Composite underground storage tanks protect national recreation area

Composite underground storage tanks for a service station in Ecuador, aided by AOC’s material technologies, are playing a role in protecting the natural environment of Playas Villamil National Recreation Area.

Composite underground storage tanks for a service station in Ecuador help protect the natural environment of Playas Villamil National Recreation Area, a preserve that includes 8.7 miles of beach. Tank Tech (Cundinamarca, Colombia) manufactured the tanks with composite technical support and corrosion-resistant Vipel resin technology from AOC Resins (Collierville, Tenn., U.S.).

The project in Playas, Guayas, specified three cylindrical tanks that were 11.26 meters long and 2.44 meters in circumference. Each vessel has a 45,425 liter capacity — two for storing gasoline, one for a gasoline-alcohol fuel blend. The higher strength-to-weight ratio of composites versus steel made it easier to transport the composite tanks over the more than 1,000-mile route between manufacturing and installation locations. The lighter weight products were also easier to install than steel alternatives.

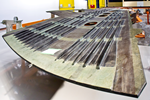

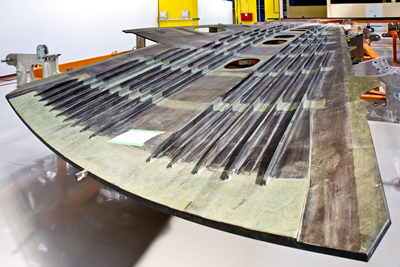

To achieve these tanks, Tank Tech sprayed resin-impregnated chopped glass fibers onto a rotating mold to form a semi-cylindrical tank section. The spray-up stream has a high 70-to-30 resin-to-glass ratio to promote maximum protection against the storage medium. The sprayed composite is applied as two separate wallsections that integrally encapsulate a special 3D fabric that creates an annular space. For public safety and environmental protection, the space is part of a system that monitors the tank 24/7 for potential leakage.

After the semi-cylindrical components cured, it was demolded and integrally joined with another half- section using hand layup of resin-impregnated fiber mat and woven roving. Essential to Tank Tech’s design engineering were trapezoidal cross-section ribs that technicians integrally encapsulated into the tank’s outer wall. The trapezoidal ribs provide monolithic structural reinforcement, maintain cylindrical geometry and resist forces acting on the tank.

The vessel’s profile is completed by integrating Tank Tech-designed hemispherical domes at each end of the completed cylinder. The end domes are molded using hand layup of resin-impregnated fabric and woven roving.

The performance of Vipel F798 high-crosslinked polyester played a major role in material selection. The project’s location near the beach raised concerns about potential corrosion from the salinity of the environment.

“For interior protection, the resin is certified under the UL1316 standard for underground storage of gasoline,” says Edward Alejandro Avendaño, production manager at Tank Tech. “This gives the customer peace of mind with the security of having a safe product.” Avendaño also pointed out the benefits of Vipel F798 resin’s lower styrene content and higher elongation properties than alternative resins. “The reduction in emissions and the characteristic odor is noticeable and appreciated by members of the production team,” he says. “The resin also gives laminates with greater hardness, which translates into better performance of the finished pieces.”

Before the tanks were covered and buried, Tank Tech’s composite construction was challenged by the area’s first heavy rains in months. During installation, the torrential rainfall flooded the excavation pit where the tanks were secured to ballast beams. The tanks became buoyant while being subjected to high hydraulic forces from rushing waters.

Nevertheless, a post-storm inspection showed no structural damage to the composite walls, and pneumatic testing verified that each tank’s composite construction maintained a hermetic seal. The tanks were buried to begin providing high performance and leak resistance under a 30-year limited warranty.

“Any surface that can come into contact with the hydrocarbon must be able to resist corrosive attack,” Avendaño says. “As a result, the entire tank is made of Vipel F798 resin. The material is also used to mold the access panel, reservoir, rings and explosive containment boxes. AOC technology and support helps us manufacture in a controlled and safe manner and deliver a product with the high performance our customers deserve.”

Read Next

Classic Citroën vans reimagined using composites, AOC resins

Caselani Srl, with support from AOC Resins and designer David Obendorfer, retrofits close to 400 vans/year to meet modern needs and comfort for Type H car enthusiasts.

Read MoreGlobal aerospace manufacture uses sensXPERT to shorten cycle times, meet increased rate and reduce waste

Using minimal sensors and one edge device, data from 20 production cycles was used to train machine learning models, accurately predicting outcomes in ≤50 minutes by forecasting when target degree of cure is reached.

Read MoreUMaine BioHome3D meets sustainability, strength and durability goals

Data collected from one year of outdoor testing reasserts the 3D-printed, bio-based structure’s viability to address housing challenges, sets the stage for future development.

Read More