Composites Use in Pressure Vessels

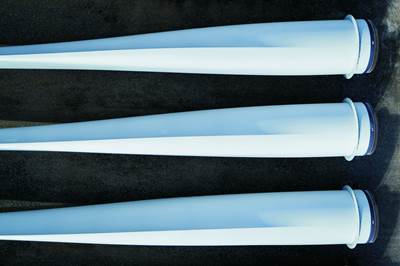

High-pressure gas storage vessels represent one of the largest and fastest-growing markets for advanced composites, particularly for filament-wound carbon fiber composites. Although they are used in self-contained breathing apparatuses and provide oxygen and gas storage on aerospace vehicles, the primary end markets are for storage of liquid propane gas (LPG), compressed natural gas (CNG), renewable natural gas (RNG) and hydrogen gas (H2).

Latest Pressure Vessels Articles

VIEW ALLNREL integrates robotics into wind turbine blade production

Research enables successful automation in post-molding manufacturing operations, which could lead to more competitive U.S.-based blade manufacturing.

Read MoreHexagon Ragasco launches Linktra Smart cylinders in Norway

Fiberglass pressure vessels with IoT provide real-time insight into refilling needs for LPG consumers.

Read MoreCom&Sens presents workshop on fiber optic sensing for COPVs

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.

Read MoreNPROXX powers up H2 tank production with move to Alsdorf facility

Tripled space and capacity to potentially grow composite tank production to 30,000+ tanks/year, equipment investments enable manufacturer to handle larger orders, streamline operations.

Read MoreToyoda Gosei composite hydrogen tanks to be used on passenger ship

Multiple commercial truck-type high-pressure tanks have been extended to maritime applications.

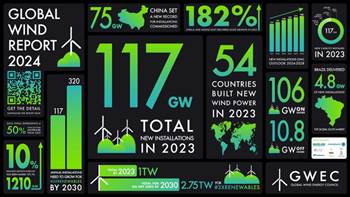

Read MoreGWEC 2024 report highlights positive momentum in wind installation

Global Wind Report describes a record year for wind energy in 2023, but highlights the need for policy-driven action to meet COP28 and 1.5°C pathway targets.

Read MoreKnowledge Centers

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

LEARN MORE

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORELatest Pressure Vessels News And Updates

Noble Gas awarded $500K for conformable, compressed gas storage tanks

DOE MAKE IT prize supports U.S.-based manufacturing of clean energy technology components for a diverse range of market applications.

Read MoreKineco Exel Composites India to supply carbon fiber planks for wind

Multi-year agreement between the joint venture and a South Asian wind turbine manufacturer contributes to composite spar cap development.

Read MoreOcean Winds takes full ownership of SouthCoast Wind project

Madrid-based international company is focused on the joint procurement process for offshore wind in Connecticut, Rhode Island and Massachusetts.

Read MoreHengshen carbon fiber contributes to 143-meter-long MingYang wind blade

First MySE292 offshore wind blade from MingYang Group successfully rolled off the production line in February.

Read MoreSwancor, Siemens Gamesa solidify recyclable wind blade partnership

Swancor will supply all recyclable resin to Siemens by 2026, contributing to RecylableBlade efforts.

Read MoreVoith announces hydrogen storage cooperation with Weifu Hi-Tech

New deal with Chinese auto firm will develop and commercialize Type IV tanks for European, U.S. and Asian business markets.

Read MoreFeatured Posts

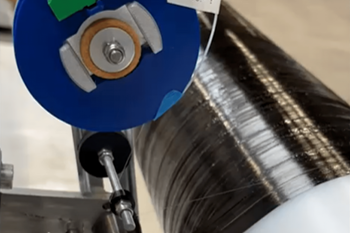

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

WatchComposites end markets: Pressure vessels (2024)

The market for pressure vessels used to store zero-emission fuels is rapidly growing, with ongoing developments and commercialization of Type 3, 4 and 5 tanks.

WatchForvia moves toward more sustainable automotive composites manufacturing

Automotive technology supplier Forvia shares sustainability goals and recent developments aimed at bio-based and recycled materials and ramping up hydrogen tank production for clean mobility.

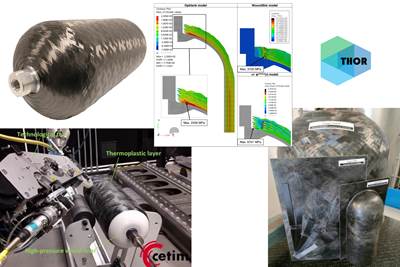

WatchUpdate: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

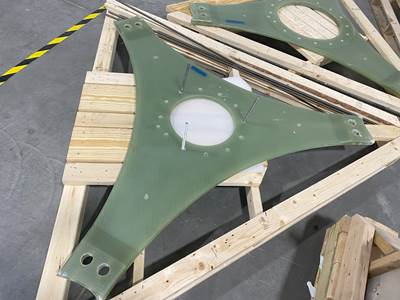

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

WatchComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

WatchFAQ: Pressure Vessels

How are composites used in energy storage?

Composites are used to build pressure vessels to store compressed natural gas, liquid propane gas, hydrogen gas.

These typically involve filament winding of glass or carbon fiber around a metal, plastic or all-composite liner.

What are the types of pressure vessels?

You may see pressure vessels or storage tanks listed as one of various numbered “Types.”

Pressure vessels are organized into five types:

-

-

- Type I: All-metal construction, generally steel.

- Type II: Mostly metal with some fiber overwrap in the hoop direction, mostly steel or aluminum with a glass fiber composite; the metal vessel and composite materials share about equal structural loading.

- Type III: Metal liner with full composite overwrap, generally aluminum, with a carbon fiber composite; the composite materials carry the structural loads.

- Type IV: An all-composite construction, polymer — typically polyamide (PA) or high-density polyethylene (HDPE) liner with carbon fiber or hybrid carbon/glass fiber composite; the composite materials carry all the structural loads.

- Type V: Linerless, all-composite construction.

-

Do composites have a role in the hydrogen economy?

For years, composites have offered lightweight storage of compressed hydrogen (H2) gas for zero-emission, fuel cell-powered vehicles via Type IV tanks comprising plastic liners wrapped with carbon fiber and epoxy resin. Though H2 has long promised a sustainable source of clean energy, until recently, progress was slow.

As the market continues to grow, demand for Type IV tanks continues to increase, with new technologies in development.

Follow CompositesWorld’s continuing hydrogen market coverage for the latest.

Source: The potential for hydrogen to fuel composites growth

.jpg;maxWidth=300;quality=90)