BMW Leipzig: The epicenter of i3 production

A glimpse into the inner workings of an automaker at the forefront of serial-production autocomposites.

BMW’s i3, the first series-production car with a CFRP passenger cell, what BMW calls the Life Module, entered the European market in late 2013, and came to North America in spring 2014. Source: BMW AG

The composites industry is full of innovators and creative thinkers, people who move the industry forward incrementally toward greater efficiencies, lower costs and higher quality. But the big material and process leaps the composites community has seen throughout its history have required more than individual expertise. In the aerospace market, for example, The Boeing Co.’s 787 Dreamliner and the Airbus A350 are products of a massive, collective corporate commitment, backed by a capital investment as big, bold and precedent-setting as the envisioned product — a commitment that, to some composites pessimists, appears reckless, hasty, ill-timed and doomed.

Designed for city driving, the plug-in electric i3 can travel up to 100 miles/160 km on a charge. It also features a composite roof, reinforced with recycled carbon fiber, as well as convenient — and stylish — rear-hinged “coach doors.” Source: BMW AG

Corporate trailblazers are rare, and rarely attempt such leaps without a good command of the materials, processes and technologies required to achieve success. Even so, the risk of failure is real, and redoubles with the size of the enterprise. Missed deadlines and technical setbacks are all the more embarrassing to risk takers for being so public — and inevitably exploited by naysayers. But at the end of what is, at best, a colossal controlled experiment is the honor and recognition as the first to reach a bold and audacious goal.

Onto this less-traveled corporate road, Munich, Germany-based BMW Group steered when, in 2009, it elected to manufacture an all-electric, four-door passenger car using carbon fiber composites. Originally denoted the MegaCity Vehicle, the commuter car now known as the i3 is designed primarily for urban driving and can travel about 100 miles/160 km on a single charge. The i3 features two primary structures, the aluminum Drive Module — which incorporates the powertrain, chassis, battery, and structural and crash functions — and the Life Module (passenger cell), made from carbon fiber composites. The latter is capped by a composite roof made with recycled carbon fiber, and features a spare but comfortable interior that also incorporates recycled materials and other composites made with natural fiber reinforcements. Exterior body panels, hood and fenders are made with what BMW terms an “unreinforced” thermoplastic.

BMW Leipzig comprises 10 buildings, a test track, and four wind turbines that supply part of its electric power. In four of the 10 buildings, 100 i3s roll out per day. Source: BMW AG

The rear-hinged passenger doors on the i3 (called “coach doors” by BMW) eliminate the need for a center pillar in the Life Module and give the car a more open feel, despite its relatively small size.

A sustainable supply chain

To realize the Life Module, BMW launched what has since become the largest and most complex composites material and fabrication supply chain ever established for a production automobile. It vertically integrates every aspect of the Life Module’s journey, from the spinning of the polyacrylonitrile (PAN) fiber precursor and fiber carbonization to the conversion of fibers to fabric and fabrication of the carbon fiber structures themselves.

In just five years, the i3 has become the first series-production consumer vehicle in the world to make extensive use of carbon composites in primary structural components. And long before the first i3 rolled into an auto dealer showroom in late 2013, the project had driven a growing group of other auto OEMs to embark on similar paths — a sign that BMW might be the first to successfully complete the journey but won’t be the last to attempt it (see, for example "The markets: Automotive (2014)," under “Editor's Picks” at to right).

Visitors and employees at the Leipzig site’s three-story reception/administration center get a striking reminder of the plant’s core purpose in this overhead stream of semifinished bodes-in-white. Source: BMW AG

CW was offered a chance in March 2014 to visit BMW Group’s i3 manufacturing and assembly facility in Leipzig, Germany. That visit was the genesis of the following firsthand account of the materials and processes BMW engineers used to make this car and the challenges they met and overcame.

Molding the Life Module

The manufacture of every carbon fiber part produced for the i3 actually begins far away, in Otake, Japan, where a joint venture of Mitsubishi Rayon Co. Ltd. (Otake) and carbon fiber maker SGL Group (Wiesbaden, Germany), called MRC SGL Precursor Co. Ltd. (MSP), produces the PAN precursor required for the manufacture of the carbon fiber used in the car.

