Composites Processes

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

Narrow Your Processes Search

Latest Processes Articles

VIEW ALLAirbus video highlights RACER compound helicopter first flight

Launched as part of a Clean Sky 2 program, a compound design — rotor, split fixed-wing, propulsive propellers — uses composites to cut fuel consumption and emissions by 20%.

WatchCEAD, AES kick off U.S. symposium highlighting LFAM ecosystem

CEAD Flexbot print cell demonstrations and industry presentations showcased the emerging options in 3D printing for polymers, composites and more at AES’ Akron facility.

Read MoreAitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.

Read MoreMFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

Read MoreLarge-volume VFGF extrusion printer facilitates modular composite cockpit

Queen 1 system from Q.Big 3D produced complete cockpit assembly of a full flight simulator in a little more than a month, enabling fast build speeds, high surface quality and dimensional accuracy.

Read MoreCom&Sens presents workshop on fiber optic sensing for COPVs

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.

Read MoreKnowledge Centers

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

LEARN MORE

Closed mold processes offer many advantages over open molding. This knowledge center details the basics of closed mold methods and the products and tools essential to producing a part correctly.

LEARN MORELatest Processes News And Updates

UMaine’s novel polymer 3D printer surpasses former Guinness World Record

Four times larger than its 2019 predecessor, Factory of the Future 1.0 offers new opportunities in composite materials, including development of recycled and bio-based materials, opening up new research frontiers.

Read MoreVoxelMatters report reveals top companies in composites AM

The new market study identifies key players in a $785 million global market that has grown by 21% year on year.

Read MoreBelotti, Cosberg partner for advanced automated assembly solutions

The Italy-based companies merge technological know-how to develop novel systems for the processing and assembly of light alloys and carbon fiber components.

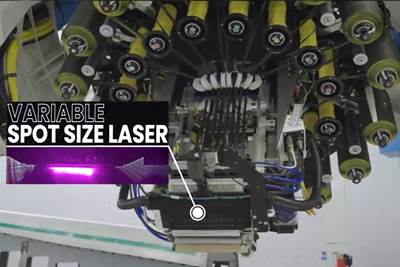

Read MoreElectroimpact offers variable spot size laser AFP 4.0 technology

Patented process technology increases quality, reliability and machine utilization for composite laminate production.

Read MoreILAuNCH Trailblazer project to use AM technologies to produce large-scale composite rockets

ILAuNCH partnership, joined by ANU and New Frontier Technologies, will develop a qualified manufacturing process that will directly contribute to the development of launch vehicle development.

Read MoreMaterialise adds three materials to enhance industrial 3D printing

Materialise expands additive manufacturing portfolio with early adoption of new HP PA 12S and integration of PA 11 and PA-CF materials.

Read MoreFeatured Posts

Designing an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

WatchFrom the CW Archives: The life and death of the BMW i3

A look back at the ambitious and impressive composites production system BMW developed for production of the all-electric i3 EV.

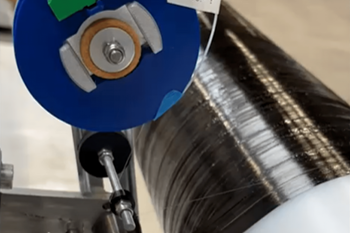

Read MoreOptimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

WatchCarbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

WatchAI-powered robotic solutions support high-mix manufacturing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

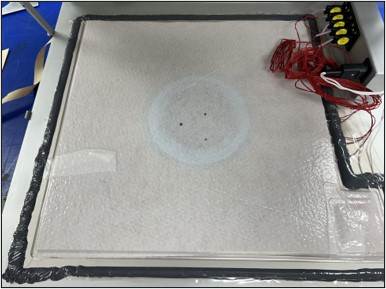

Read MoreRevisiting the double vacuum debulk process

Evolution of the double vacuum debulk (DVD) process over the years continues to advance its “near autoclave quality” for low-void, highly compacted repair patches.

Read More

.jpg;maxWidth=300;quality=90)