GFRP trailing edge spoilers for rotor blades achieve 6% AEP increase

evoblade and Deutsche Windtechnik study confirms that the retrofittable Evoflap spoiler improves flow, offers load reduction and could potentially extend wind turbine service life.

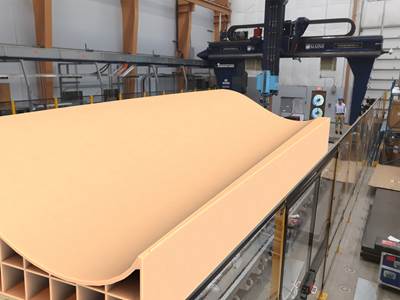

The trailing edge spoiler EvoFlap for the blade root area, divided into seven segments. Photo Credit: evoblade

The wind energy start-up, evoblade, a spin-off of the Institute of Aerospace Technology (IAT) of the University of Applied Sciences Bremen (Germany), has developed a composite retrofittable trailing edge spoiler for rotor blades with the help of Deutsche Windtechnik AG (Bremen) and Wirtschaftsförderung Bremen. The results of a side-by-side testing and optimization study of the EvoFlap now confirm that installing the spoiler can improve the aerodynamic flow in the area of the blade root, resulting in improved efficiency and performance of the wind turbine system.

“Rotor blades have a significant impact on the technical and economic performance of a wind turbine,” says Dr.-Ing. Frank Kortenstedde, founder and CEO of evoblade. “By developing and optimizing a retrofittable flow element, we wanted to achieve a technical and economic improvement in the properties of existing systems that leverages the advances in technical understanding.”

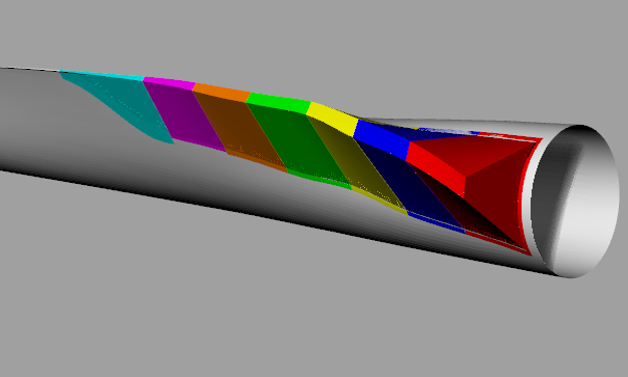

The EvoFlap can be adapted to different rotor blade types. The NEG Micon NM 82 turbine type with a rated output of 1.5 megawatts (MW) and a rotor blade length of 40 meters was selected as the basic system for the optimization. The add-on spoiler, composed of a composite glass fiber-reinforced polymer (GFRP) sandwich construction, has an overall length of 10 meters, which is divided into seven segments to allow assembly directly on an installed rotor blade.

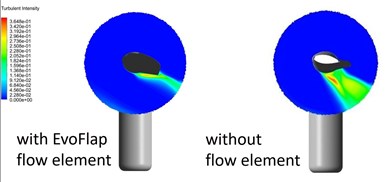

Sectional view of the rotor blade looking at the nacelle from above, showing the reduced turbulence intensity with EvoFlap. Photo Credit: Deutsche Windtechnik

“The blade does not have to be removed from the hub to allow EvoFlap to be installed, and this reduces the amount of work and costs,” Frank Kortenstedde emphasizes. “Also, the blade structure is not damaged by gluing the segments onto it, and the EvoFlap blends harmoniously with the blade design.” To validate the annual energy output, the company, ROMO Wind (Einsiedeln, Switzerland), was commissioned to carry out independent performance monitoring using iSpin spinner anemometer technology, which measures wind speed in front of the turbine for direct and undisturbed data. In addition to the test system, a second (adjacent) turbine of the same type was equipped with iSpin technology as a reference system.

The results of the side-by-side study, which ran from August 2015 to March 2019, confirmed the increase in annual energy production (AEP), which was predicted using simulated data. Recent results also show a 6% increase in AEP with an average annual wind speed of 7 meters per second. In addition to increasing the yield, it was demonstrated that the EvoFlap also increases the bending and torsion strength of the rotor blade, which improves overall service life of the blade.

“Depending on the useful life of the EvoFlap, a possible extension of 1.2 to 2.6 years beyond the maximum service life of 20 years can be achieved,” Frank Kortenstedde explains. “A very high level of technology transfer has been achieved. Retrofitting such large-scale flow elements is currently the absolute exception. Nevertheless, this research project shows significant potential positive effects.”

According to evoblade and partners, EvoFlap can theoretically be installed on all wind turbines that have a slender design in the blade root area. However, while the flow element is suitable as a retrofit solution, it needs to be adapted to the individual characteristics of the corresponding blade type.

“Even though retrofitting flow elements is not always an option, and the initial design and features of turbines are up to the system manufacturers, we are still very happy to participate in and support research projects like this that look at technologies of the future,” adds Matthias Brandt, director of Deutsche Windtechnik AG. “The results are moving in the right direction and are helping the entire industry!”

Related Content

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreJEC World 2022, Part 3: Emphasizing emerging markets, thermoplastics and carbon fiber

CW editor-in-chief Jeff Sloan identifies companies exhibiting at JEC World 2022 that are advancing both materials and technologies for the growing AAM, hydrogen, automotive and sustainability markets.

Read MoreComposites enable epic interior for Museum of the Future

For this one-of-a-kind lobby, AFI pioneered digital, reconfigurable molds to achieve organic-shaped, multifunctional panels and stairwell cladding.

Read MoreJEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

Read MoreRead Next

UMaine awarded $2.8 million to accelerate AM wind blade development

Additive manufacturing with bio-based, 100% recyclable feedstocks reinforced with wood can reduce construction time by six months and cut costs by 25-50%

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)