Mito, Cardea Bio spearhead ISO standardization efforts for graphene

Unified draft technical specification brings together industry, academia and the government to develop a classification framework for graphene-related 2D materials.

Left to right: Caio Lo Sardo, Dr. Angela Hight Walker and Brett Goldsmith. Photo Credit: Mito Material Solutions

Specialty chemicals company Mito Material Solutions (Indianapolis, Ind., U.S.) and Cardea Bio Inc. (San Diego, Calif., U.S.) announce significant progress in the international efforts to standardize graphene together with the National Institute of Standards (NIST, Gaithersburg, Md., U.S.). Brett Goldsmith, PhD, chief technology officer (CTO) at Cardea, recently returned from the International Standards Organization (ISO) meeting that took place at the National Physical Laboratory in Teddington, U.K., during which graphene material documentary standards took important steps forward.

“We see a bright future for diagnostic tools based on graphene electronics, but we’re not waiting for that future — we’re making it happen!” Goldsmith says. “Part of that means driving reliability and predictability in the graphene material industry. That’s why we are committed to supporting the Technical Advisory Group (TAG) to ISO TC 229.”

Standardization expertise is supported by staff on NIST’s graphene technical specification team, including senior scientist Dr. Angela Hight Walker. “Graphene will play a major role in multiple industries; developing documentary standards will certainly hasten the pace,” Dr. Walker says. “Leadership by U.S. industry in developing standards is critical for emerging technologies. Having U.S. companies like Mito Materials and Cardea spearhead standards discussions indicates a new threshold of maturity for the U.S.-based graphene industry.”

Titled “The classification framework for graphene-related 2D materials,” the document will move from a preliminary work item to a formal technical specification project as early as spring 2023.

Leading the effort to draft this technical specification is Caio Lo Sardo, vice president of Mito. “Our flagship product, E-GO, is an additive used in materials like fiber-reinforced thermoplastics and thermosets to improve performance in composite applications across several industries,” Lo Sardo points out. “For us to serve growing markets, we need to deliver increasing quantities of materials while also meeting EPA/TSCA registration requirements. As a graphene consumer, we need to be able to ensure that the materials we use are within specs, [are] consistent and meet regulatory standards.” (See “Graphene Council awards verified graphene functionality to Mito Material Solutions.”)

The drafted technical specification is based on the framework created by The Graphene Council (New Bern, N.C., U.S.), a leading industry source for graphene commercial application, production and research intelligence. The Graphene Council’s framework was put together with the help of more than 100 Graphene Council members. “The Graphene Council framework we started with at ANSI was itself ambitious and comprehensive. As a standards draft document, we needed to shift the language and focus to help us work with regulatory bodies with clarity and confidence,” Goldsmith explains.

“In working with Caio on this project, he had this view of graphene that was radically different from mine and the industry we work in,” he continues. “Caio’s interested in bulk powders, plastic mixes and EPA regulations that our business doesn’t have to worry about. I’m focused on graphene monolayers for electronics fab and FDA requirements for medical devices and diagnostics. However, in the end, we found that we both have similar problems. To grow our products, we both need a better regulatory framework for the graphene material vendors we work with. I think that likely led us to the Graphene Council, ANSI and ISO.”

ISO Technical Committee (TC) 229 focuses on nanotechnologies. The group of people working on graphene standards in this committee includes a mix of industry, academia and government lab scientists with a variety of technical backgrounds and perspectives, working as part of the American National Standards Institute (ANSI)-Accredited U.S., TAG to ISO TC 229. These varied perspectives have combined to create a unified draft technical specification that is expected to help drive the commercialization of products that contain graphene by giving industry tools to help separate hype from reality. Titled “The classification framework for graphene-related 2D materials,” the document will move from a preliminary work item to a formal technical specification project as early as spring 2023.

Related Content

Mito to introduce graphene to EV energy storage innovations

Project initiatives for a multifunctional adhesive and addressing EV battery challenges are expected to change the dynamics of energy storage adoption.

Read MoreGIM GrapheneFibre commences commercial graphene-enriched carbon fiber production

Saudi Arabia-based company supports Saudi Arabia’s Vision 2030, contributes to full-scale graphene-based composites for a variety of end market applications.

Read MoreAernnova Composites, leader in composites R&D

This sidebar to CW’s July 2024 feature article reviews the company’s achievements and capabilities through years of composites R&D programs.

Read MoreOn the radar: Reusable launch vehicles, hypersonics make space more accessible

CFRP has become key to targeting efforts in reusing components like rocket stages, as well as the development of reusable hypersonic testbeds and spaceplanes, for increasing space commercialization.

Read MoreRead Next

OCSiAl graphene nanotubes enhance dielectric properties of GFRP pipes

Nanotubes grant permanent, uniform anti-static properties and are compatible with most resin types and manufacturing processes, enabling composite pipe use in high-risk facilities.

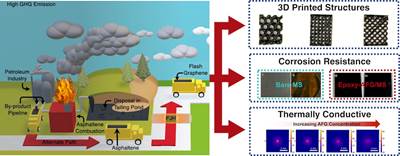

Read MoreRice University turns asphaltene into graphene for composites

University scientists use novel flash Joule heating process to convert crude oil byproduct into graphene, to then be mixed with composites for thermal, anti-corrosion and 3D-printing applications.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More