Dash-CAE launches low-cost carbon fiber monocoque for road cars

The Formula 1 supplier delivers the TR01, an affordable, versatile and lightweight composite chassis that opens new possibilities for hypercar, supercar and motorsport projects.

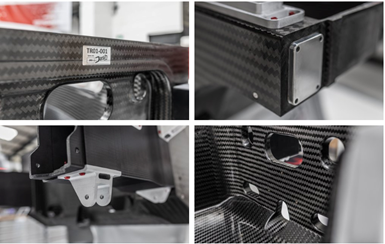

Advanced engineering company Dash-CAE (Abingdon, U.K), with it’s DNA derived from Formula 1 (F1) technology, has launched a new carbon fiber monocoque chassis, the TR01. Delivering a step change in price-to-performance ratio, the chassis enables an affordable and versatile solution for hypercar, supercar and motorsport projects in the growing performance automotive and motorsport industries.

Dash developed the TR01 chassis to fulfill an unaddressed market need for an affordable, high-performance, “off-the-shelf” carbon fiber monocoque chassis. As a large, one-piece component, chassis manufacture is reported to be challenging — particularly when performance, quality and consistency are concerned.

According to the company, TR01 is suitable for any two-seat vehicle requiring a lightweight and stiff carbon fiber monocoque and, although predominantly standardized, can be adapted to customer requirements. It offers a stiffness of 35,000 Nm/Deg, weighs only 50 kg and is priced under £30,000 — around 50% less than those currently available. The TR01 also provides the versatility to accommodate different front/rear ends plus powertrains.

Customers can customise the TR01 chassis to better suit their specific applications, including modification of the center console design. The chassis was developed with structural analysis to ensure that the chassis could meet EuroNCAP/FMVSS test standards and provide optimal crash protection.

Dash leverages its in-house expertise in design, engineering and manufacturing to deliver high-quality composite and additive manufacturing (AM) solutions for projects across various industries. The company’s comprehensive capabilities include computer-aided engineering (CAE) and design, composites understanding, engineering and manufacturing, including advanced AM, tooling and more. The TR01 leverages the company’s extensive history of engineering and manufacturing for high-profile motorsport teams and programs.

“The TR01 chassis opens new possibilities for niche automotive manufacturers, and larger international OEMs by offering an affordable, versatile, lightweight, and high-stiffness carbon [fiber] monocoque chassis,” Tim Robathan, CEO of Dash, says. “These programs are often expensive and the ability to use a production carbon monocoque is a huge time and cost saving, without compromising performance.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

The making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.