Composites Index contracts on weak exports

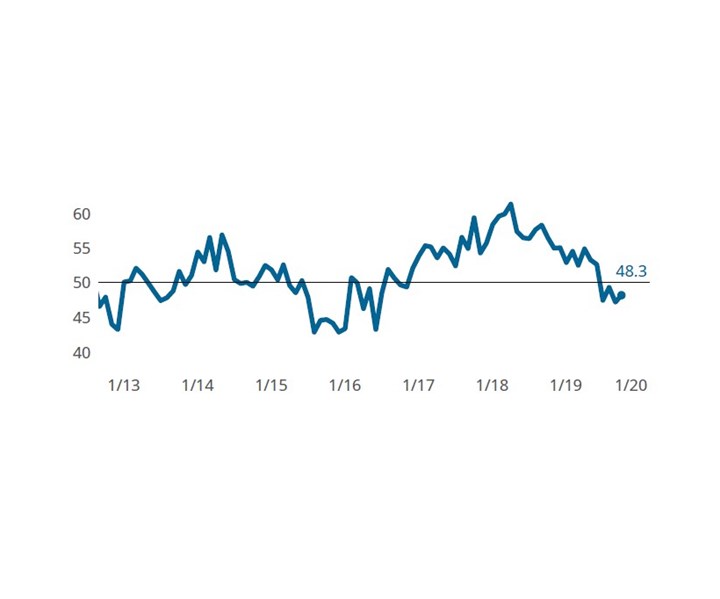

The Composites Index experienced further contraction in business activity in October, with a reading of 48.3, led by steep contraction in export orders.

Fourth month of contracting activity. The Index contracted during October as expanding activity in new orders, production and employment were insufficient to offset contracting activity in supplier deliveries, exports and backlogs.

Registering an October reading of 48.3, the Composites Index signaled a further contraction in business activity. Index readings above 50 indicate expanding activity, while values below 50 indicate contracting activity. The further away a reading is from 50, the greater the change in activity. Gardner Intelligence’s review of the data found that in October 2019, total new orders expanded, while export orders contracted at its fastest rate in more than three years.

The Index was bolstered by expansionary readings for production and employment; however, contractionary readings for supplier deliveries, exports and backlogs pulled the Index — calculated as an average of its components — lower during the month, resulting in the contractionary reading.

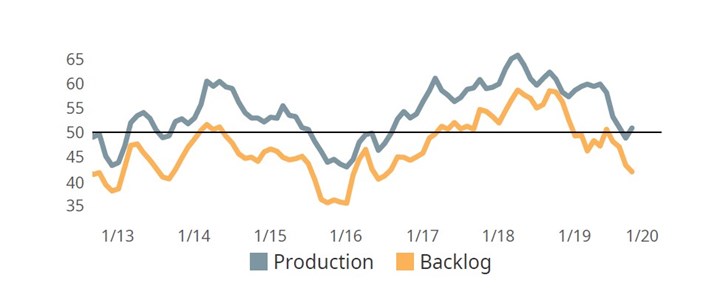

Falling backlogs are stabilizing production activity. Despite growing activity in domestic orders, the overall data suggest that fabricators are heavily relying on their backlogs in order to maintain stable production levels.

The combination of expanding total orders and contracting exports implies that domestic orders expanded briskly in October. Despite this, strongly contractionary backlog readings in the second and third quarters of the year suggest that some of the strength behind recent production readings may be from a reduction in backlogs rather than the fulfillment of new orders.

In its September column, Gardner Intelligence stated its concern over the potential for weak future supplier delivery readings given the recent trends in production and orders data. October’s supplier delivery reading fell more than five points and registered its first contractionary reading since late 2016.

More information about the Composites Fabricating Index can be found at http://www.gardnerintelligence.com/.

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

.jpg;width=70;height=70;mode=crop)