The precursor is delivered to another joint venture, this one between BMW and SGL, called SGL Automotive Carbon Fibers (SGL ACF). Based in Moses Lake, Wash., U.S., to take advantage of relatively inexpensive hydroelectric power there, the SGL ACF facility is dedicated exclusively to supplying BMW, and it produces 50K tow on two production lines with a total nameplate capacity of 3,000-metric tonnes/6.613 million lb (see "SGL Automotive Carbon Fibers plant’s two fiber lines in production”). The facility was designed with expansion in mind and, indeed, demand for the i3, coupled with BMW’s plans for carbon fiber use in other vehicles, has prompted BMW and SGL to triple the plant’s production.

Step 1: In the CFRP Building, carbon fiber fabrics for the life module (cut and kitted by BMW in Wackersdorf, Germany, then delivered to Leipzig) are sprayed with a thermoplastic binder. Source: BMW AG

From Moses Lake, carbon fiber roving is sent to a second SGL ACF manufacturing facility in Wackersdorf, Germany. Here, the fiber is converted into a variety of fabric forms, including unidirectional tapes and multiaxial weaves (±45°/90°). These are cut, kitted and stacked in preparation for resin transfer molding (RTM).

RTM’d parts for the i3 Life Module are actually produced at two BMW facilities in Germany: Leipzig and Landshut (northwest of Munich). BMW Leipzig, which opened in 2005, is the principal i3 manufacturing hub. It RTMs all part numbers for the i3 and also houses assembly operations for the Life Modules and subsequent integration of Life Modules and Drive Modules. The Landshut plant provides supplementary production of certain components, using identical processes and equipment.

Step 2: Each i3 Life Module comprises 39 different stacked kits, which are used to make 49 preforms, which are then combined to produce 16 resin transfer molded parts. Source: BMW AG

Located just northwest of the city in an open, sprawling industrial park, the Liepzig campus hosts 10 buildings and is bordered on one side by four 2.5-MW wind turbines, which provide some, but not all, of the power consumed by the facility. The complex of buildings is dominated at its core by the structure that serves as the main entrance and architectural focal point — an imposing glass-and-concrete structure that conveys the modernity of the plant and the company. Inside is a three-story vaulted hall that is home to several functions presented in layers. Its reception area is backed by an elevated bank of desks, arrayed in cubicles and glassed-in offices. Overhead is a conveyor system on which BMW’s production bodies-in-white move through the hall from the adjacent assembly plant on their way to paint booths elsewhere. This striking feature, visitors are told, is intended as a continual reminder to the plant’s employees of the importance and immediacy of the job at hand — making cars.

Six of the 10 buildings at BMW Leipzig are devoted to manufacture and assembly of standard (gas-powered) BMW models, including the X1, the 1 series (5-door) and the 2 series (coupe). Buildings 7 through 10, however, are devoted to BMW’s i-series vehicles. BMW reportedly invested €400 million ($597 million) in these manufacturing facilities, which turn out the i3 and the hybrid-electric i8 sports car, due out late this year.

Step 3: Kitted fabrics are preformed in a Fill Gesellschaft (Gurten, Austria) Preformliner press. Shown here is a part preform, fresh out of the press and ready for trimming and stapling. Source: BMW AG

Molding the Module

The i3 Life Module, in its finished form, looks like a basic body-in-white car frame, but comprises several carbon fiber composite components that are adhesively bonded. Its components take shape in what BMW calls the CFRP Building. The kitted carbon fiber fabrics, produced in Wackersdorf, are delivered here for preforming, resin transfer molding (RTM) and preparation for assembly as part of the Life Module.

The most important person in the CFRP Building is a youthful, energetic and busy engineer named Rene Koschkar, head of production planning, carbon fiber parts at BMW. Standing on a mezzanine that overlooks the composites manufacturing floor, Koschkar explained the materials, tools and equipment used to fabricate the Life Module.

