Spirit AeroSystems Belfast advances LANCA project concept with resin transfer infusion

Spirit AeroSystems Belfast, Northrop Grumman and Intrepid Minds support further development of the Royal Air Force’s unmanned Lightweight Affordable Novel Combat Aircraft (LANCA).

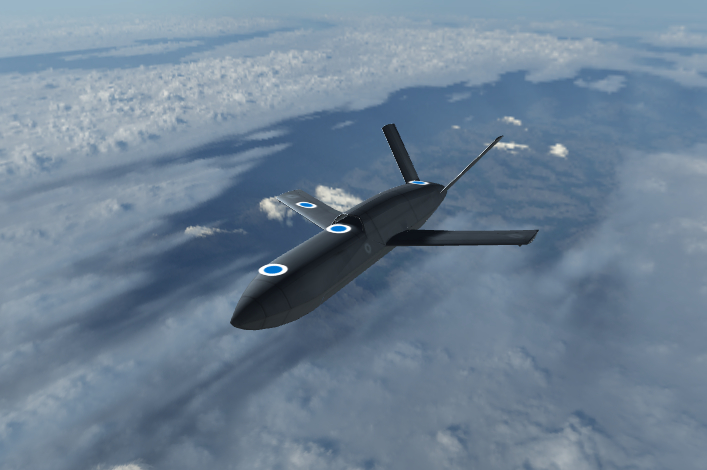

LANCA aircraft concept. Photo Credit: Royal Air Force

Spirit AeroSystems Belfast (Northern Ireland) announced on April 27 it will lead Team MOSQUITO, comprising Spirit Belfast, Northrop Grumman (London, U.K.) and Intrepid Minds (U.K.), on further development of the Royal Air Force’s (RAF) Lightweight Affordable Novel Combat Aircraft (LANCA) concept to full demonstration capability. Initially supporting more than 100 STEM jobs at Spirit Belfast’s facility, the project has the potential to sustain further expertise in the wider U.K. supply chain, and aims to deliver dramatic reductions in traditional cost and development timelines for combat air systems.

Exploiting agile design principles, sophisticated digital applications and advanced manufacturing skills, the team will generate knowledge and evidence for a potential follow-on project. Findings could lead to this capability being deployed by the RAF to enhance protection, survivability and information advantage to aircrews.

Drawing on its expertise in advanced composite manufacturing solutions, Spirit Belfast says it will adapt its resin transfer infusion technology to produce a lightweight vehicle capable of uncrewed, high-speed flight. Benefits of using extensive composite components, compared to all-aluminium aerostructures, include both reduced maintenance and fuel consumption for aircraft operations.

“Spirit Belfast is delighted to lead the delivery of a national program enabling the development of cutting-edge technologies while maintaining critical skills in the U.K.,” says Scott McLarty, senior vice president of Spirit AeroSystems, Airbus Programs. “Supporting the MOD’s [UK Ministry of Defence] strategic objectives on pace, affordability and operational capacity, Team MOSQUITO will help drive collaborative innovation and competitive advantage. We are excited to develop this relationship with a view to contributing to a more sustainable industrial base for U.K. defense.”

In addition to the provision of systems engineering support, Northrop Grumman will supply its international DA/RC (Distributed Autonomy/Responsive Control) technologies, gateway offerings and advanced mesh networking capabilities to the aircraft. These are said to enable seamless human-machine collaboration and cooperative mission management across distributed manned and unmanned assets.

“Our team will help deliver the required development cost and time savings by providing our expertise in Agile development and DevSecOps to enable a model-based, digital design approach,” says Katharine Sealy, director of National Security Solutions, Northrop Grumman UK. “By applying modern software development practices to a digital engineering environment, we aim to dramatically reduce the time required to build a flying demonstrator while allowing for seamless integration of additional future capabilities.”

Further, Intrepid Minds will reportedly cover the complete avionics system, power, lighting and integration with the ground control station. As part of this project, the company brings its own Adrestia system currently being deployed across the air, surface and subsurface domains. Having already integrated into many civil and defence systems, Intrepid Minds is using that speed of development to generate a cohesive structure across all partners and suppliers.

“As specialists in the unmanned and autonomous field, Intrepid Minds has a proven record in developing the art of the possible,” concludes Intrepid Minds Managing Director, Adam Smith. “Our ability to pull in the best technologies from suppliers and integrate them centrally with our Adrestia system and Spectre hardware can rapidly enhance a system of systems approach. We are delighted to be involved in developing potential U.K. sovereign capability in ways that could work across the services.”

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreRead Next

Boeing announces first unmanned Loyal Wingman defense aircraft

The first of three prototypes, the Loyal Wingman’s artificial intelligence application and its use of composites soars above the milestone set for unmanned aircraft.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More