Composites Cutting/Kitting

Kitting and cutting are crucial processes in composite manufacturing, involving the precise preparation and shaping of materials before their assembly into final composite structures. Kitting involves organizing and preparing the composite materials—such as fibers, fabrics, or pre-impregnated sheets—according to specific designs or patterns. Precision cutting then follows, utilizing specialized machinery or tools to accurately shape these materials based on predetermined templates or CAD designs.

Latest Cutting/Kitting Articles

VIEW ALLAitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.

Read MoreOptimized, automated manufacturing concepts for composite parts, SMC semi-finished materials

JEC World 2024: The AutoCut Pick&Place and Cube SMC line from Schmidt & Heinzmann aim to deliver more modernized manufacturing capabilities with improved efficiency and process control.

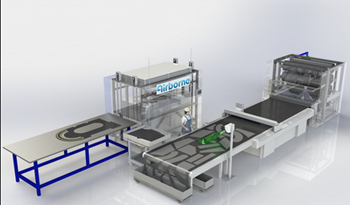

Read MoreAirborne to supply composites cutting/kitting equipment to Airbus Helicopters

Fully digital Kit by Light systems will enable faster, simpler and more efficient composite ply management at Airbus’ Donauwörth facility.

Read MoreSGL Carbon offers customizable, prefabricated composite textile stacks

SGL aims to eliminate the work involved from material roll to stack for customers entirely, cost-effectively pre-cutting and assembling Sigratex stack packages to application specifications, saving time, cost and waste.

WatchState-of-the-art composites cutting, machining solutions ensure accuracy, ease of operation

JEC World 2024: Compcut is presenting its advanced composites saw (ACS) and precision composite router (PCR), in addition to inviting attendees to bring their own materials for demonstration purposes.

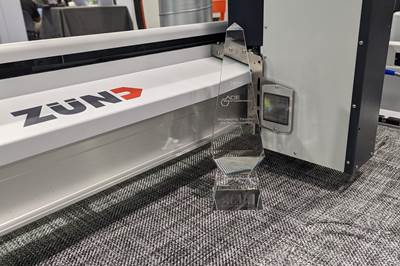

Read MoreIntelligent, automated production methods for composites cutting, logistics

JEC World 2024: Zünd is highlighting digital excellence via its ZCC Cut Center, heat sealing module (HSM), G3 Cutter and ZPC software.

