The evolution of infusion

As resin infusion continues to infiltrate composites, fabricators across the market spectrum drive materials and process developments in pursuit of process control.

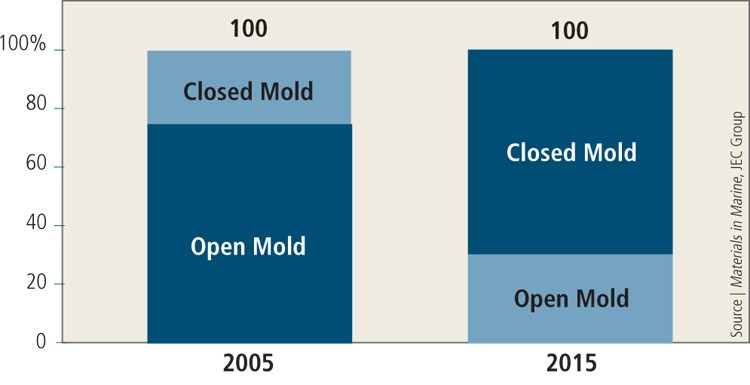

The use of the resin infusion process has grown significantly in the 25 years since fiberglass boatbuilder/composite materials distributor Seemann Composites (Gulfport, Miss.) introduced SCRIMP (Seemann Composites Resin Infusion Molding Process). Closed molding in boat decks, for example, grew from 5 percent in 2000 to between 20 and 50 percent by 2005, according to Materials in Marine, a study published by JEC Group (Paris, France) in 2006. The same study predicted that by 2015, closed molding would be used for more than 60 percent of marine composites (see Fig. 1). The process has evolved with equal vigor, as evidenced by the many other acronyms and patents that followed SCRIMP since 1987 (see "Profusion of Infusion"). Early on, each new development was aimed primarily at improving laminate quality: increased fiber content, decreased voids and better surface finish. But more recently, process refinements include a push for faster infusion by formulating resins to lower viscosities and infusing at elevated temperatures to speed cure. Infusion also moved from hulls to more complex deck structures, and now to larger, thicker structures with integrated stiffeners, which require resins with longer working time and less exotherm. Today, the emphasis in infusion innovation is trending to process control. A number of the newer techniques and equipment systems are aimed, therefore, at reducing process risk and increasing quality and repeatability for novice users.

Evolutionary landscape

Although resin infusion’s technical superiority to “bucket and brush” layup is beyond question, its adoption by molders of every stripe is driven just as strongly by concern for worker welfare. “In Europe, manufacturers of marine and industrial composites will have to look at infusion and other closed molding processes, due to the increased regulation of styrene,” observes infusion researcher John Summerscales, an associate professor of composites engineering at the University of Plymouth (Plymouth, U.K.). Currently, styrene exposure limits vary by country in Europe, from 20 to 100 parts per million (ppm), with the U.K. maintaining the latter. However, in 2011, the European Chemical Industry Council (CEFIC) proposed that the derived no-effect level (DNEL) for worker inhalation exposure to styrene should be 20 ppm (over an eight-hour, time-weighted average) and that this DNEL might be used to harmonize styrene exposure limits across the European Union.

The American Composites Manufacturers Assn. (ACMA) has responded to similar pressure in the U.S. by proposing an occupational exposure limit (OEL) of 50 ppm, which it says will mean “working toward a target eight-hour average exposure of approximately 35 ppm.”

Resin infusion is an extremely effective way to meet these new limits. For example, during a 2009 National Institute for Occupational Safety and Health (NIOSH) walk-through survey of the LM Glasfiber (now LM Wind Power) wind blade facility in Grand Forks, N.D., the lowest personal breathing zone measurements for styrene were among the 21 workers performing infusion, all at less than 5 ppm.

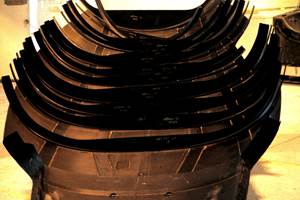

Indeed, wind blade manufacturers migrated to resin infusion and other closed mold processes between 2000 and 2005 (see Fig. 2), with production of large blades (length >30m/98 ft) reportedly now split between infusion (65 percent) and prepreg (35 percent). Some industry pundits predicted that the use of prepreg would increase with the quest for automation through automated tape laying (ATL) machines. However, ATL has been limited to spars so far, and industry experts like Steve TPI Composites Inc. Nolet, TPI Composites’ (Scottsdale, Ariz.) principal engineer/director of innovation, doubt its ability to match manual placement rates of 1,500 kg/hr (3,307 lb/hr) and targeted finished product costs of $5/lb to $10/lb.

