Composites Use in Aerospace

Advantages of building aircraft structures with composites, compared to metal, include light weight, high specific strength, superior fatigue properties, damage tolerance and the absence of corrosion. In the 1950s, Boeing began using fiberglass in its 707 passenger jets, and at the time the material made up about 2% of the overall aircraft by weight. Since then, Boeing, Airbus and other aircraft manufacturers have continued to increase this percentage with successive aircraft models. Today’s twin-aisle commercial aircraft such as the Boeing 787, first launched in 2009, and the Airbus A350 comprise approximately 50% composites by weight, largely carbon fiber-reinforced polymer (CFRP).

Latest Aerospace Articles

VIEW ALLSubmit abstract to speak at CW New Space Tech Days in November

One-day online event in winter 2024 will feature six presentations exploring the increasing importance of composites in the evolving space market. Abstract deadline is July 5.

Read MoreAirbus finalizes Aerovel acquisition

Per the agreement, Aerovel’s Flexrotor, a vertical takeoff and landing UAS aircraft, will provide enhanced and expanded mission capability offerings to Airbus customers.

Read MoreAirbus video highlights RACER compound helicopter first flight

Launched as part of a Clean Sky 2 program, a compound design — rotor, split fixed-wing, propulsive propellers — uses composites to cut fuel consumption and emissions by 20%.

WatchGTL validates LH2 composite dewar tanks for use in aviation

Test results exceeded expectations regarding holding hard vacuum, heat load, rapid chill-down and hydrogen fraction goal, leading to flight prototype fabrication.

Read MoreNIAR receives $10 million NASA funding for high-temp advanced materials

Specialized research program will develop, mature and implement composites and other novel materials for use in hypersonic vehicles.

Read MoreManuela Marangio heads Leonardo Aerostructures Division at Grottaglie facility

Female mechanical engineer is responsible for Leonardo Aerostructures’ entire production engineering plant, dedicated to several major aeronautic programs.

Read MoreKnowledge Centers

Review the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

LEARN MORE

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

CompositesWorld’s CW Tech Days: Infrastructure event offers a series of expert presentations on composite materials, processes and applications that should and will be considered for use in the infrastructure and construction markets.

LEARN MORELatest Aerospace News And Updates

FACC records more than 24% revenue growth in Q1 2024

Workforce expansion, new contracts and diversified portfolios, supply chain stabilization and footprint expansion may lead to €810-850 million revenue for the 2024 financial year.

Read MoreJCB Aero aircraft interior flooring panels incorporate SHD composites

High-performance carbon fiber prepreg using SHD’s FRVC411 epoxy resin system resulted in a durable, compliant design for the MRO market.

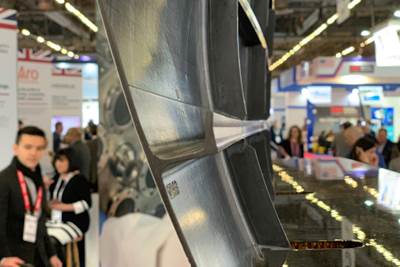

Read MoreNew CMC turbine vanes successfully tested in wind tunnel

SiC/SiC ceramic matrix composite (CMC) inlet guide vanes for a high-pressure turbine are aimed for a geared turbofan and show promise for more efficient aeroengines with less weight and need for cooling.

Read MoreSyensqo introduces AeroPaste 1003 aerospace adhesive

Two-part room-temperature paste increases high-rate assembly and joining efficiencies when bonding metallic and composite parts.

Read MoreCryomotive prepares CcH2 storage for demonstration on heavy-duty trucks

Cryogas system is based on carbon fiber towpreg wrapped Type 3 inner tank at 400 bar storing 38 kilograms of CcH2.

Read MoreAitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.

Read MoreFeatured Posts

Aviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreJEC World 2024 highlights: Forwarding initiatives surrounding sustainability and mobility

Themes at the forefront of JEC World 2024 included solutions for mobility applications and sustainable materials, technologies and processes for composites manufacturing.

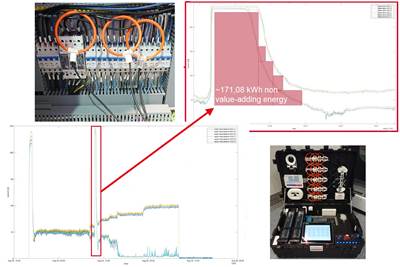

Read MoreMeasuring energy use to enable sustainable composites production

Airbus subsidiary CTC uses new technology to measure energy use in machine components and processes to optimize equipment, production lines and guide decisions for future composites.

Read MoreFrom the CW Archives: I see thermoplastics in your future

Thermoplastics are evolving quickly into larger structures and clearly will have a significant role to play in the next commercial aircraft program — whenever that’s announced. This edition of “From the CW Archives” looks back on a thermoplastics pioneer.

Read MoreEaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

WatchFAQ: Aerospace

How are composites used in aerospace structures?

Since the 1950s, composites have been growing in use in commercial and defense aircraft, ranging from struts and tail components, to wing skins and fuselages, to engine components and propeller blades.

One of the largest challenges to adoption of composites by the aerospace industry is stringent standards especially for safety critical structures, necessitating time- and labor-intensive processes to qualify new materials for use on passenger aircraft.

Qualified and well-tested autoclave-cured carbon fiber and thermoset-based prepregs are most often used for many structures, though other materials and formats, including thermoplastic tapes, are also in development or use.

How are composites used in space structures?

At the time the Apollo capsule, which landed on the moon in 1969, was built by NASA, composites industry was still in its infancy and the materials were not yet in widespread use, though the Apollo capsule used early composite technology in the form of an ablative heat shield made from Avcoat, an epoxy novolac resin with silica fibers in a fiberglass-phenolic honeycomb matrix. A fiberglass honeycomb was bonded to the primary structure and the paste-like material was injected into each cell individually.

Since Apollo, advanced composites have evolved by leaps and bounds, and have played a significant role in space programs with use in launch vehicles, the space shuttle, satellites, space telescopes and the International Space Station.

Source: Composites in the race to space