Effman installs AFP-XS as part of project to enable AFP for SMEs

uCOMP project with Addcomposites and Quebec partners demonstrates new woven tape and high-permeability preforms for resin infusion in <2 minutes.

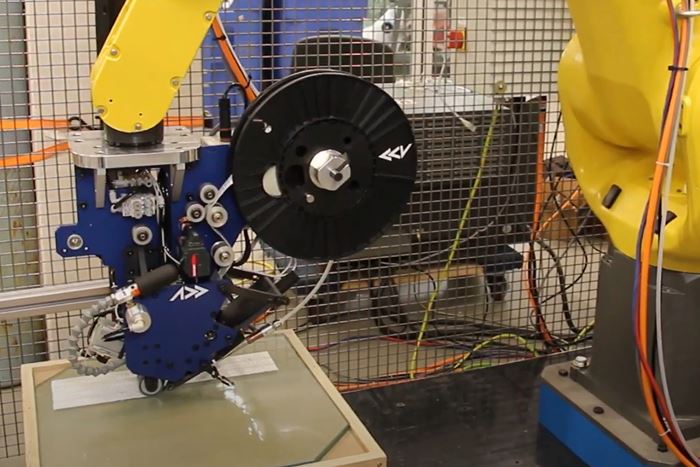

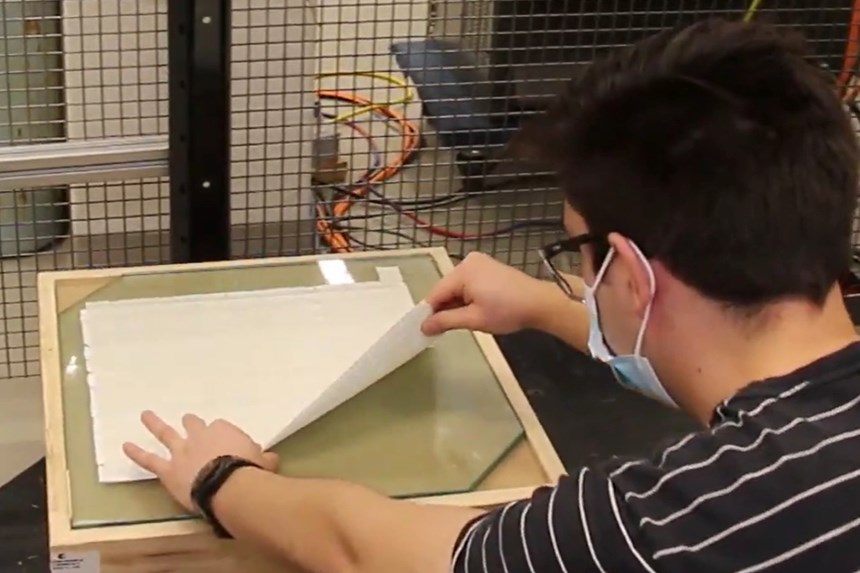

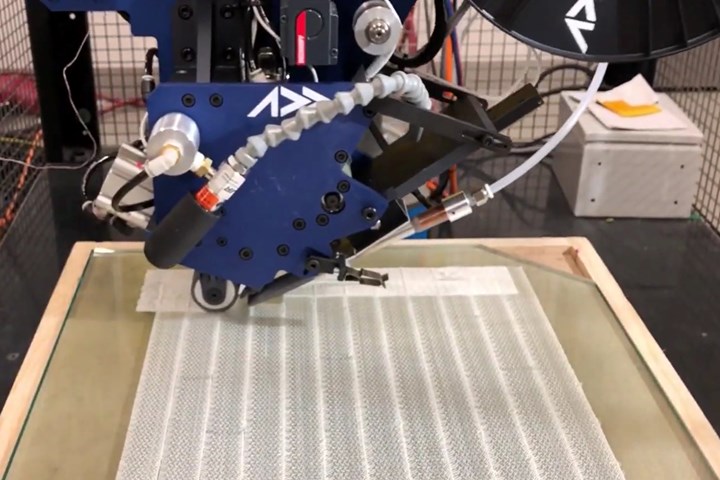

Effman installs Addcomposites AFP-XS onto FANUC robot. Photo Credit: Effman.