Meanwhile, the growth of infusion in aerospace composites continues as manufacturers pursue freedom from the cost, size limits and workflow bottlenecks of autoclaves (see “Learn More”). However, their standards are demanding, and include fiber content greater than 50 percent by volume (not weight) and less than 2 percent void content. Driven by the need for higher service temperatures, infusion at this end of the composites spectrum is venturing beyond epoxies into bismaleimides (BMIs; cure at 350°F to 500°F/177°C to 260°C) and polyimides, such as NASA’s new phenylethynyl terminated imide (PETI) resins (cure at 630°F to 700°F/332°C to 371°C).

To this end, NASA developed a high-temperature vacuum-assisted resin transfer molding process (HT-VARTM) adapted from Controlled Atmospheric Pressure Resin Infusion (CAPRI, patented by The Boeing Co., Chicago Ill.). CAPRI is a variation of SCRIMP that employs vacuum debulking and a reduced pressure differential to minimize thickness gradients and resin bleeding. In HT-VARTM, the resin and fiber reinforcements are heated to facilitate flow and wetout. Aluminum screen is used as a flow medium because it stands up well to heat. A second bag provides redundancy in case of leaks during infusion. (See “SIDEBAR”).

Bionic infusion

Wind blade manufacturers continue to be the major force driving resin infusion innovation. LM Wind Power’s reported four-hour infusion of its P73.5 turbine blade’s glass fiber-reinforced, balsa-cored shell was a newsworthy milestone. The infusion process, which was extraordinarily brief for the world’s longest turbine blade, owed its speed to a specially formulated polyester resin. Indeed, almost every resin supplier now has a low-viscosity product for infusion (see “Infusion Resin Chart”). Joining the low-viscosity polyesters and epoxies common in wind blade infusion is a new one that aspires to reset the game: Bayer MaterialScience AG’s (Pittsburgh, Pa.) new Baydur polyurethane (PU) resin for wind blades. The company claims it infuses twice as fast as epoxy, yet it achieves equivalent static properties. Moreover, the material is made from a sustainable soy-based polyether polyol and is being marketed as an alternative to traditional infusion resins, offering long gel times with a faster demold time than epoxy.

The latter sounds much like the snap-cure capability of the VITROX PU resins introduced in 2008-2009 by Huntsman Polyurethanes (Auburn Hills, Mich., and Everberg, Belgium). Citing tunable characteristics — such as room temperature viscosity from 150 to 2,000 cps, Tg up to 250°C/482°F, delayed onset of cure and a long pot life — Huntsman initially marketed VITROX for resin infusion, filament winding and resin transfer molding (RTM). Yet recent product and merger announcements suggest this PU formulation might have found commercial success in RTM of automotive parts and cured-in-place pipe (CIPP) liners.

Meanwhile, Bayer says its Baydur PU for infusion can reduce wall thicknesses for lightweighting without sacrificing strength. It has been demonstrated in a wind blade root ring, infusing 63 layers of Vectorply Corporation (Phenix City, Ala.) biaxial glass fabric and a 4-ft by 1.5-ft (1.2m by 0.5m) heavy truck airfoil. Bayer says the testing showed that its PU root ring has three times greater fracture toughness vs. a comparable epoxy blade root ring, along with a ten-fold improvement in fatigue tensile strength and better fatigue crack resistance. The truck part achieved a Class A surface finish with an in-mold polyurethane gel coat.

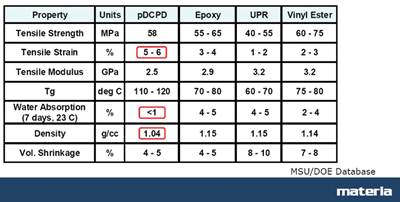

Also aimed at infusion of wind turbine blades, Materia Inc.’s (Pasadena, Calif.) new Proxima polydicyclopentadiene (pDCPD) resin takes viscosity to a new low. Featuring Nobel Prize-winning olefin metathesis catalyst technology (see the sidebar titled “Backgrounder: Proxima pDCPD,” below or click on its title under "Editor's Picks," at top right), it has a reported viscosity of 10 to 20 cps (at 23°C/73°F). Materia claims it enables one-shot infusion of thick sections (e.g., blade root areas), reduced void content and higher fiber volume fractions of 58 to 60 percent. (It also is recommended as a solution for complete wetout during infusion of traditionally problematic carbon fiber laminates.) Infusion rates are up to 10 times faster than standard infusion resins, and cured parts weigh less but have greater fracture toughness and fatigue resistance.

Proxima may have some competition. In July 2011, inventors Maurice Marks and Gary Hunter, both chemists for Dow Chemical Co. (Midland, Mich.) in Lake Jackson, Texas, received U.S. patent 2011/0163474, which claims a novel epoxy resin formulation for use in vacuum infusion that uses a divinylarene dioxide, such as divinylbenzene dioxide (DVBDO), to achieve viscosity as low as 10 to 25 cps at 25°C/77°F, a two- to four-hour gel time, cure temperatures from 15°C to 200°C (59°F to 392°F) and a Tg of 60°C to 170°C (140°F to 338°F).