When kitted stacks arrive from Wackersdorf, he explained, the plies in the stacks are first stapled together to prevent slippage and then delivered to one of three Fill Gesellschaft mbH (Gurten, Austria) Preformliners in use in Leipzig. There, the stack is placed in a heated preforming mold where a thermoplastic binder is applied to the carbon fiber. The Fill Preformliner press then preforms the stack to conform it to the shape of the mold. Next, the preformed stack is transferred to a cutting station, where an ultrasonic knife is used to trim the preform to near-net shape.

Step 4: Pressed preforms are cut to near-net shape, stapled together to maintain proper orientation during injection, and then laid up in a mold for resin transfer molding (RTM). Here, a technician loads a Life Module side-frame preform into its mold (this task is now automated) prior to resin impregnation, via KraussMaffei injection unit, and cure in a Schuler press. Source: BMW AG

Koschkar noted, here, that BMW has worked hard to minimize touch labor in composites manufacturing, relying on robotics wherever possible to staple, move, place, remove and cut stacks and preforms. This is particularly important, he pointed out, as the i3 approaches rate production, to ensure efficiency and repeatability in its manufacturing processes.

Following ultrasonic cutting is the most important step in the fabrication process: high-pressure resin transfer molding (HP-RTM). The Leipzig plant is equipped with seven 3,000-ton hydraulic presses supplied by Schuler Pressen GmbH (Waghäusel, Germany). Each is serviced by two KraussMaffei (Munich, Germany) HP-RTM injection units. Preforms are robotically placed in steel molds in the Schuler presses, followed by mold closure and resin injection. (The Landshut facility has three Shuler presses and six KraussMaffei HP-RTM injection units).

Step 5: In the Leipzig Body Shop, RTM’d parts for the Life Module are brought together. Before assembly begins, each side frame has hinge and crash reinforcements attached robotically. Source: BMW AG

The resin matrix is Huntsman Advanced Materials’ (The Woodlands, Texas and Basel, Switzerland) Araldite LY 3585 epoxy with Hardener XB 3458. It’s injected, says Koschkar, at more than 40 bar/580 psi. Huntsman says the epoxy can be cured in as few as five minutes at 100°C/212°F. Koschkar would not reveal the actual cure time BMW has achieved except to say that it is “less than 10 minutes” and enables BMW to meet its rate production requirements.

Koschkar also told CW that BMW is comfortable with the preforming and RTM process it has in place, noting, “we have 10 years of experience with the M-series roof.” This is a reference to BMW’s M-series car, which offers a carbon fiber roof made via RTM. And, he adds, “We have fewer problems with dimensions with our carbon fiber parts than we do with sheet metal.”

That said, Koschkar admits that BMW is constantly looking for opportunities to improve materials and process. “Our biggest challenge with RTM is curing of the part — filling the part without dry spots,” he notes. Outside of RTM, he says, “our big challenge is how to reduce our scrap. We are always looking at ways to save material.” This has led BMW to assess increased use of glass fiber instead of carbon fiber in some parts of preforms where material is sacrificed. The company is also looking at ways to reduce resin use via more efficient injection, and Koschkar notes that BMW is keeping a close eye on thermoplastic material options as well.

Step 6: Life Module assemblies are adhesively bonded in an entirely automated process. Here, three of the 173 ABB robots in the Body Shop put the finishing touches on a bonded module. Source: BMW AG

Wackersdorf produces 39 different stacked kits for the i3 Life Module, and from these, BMW in Leipzig and Landshut produces 49 preforms (some stacks produce more than one preform). These preforms are then combined to mold, ultimately, 16 carbon fiber parts for the i3. The largest and most complex carbon fiber structures made for the Life Module are the left hand and right hand side frames. Each comprises nine preforms that are placed in one mold. The dimensional stability and strength of this structure are both critical parameters, because, as will be shown, much of the i3’s subsequent form and assembly process is oriented around these parts.

