Velocity Composites completes first kits from advanced manufacturing facility in Alabama

Full-rate production for GKN Aerospace should begin before next financial year, site will serve as hub for other launch customers as composites grow in wind energy, urban air mobility and electric vehicles.

Read MoreDIAB commits to circular business model

Diab uses recycled raw materials to make core materials; Diab customers can use such products with recycled content to help lower their carbon footprint and Diab assists in reusing its products at end of life.

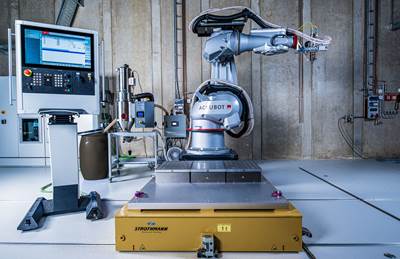

Read MoreAirborne, Accudyne partner to provide automated composites solutions worldwide

The two companies have signed an MOA to collaborate on further development of digital automation systems for composites manufacturing in aerospace, renewable energy, future mobility and more.

WatchAddyx carbon exoskeleton technology enables molded ribs inside hollow composite structures

Using a water-soluble mandrel, carbon exoskeleton opens paradigm for topology-optimized composites, cutting weight, manufacturing time and scrap rate.

WatchFACC reports growth due to short- and medium-haul aircraft, potential expansions

Citing a 22% increase in revenue, FACC plans to expand its workforce and Plant 6 in Croatia as it pursues continued growth in civil aviation, UAM and space sectors.

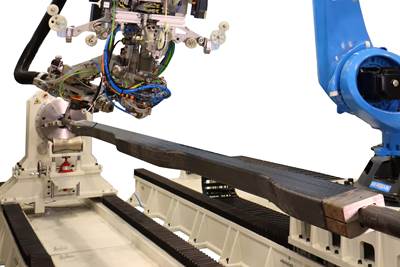

Read MoreSiemens Gamesa, Airborne develop automatic preforming robot system for offshore wind blades

Danish-funded ALMA project furthers collaboration, adds new functionality, advanced sensor systems and digital twinning for reduced man-hours, waste and cost per blade.

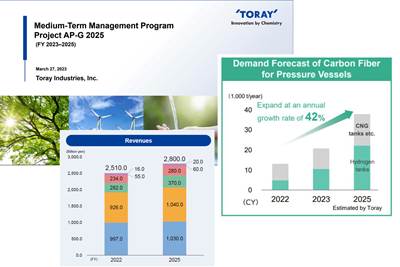

Read MoreToray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

WatchDemonstrating functionalized, cost-effective composites using additive extrusion

Hybrid thermoset/thermoplastic composite part with 3D-printed functionalization demonstrates technology possibilities and EmpowerAX open platform offering expertise from members throughout the process chain.

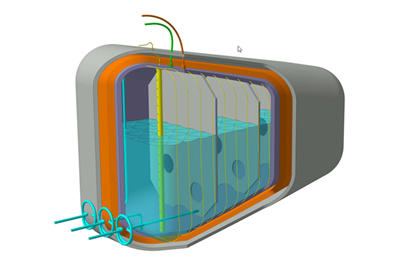

WatchCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

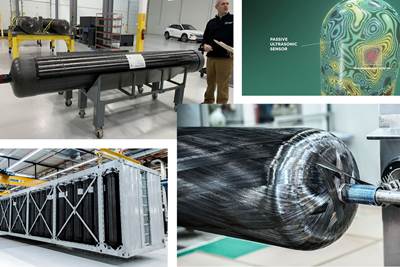

Read MoreHexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Watch