Out of Autoclave

Moving forward on the Multifunctional Fuselage Demonstrator (MFFD)

Clean Sky 2’s MFFD program continues to move toward its goal of delivering a welded, thermoplastic composite fuselage demonstrator using next-generation manufacturing processes.

Read MoreEpisode 34: Carmelo Lo Faro, Solvay Composite Materials

Carmelo Lo Faro, president of Solvay Composite Materials, talks about how he sees aerocomposites evolving in the time of COVID-19, the rise of computational power to evolve composites use, the prospects for increased composites use in the automotive market, and the increasing importance of education in the composites industry.

ListenEpisode 33: Ethan Escowitz, Arris Composites

CW Talks checks in with Ethan Escowitz, co-founder and CEO of Arris Composites, to learn about the Additive Molding technology his company has developed.

ListenVictrex, Daher, attain next-gen thermoplastic aircraft panel milestone

The developed panel is a 176-ply laminate, 32-millimeter-thick composite structure and uses Victrex AE 250 PAEK-based thermoplastic composites.

Read MoreLight resin transfer molding

Magnum Venus Products introduces its new Fast Flow light resin transfer molding (LRTM) system, which offers reduced injection times, minimal waste, and minimal post-processing.

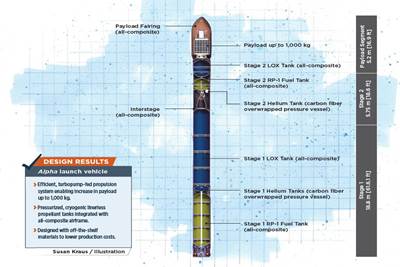

WatchThe Alpha launch vehicle: Designing performance in, cost out

Firefly Aerospace’s Alpha 2.0 launch vehicle, designed to deliver satellites into low Earth orbit, gets a composites makeover in pursuit of larger payload capacity and more cost-effective performance.

Read MoreAutomated aerocomposites production: Liquid molding or welded thermoplastic?

Two materials and process approaches are demonstrated for CFRP bulkhead production.

Read MoreMold cleaners, primers, sealers and internal/external releases

AXEL Plastics reviews its line of mold cleaners, primers, sealers and internal and external mold releases designed for closed mold and pultrusion manufacturing processes.

WatchNikkiso, Airbus partner for UltraFan demonstrator project

The project aims to provide nacelle components for the engine UltraFan demonstrator. Nikkiso’s role is to reduce manufacturing costs by a new out-of-autoclave curing method.

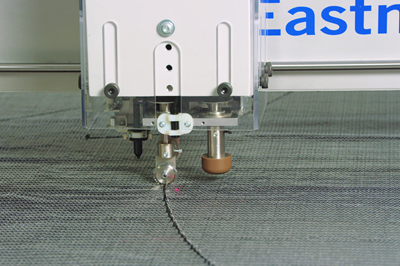

Read MoreAutomated Cutting of Composites Reinforcement Saves Time and Material, Improves Quality

Automated cutting of reinforcement materials is fast, accurate and reliable. It reduces labor costs and material waste and can substantially boost throughput.

Watch

.jpg;maxWidth=300;quality=90)