After cure, parts are robotically demolded and transferred to one of two sandblasting stations for removal of mold release and other contaminants. Clean components are then moved to one of four KMT Waterjet Systems Inc. (Baxter Springs, Kan., U.S.) waterjet cutting machines for trimming and hole drilling. Koschkar pointed out that process control at the plant is such that discovery of fatal flaws in finished parts is rare. Quality assurance, therefore, is performed on a randomized basis only, using a nuclear magnetic resonance technology that reveals dry spots and delamination problems.

After trimming, drilling and (if necessary) quality assurance is complete, the carbon fiber composite parts are deemed ready for assembly, loaded into specialized racking systems, and then transferred to the Body Shop.

Step 7: The i3 roof features carbon fiber recycled from scrap generated during Life Module processing. The stitched, nonwoven fabric allows BMW to give the car the highly prized “carbon fiber look” and enhances the vehicle’s sustainability. Source: BMW AG

Life Module assembly

Housed in a separate building on the Leipzig campus, the Body Shop supports some of the most technically complex aspects of i3 manufacture — assembly of the Life Module’s 16 RTM’d parts. The job is complex for two reasons: First, no mechanical fasteners are used to attach one part to another — the Life Module is completely adhesively bonded. Second, no touch labor is involved in Life Module assembly — adhesive application and part manipulation are automated.

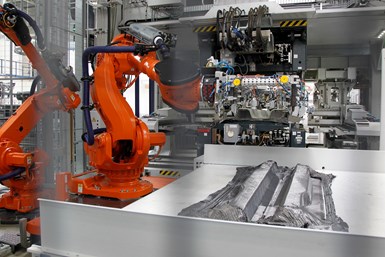

Body Shop head Ralf Brüggemann, like Koschkar, manages most of the operations in the facility from a mezzanine that overlooks the plant floor. At first glance, the Body Shop visitor confronts a sea of orange robots (173 in all, supplied by ABB Robotics, Zurich, Switzerland), constantly turning, rotating, lifting and placing black carbon fiber parts and structures in an array of discrete, enclosed assembly cells. Only occasionally does one see shop personnel move components from one cell to another.

With Brüggemann’s guidance, it becomes clear how the facility functions. Life Module assembly starts with the addition to each side frame of other parts, including door-hinge reinforcements and a door latch (both metal), an injection molded thermoplastic honeycomb crash-protection system (mounted along the frame bottom) and a 2-inch/51-mm diameter braided carbon fiber roll with a foam core, which provides support in case the car rolls during an accident.

After all side frame hardware is mounted, robots begin the task of integrating the side frames with the floor assembly and other structures. This is done exclusively with BETAFORCE, a polyurethane-based adhesive supplied by Dow Automotive (Auburn Hills, Mich. and Schwalbach, Germany) that is applied in the robot-equipped cells.

Step 9: As final assembly of the i3 begins, the carbon fiber roof is lowered into position for attachment to the Life Module. Source: BMW AG

Brüggemann said each Life Module consumes 160 linear m/525 linear ft of adhesive, and added that BMW spent considerable R&D time determining how much adhesive to apply and where to apply it, to achieve the necessary bond strength. This involved careful measurement of adhesive bead height and width and how this correlates to the height and width of a compressed adhesive bead. In the end, says Brüggemann, BMW sought a compressed adhesive bead width of 20 mm/0.8 inch at a height of 1.5 mm/0.06 inch and learned that an applied bead width of 8 to 9 mm (0.3 to 0.35 inch) met that requirement. The goal, then, is to have each adhesive-application robot meet that bead width specification.

It takes three to four hours for BMW to assemble each Life Module. To speed adhesive curing on some parts, attending robots feature a series of small heat lamps on their end-effectors, which generate localized heat at the bond line. Dow says BETAFORCE cure time is about one minute, but that heating of the type BMW applies can shorten that time significantly. To verify bond integrity, says Brüggemann, BMW relies on ultrasonic scanning and, occasionally, dismantles a finished Life Module to assess bond strength and fidelity. “We are at 99.7 percent quality,” Brüggemann claims, but adds, “we are always chasing higher quality.”