Effman (Sherbrooke, Quebec, Canada) has integrated and tested the first AFP cell in North America formed by plugging an Addcomposites (Espoo, Finland) AFP head into a FANUC robot. “Until now, AFP has been reserved for major players in the aerospace industries because of the complexity and cost of equipment,” says Yoann Bonnefon, president of Effman. Specializing in the development of automation for composites manufacturing, Effman is now collaborating with Addcomposites to make AFP robotic cells accessible to small and medium enterprises (SMEs).

“The uCOMP project started with the idea of bringing more automation to composites processes,” says Bonnefon. “We see that small companies especially are still relying on manual methods. We want to help them be prepared for the type of industrialization needed in today’s supply chains.” One goal is the ability to produce preforms for processes like vacuum infusion, resin transfer molding (RTM) and Light RTM. “We can improve the process and economics for such preforms,” says Bonnefon.

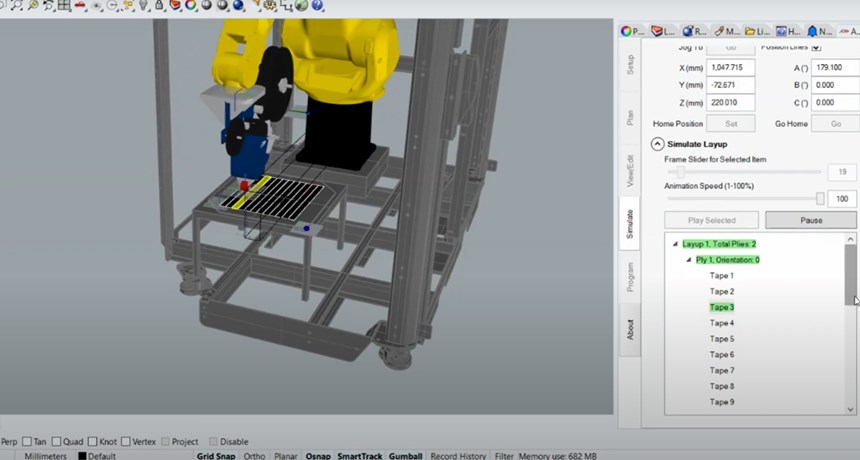

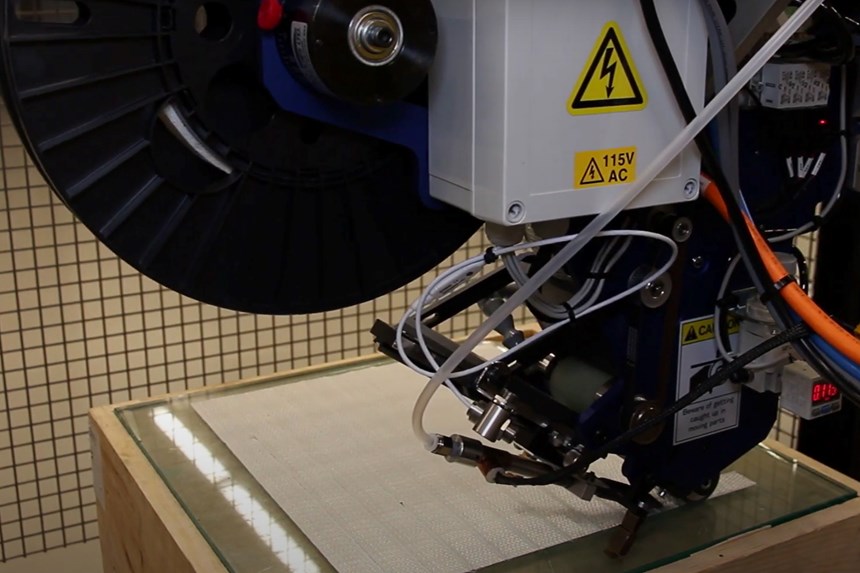

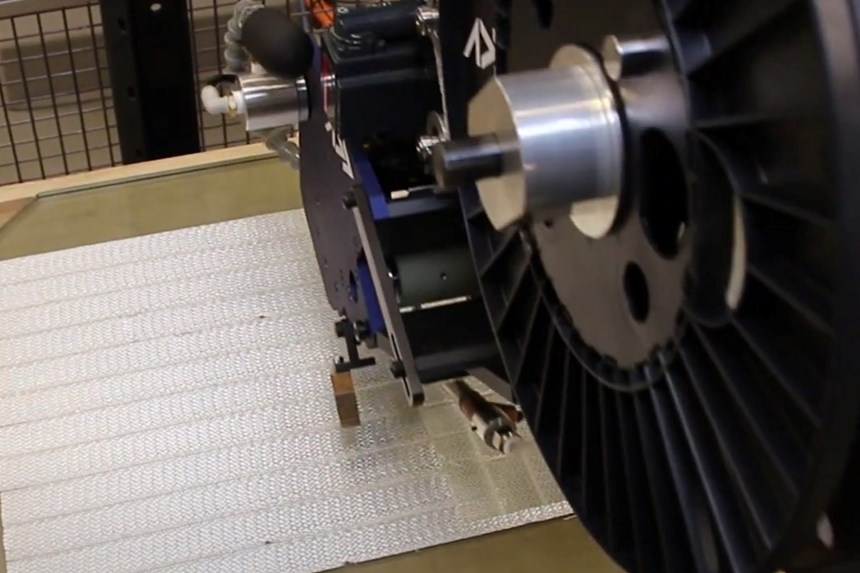

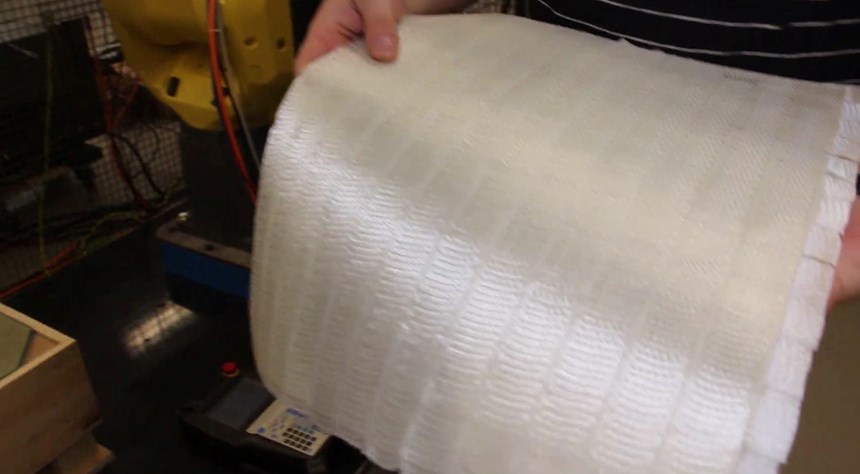

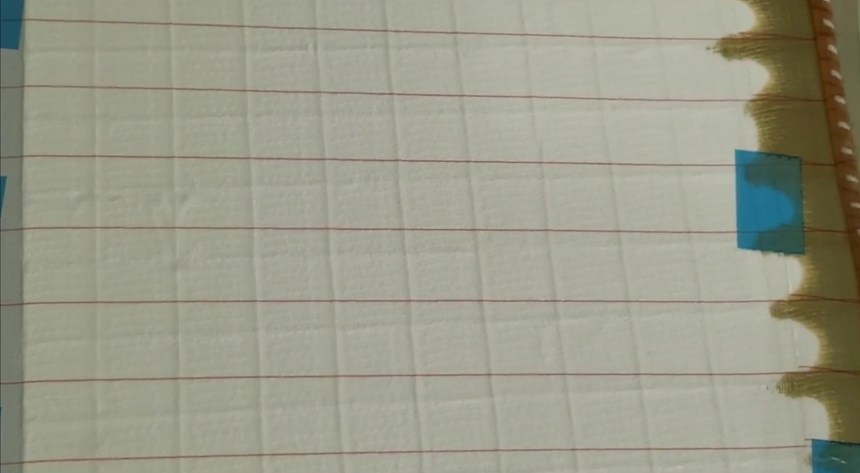

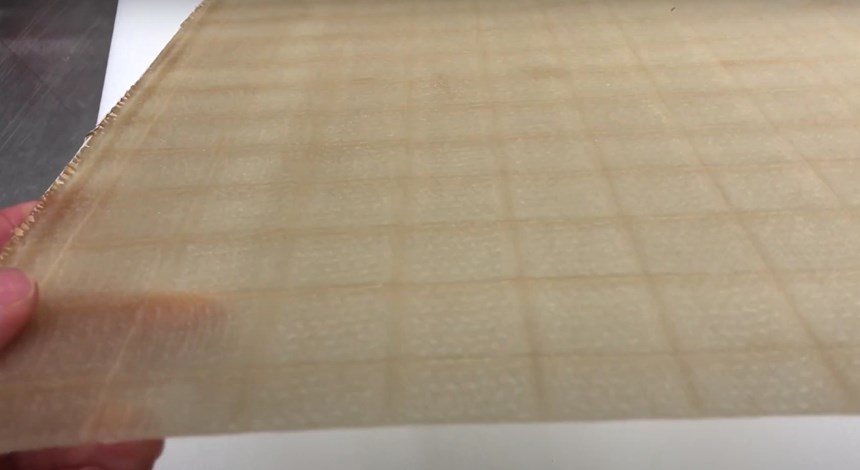

