer Uday Vaidya reflects on the organization’s efforts to reduce the embodied energy of composites.

Read More