Vertically integrated CMC supply chain

GE Aviation's new ceramic matrix composite supply chain includes fiber, prepreg and unprecedented parts production facilities, plus a strongly tied 4-bump development stream.

With its full-rate CMC parts production facility in Asheville, NC already in operation (see CW’s “Plant Tour: GE Aviation, Asheville, NC”), GE Aviation (Evendale, OH, US) is investing more than US$200 million to construct adjacent silicon carbide (SiC) ceramic fiber and unidirectional ceramic-matrix composite (CMC) prepreg facilities on a 100-acre campus in Huntsville, AL, US. This is the most vertically integrated new material supply chain GE has ever constructed in the US (see Fig. 2 above). The ceramic fiber plant is supported by US$21.9 million in funding from the US Air Force Research Lab (AFRL, Dayton, OH, US) Title III Office, while the CMC tape operation is financed solely by GE.

The new SiC fiber plant will license fiber-producing technology from NGS Advanced Fibers Co. (Toyama, Japan), the only other large-scale SiC ceramic fiber factory in operation. Formed in 2012, NGS is a joint venture (JV) between Nippon Carbon Fiber (Tokyo, Japan), GE Aviation and Safran (Paris, France) and is in final qualification of its Japanese factory expansion to meet growing worldwide demand.

“NGS will continue forward,” says Michael Kauffman, GE Aviation’s general manager for composite and ceramics manufacturing. He explains that the new JV, Advanced Silicon Carbide Fiber, is indeed between the same companies as in NGS, but the percentages are different, GE owns 50%, and it is a US entity. The SiC fiber plant in Huntsville is seen as complementary, and will coordinate the sale of fiber with its NGS partners. Both businesses will continue to sell SiC fiber for GE and to all external customers. “Selling fiber externally is required per the AFRL Tile III funding,” says Kauffman.

The adjacent prepreg tape facility, however, will remain solely a GE Aviation operation. “The tape will be split into multiple widths as needed for nesting efficiency in the parts we make,” notes Kauffman. “This prepreg tape will support GE Aviation military and commercial products as well as components for GE power turbines.” The CMC prepreg facility will begin operations in the summer of 2018. The CMC fiber facility will follow in the spring of 2019. Once fully operational, the Huntsville facilities will employ up to 300 people.

As noted in CW’s Plant Tour article, at full capacity, the CMC prepreg and fiber facilities will produce 20,000 kg of material and 10,000 kg of SIC fiber per year, respectively. Each LEAP engine uses approximately 1 kg of CMC material. GE Aviation is also incorporating CMC components into advanced military engines including the advanced turboshaft demonstrator FATE (Future Affordable Turbine Engine) and the GE3000 for the US Army’s Improved Turbine Engine Program (ITEP) program, which aims to provide 50% more power, a 65% increase in power-to-weight, a 20% longer engine life and up to a 25% improvement in fuel consumption, as well as lower production and maintenance costs for the Black Hawk and Apache helicopter fleets.

The five CMC parts in the GE9X which will power the Boeing 777X will have a higher operating temperature than in the LEAP engine. “We’re in certification of these parts now,” says Kauffman. “We’ve shipped four sets already during the supply chain scale-up.” He adds that GE Asheville will stay the main industrial conversion site for CMC components, “until we have enough products to outgrow this facility.”

4-bump development stream

Kauffman explains that ongoing R&D is a key part of the this CMC supply chain (see top “circle” in Fig. 2). “It’s what we call our 4-bump development stream,” he says. “We have a tight linkage between GRC through to Asheville, which means a tight-knit value stream. For example, we track product yields collectively as a supply chain. If we need to work an issue, we send a hypothesis upstream, they work it out, test it and send back amended specifications, standard operating procedures, etc.” He notes that each unit can problem-solve and solutions can then be trialed in low-rate production at the Newark CMC lab. “For example, this could be for fine-tuning thermal cycles or understanding variation in properties,” says Kauffman. “We don’t experiment in our parts production line. We experiment in our labs, prove out in our LRIP center and then we bring it in to our high-rate production facilities.”

At the same time, Kauffman stresses, this R&D development stream enables a completely new approach to structural design. “These are disruptive design concepts,” he reports, “which are being vetted and tested. We will mature these and push toward industrialization. Thus, we have a push and pull advancement in CMC technology.”

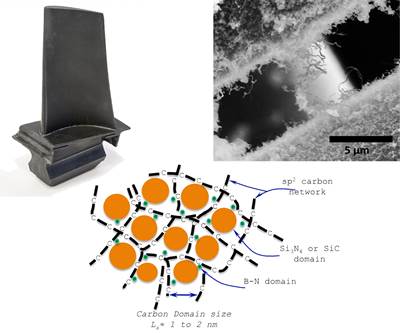

There are also improvements being sought. “We’re working on advancing the temperature capability of the SIC/SIC system in support of military applications, Kauffman said. This requires a different SiC/SiC microstructure, higher temperature environmental barrier coating (EBC) and potentially a higher temperature fiber. We have a roadmap to achieve this.”

Read more about research into future CMC materials in the CW Blog, titled "The next generation of ceramic matrix composites."

Related Content

AMRC fiber handling expertise aids CMC coating technology

The CICSiC project successfully developed equipment and processing know-how associated with the uniform, continuous coating of SiC-based CMC, to bring down cost, and improve performance and reliability for new designs, applications.

Read MoreGE Aerospace awarded demonstration contract for NASA HyTEC project

Turbofan engine small core technology development with CMC-coated components targets enhanced fuel efficiency in single-aisle aircraft by mid-2030s.

Read MoreThe future of quartz and oxide fibers at Saint-Gobain Advanced Ceramic Composites

New business builds on 100-year legacy in quartz, prepares for growth, while starting production of oxide fibers to meet increased demand for CMC by aerospace and industrial sectors.

Read MoreBio-based SiC ceramics from wood polymer composites

Austrian research institute Wood K plus makes 95% silicon carbide ceramics more sustainable (>85% bio/recycled content), enables 3D shapes via extrusion, injection molding and 3D printing.

Read MoreRead Next

Commercialization of CMCs and developments for next-gen performance

As industrial production of parts begins, new developments offer promise for higher-temperature and more damage-tolerant ceramic matrix composite (CMCs).

Read MorePlant Tour: GE Aviation, Asheville, NC, US

An avant-garde approach to unprecedented CMC parts production.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More