Brüggemann, who has experience in other BMW assembly plants, also says that the i3 Life Module Body Shop is “less complex than a steel body shop. Lighter weight makes product handling much simpler.”

Step 10: An i3 Life Module, with doors and glass installed, is lowered onto a Drive Module, the aluminum-framed lower section of the car that incorporates the batteries, motor and wheels. Source: BMW AG

Putting it all together

Finished Life Modules leave the Body Shop ready for integration with the rest of the i3 vehicle. This is done in a third facility on the Leipzig campus where Life Modules and Drive Modules finally meet on one of two i3 assembly lines. There, automated carriages transport i3s from station to station along the assembly line.

Assembly starts with the Drive Module, which arrives with batteries, motor and wheels intact on an aluminum frame. Before the Life Module joins the Drive Module, BMW adds the carbon fiber roof, doors, windshield and other glass. The roof is fabricated from a stitched, nonwoven carbon fiber fabric supplied by SGL ACF. Notably, the fabric is made from carbon fiber scrap material leftover from the i3’s weaving and HP-RTM manufacturing processes.

The doors, fenders and hood of the i3 are injection molded from an unreinforced polypropylene/ethylene-propylene-diene monomer (PP/EPDM), a “thermoplastic vulcanizate.” Virgin and recyclate grades of the material are used, respectively, for the exterior and interior sections. (For more on i3 body panels, see the “Molding i3 body panels" sidebar at the end of this article or click on its title under "Editor's Picks").

This view of the i3 CFRP Building from its mezzanine shows one of Leipzig’s three Fill Preformliner presses (foreground). Behind it are the seven Schuler presses, each equipped with two KraussMaffei resin transfer molding injection units. Source: BMW AG

The partially assembled Life Module is then placed atop the Drive Module frame and attached with adhesive and 10 screws. Following this, the vehicle’s interior is pieced together, including seats, dashboard and dashboard components. Lighting systems for the headlamps and taillamps are added, as are fenders, motor and hood.

Despite speculation in the automotive press that BMW has been unable to meet i3 production rates, BMW officials in Leipzig told CT as the June issue went to press that the rate was up to 100 vehicles per day (approaching 36,500 per annum) — on par with expectations. Further, said one official, “that number is always growing.”

Adjacent to the i3 vehicle assembly line, BMW will soon begin assembly of the i8, the second in what auto bloggers believe will be a number of BMWs that will eventually bear the i prefix. Like the i3, the i8 also features a Life Module. And it, too, is a carbon fiber composite assembly, but one that is, according to one BMW engineer, “more complex.”

The Life Module Body Shop features 173 ABB 6-axis robots, each working in cordoned-off cells. Employees only touch parts to move them from cell to cell, delivering them on specialized racks through cell doors that segregate man and machine. Source: BMW AG

Complexity seems to be a key descriptor when it comes to molding carbon fiber parts for a series electric vehicle (EV). Yet BMW appears to have managed the i3 Life Module’s progress from carbon fiber precursor to its place as the carbon fiber passenger protection cell on this premier EV with relative ease. Drawing on a wealth of experience, a secure supply pipeline and strong support from material and machinery suppliers throughout the composites industry, the company promised a comfortable, well-designed, lightweight, efficient car. Now, it’s delivered. That has silenced doubters and positioned BMW in the lead as the automotive industry begins its conversion to composites.

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRevisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreRead Next

Auto composites quest: One-minute cycle time?

Faced with high fuel prices and ever-more stringent restrictions on tailpipe emissions, automakers are taking composites into their own hands.

Read MoreAutomotive CFRP: The shape of things to come

CAFE and CO2 emission standards will drive auto OEMs to fully examine the physics of fuel economy, but will that, at last, steer them toward extensive use of carbon fiber composites?

Read MoreCutting engine weight via thermoplastic composite guide vanes

Greene Tweed replaces metal stator vanes with its DLF material co-molded with a metal leading edge that meets performance, cost and high-rate production targets while cutting 4 kg per engine.

Read More