Read MoreKnowledge Centers

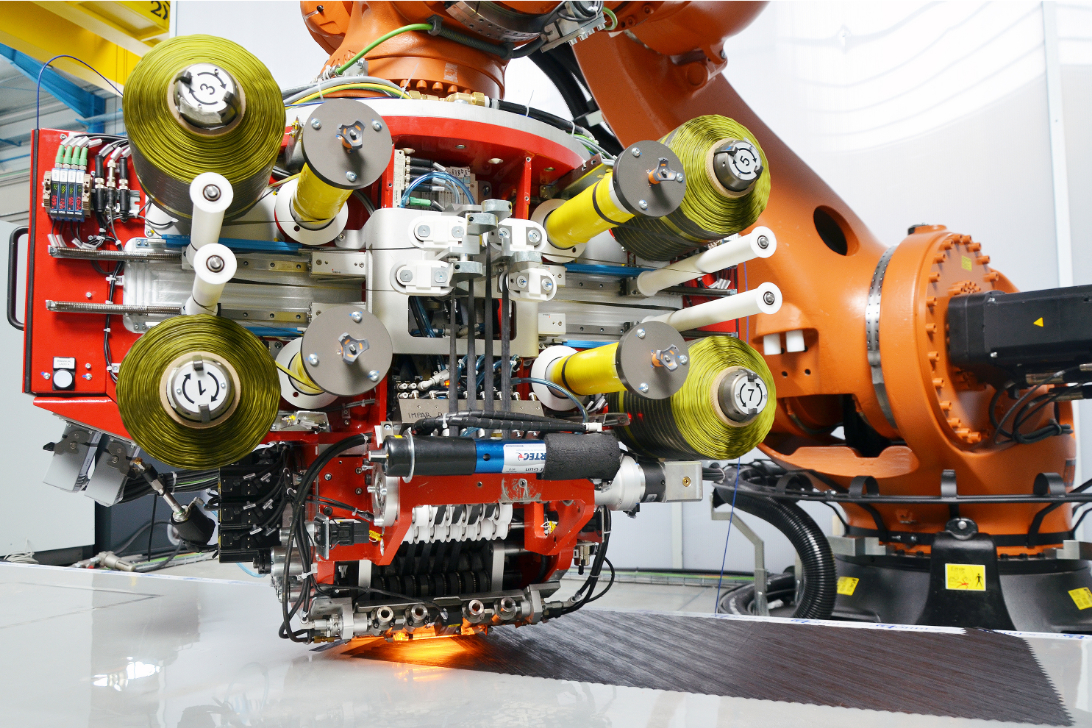

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORE

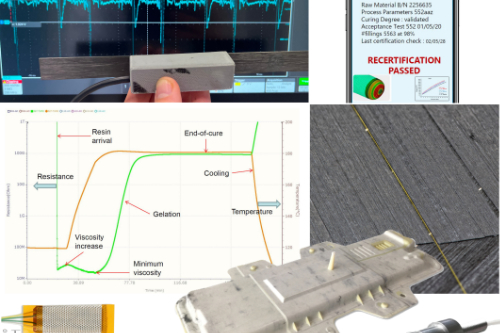

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORELatest Cutting/Kitting News And Updates

Dieffenbacher highlights Fibercut system for increased productivity

Dieffenbacher’s fully automated cutting and stacking system enables automated SMC processing applications.

Read MoreBeSpline wins IBEX Innovation Award, announces partnership with Boston Boatworks for Shaped Foam Kits

CAD-driven fabrication uses adaptive mold technology for lighter, stronger, higher quality boat structures without time and cost of building a mold while drastically reducing core fitting time for yacht builders.

Read MoreCompcut features ACS, PCR composite cutting technologies

Advanced plate saw and precision router provide precise, fast and efficient cutting of composite test specimens.

Read MoreZCC Zünd Cut Center ushers in enhanced digital cutting automation

ZCC V.4 supports operators with several new smart, intuitive digital cutting functions throughout the composite material handling workflow.

Read MoreDigital composite cutting, kitting made clean, simple and productive

CAMX 2023: Zünd is exhibiting its heat-sealing module in operation with a G3 cutter configuration and Robot PortaTable 130 to emphasize its fully digital cutting capabilities from prepreg to thermoplastics.

Read MoreAerospace manufacturer meets increased demand with Plataine

Plataine’s AI-based solution, incorporated into the composite aerostructure manufacturer’s cutting and kitting operations, increased production throughput, material use, improved quality and reduced errors.

Read MoreFeatured Posts

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreImprove production with five-axis machines built for composites

Virtually tour (4) USA-Made 5-Axis CNC Machines designed and engineered to help companies improve profits by decreasing cycle times and improving part quality. (Sponsored)

WatchPlant tour: Bucci Composites, Faenza, Italy

A stalwart in Italy’s “Motor Valley” opens its doors for a discussion and exploration of the company’s history in composites manufacturing for high-performance cars and other applications.

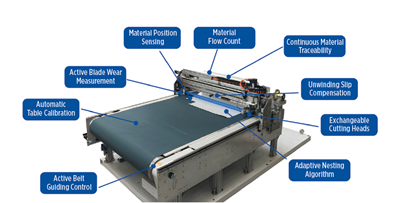

Read MoreModular cutting and stacking system advances flexible, fully automated operations

Integration of next-gen cutting and stacking systems into production lines brings new level of efficiency, quality control.

Read MoreDesigning for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

Read MoreThermoplastic tapes continue to show potential for composite aerostructures

Web Industries reports increased R&D activity within several aerospace markets enabled by the flexibility and advantages of thermoplastic tapes.

Read More

.jpg;maxWidth=300;quality=90)