The AFP-XS provides the key for a light and compact robotic equipment solution that is affordable for small companies with limited financial resources. “This solution also needs to be simple,” adds Bonnefon, “able to be quickly installed and in operation without a lot of expense and training. The AFP-XS has met these needs, weighing less than 20 kilograms and fitting easily within a standard robotic cell. Without any experience with either the AFP-XS head or the ADD PATH software, we were able to complete the installation and, within a few weeks, complete the AFP simulation for parts using a new tape that we developed with a partner in Quebec. This woven glass fiber tape had never before been tested on an AFP-XS head, and yet we were able to use it and make preforms in less than two minutes that were easily processed using resin infusion.”

manufacturing and infusion of preforms

The uCOMP project aims to help SMEs use AFP. This technological advance is being achieved with Effman’s network of Quebec-based partners: CTT Group, Centre de développement des composites du Québec (CDCQ), FANUC America Corp., Armtex Fibres Inc. and Robox. “Our aim is to democratize the use of AFP and composites to make high-performance, affordable small- and medium-size parts,” says Bonnefon.

In addition to thermoset and thermoplastic tapes already used with the AFP-XS, Effman and its partners have developed dry-weave tapes (glass or carbon fiber) allowing the realization of preforms optimized for infusion and injection processes. Effman is now exploring projects with research organizations, to create new structures and new knowledge, but also sees opportunities in the supply chains for sporting goods, as well as automotive and aerospace, as the trends in electrification and new mobility advance. “This equipment is much cheaper than what currently exists in the market, yet enables precise fiber placement to make structural parts,” says Bonnefon. “We see many applications and look forward to working with companies across North America.”

Interested companies can contact Yoann Bonnefon and James Kuligoski for more details on part and equipment trials.

Related Content

Plant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCollins Aerospace demonstrates new thermoplastic composites capabilities

Collins Aerospace in Almere has produced a 7-meter raceway for the Clean Sky 2 MFFD lower fuselage using novel CCM and tooling technology while the Riverside facility in the U.S. advances AFP and welding as part of global strategy for more sustainable airframes.

Read MoreCFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

Read MoreRead Next

Addcomposites and Effman partner to provide AFP cells for SMEs

Aim is affordable, enclosed composites manufacturing cells for many different processes (AFP, grinding, buffing, sanding, drilling) in North American market.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More