According to the patent, DVBDO is pursued as an alternative to low-viscosity epoxy resin for infusion because the typical procedure of adding a reactive diluent also reduces the heat resistance of the cured composite. To achieve the heat-deflection temperature (HDT) required by leading wind turbine certification body Germanischer Lloyd (GL, Hamburg, Germany), many formulators add cycloaliphatic amine curing agents. Dow’s patent states that this is costly and only partially effective.

If they were offered in a commercial product at a slightly lower cost than current amine-based epoxy infusion resins, the range of properties claimed in the DVBDO patent would place the Dow product head to head with Materia’s Proxima pDCPD resin. However, at CT press time, neither company had set a date when its technology will be available to the market.

Managing the process

Although resins with extremely low viscosities are improving wetout and reducing mold fill time, they also can place greater demands on molders for vacuum integrity and process control. Indeed, another branch of infusion’s evolutionary tree is focused on process management. “So much of the effort in infusion now is to speed it up,” says Ian Kopp, manager of TCM Composites, a new division of Kenway Corp. (Augusta, Maine). “But we have found that fast is not always better. For us, control is the key to infusion.”

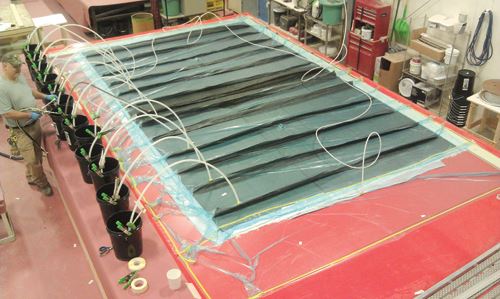

For Kenway, that key is Temperature Controlled Molding (TCM), a heat-activated cure and infusion control technology, developed when the company began infusing 5- to 7-inch (127- to 178-mm) thick industrial structures in one shot, using vinyl ester resin (see photo, p. 24). Before TCM, the results were hit and miss, with periodic exotherm spikes that exceeded 500°F/260°C. To deal with the spikes, Kenway enlisted the expertise of infusion consultant André Cocquyt (GRPguru.com, Brunswick, Maine) and resin supplier CCP Composites (N. Kansas City, Mo.). Together, they developed the TCM system and then opened the new namesake division to exploit Arkema Inc.’s (King of Prussia, Pa.) BlocBuilder heat-activated catalyst technology, which is designed to delay onset of cure.

“Now you have the ability to infuse very thick laminates,” explains Kopp, “because the catalyst and resin can be mixed for long periods without initiation of cure.” However, controlled heating in the mold became a necessity, and cooling was just as vital to control exotherm. Kenway’s own proprietary technology enables even heating and cooling across the tool surface without the hot spots that are common with conventional electrical wiring or copper tubing (see the sidebar titled “Temperature control heats up,” below, or click on its title under "Editor's Picks").

“For us, there have been a lot of cost benefits to using TCM,” says Kopp. He illustrates this point by describing a U.S. Navy project that involved large panels with 2-inch/51-mm thick cores. “Because of the insulative effect of the core, it would be difficult to maintain a constant temperature and flow front through the part, but TCM tools make the infusion very easy to control.” This project also used three 100-oz/yd2 (3,391g/m2) fabrics, all made to the same specification, but each affected processing differently.

Seasonal temperature changes alone can cause problems with infusion. “Previously, infusions like this were not repeatable in a timely fashion,” Kopp explains, “However, by heating the resin, mold and dry stack materials, we are keeping everything at a constant temperature, which enables us to achieve the same processing characteristics and infusion times on a repeatable basis. Thus, we are able to control our laminate quality and produce very consistent parts.”

Other benefits include greater fiber content — as much as 70 percent by volume — and improved cosmetics. Moreover, these results can be achieved with polyester, vinyl ester, epoxy and, most recently, phenolic resins. Currently, Kopp and team are infusing light rail and other transportation structures with phenolics to meet flammability and smoke regulations. He acknowledges, “Without TCM we wouldn’t be in this market at all.” To date, the company has manufactured molds good to 200°F/93°C, and distributor Composites One (Arlington Heights, Ill.) now includes the TCM process in its Closed Mold Alliance composites trade show demonstrations. But even better performance is on the way. In TCM’s work with the University of Maine to investigate thermoplastic composite wind blades, it is exploring capabilities up to 400°F/204°C.

Control is the goal

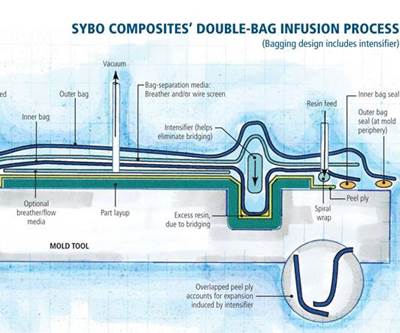

The double-bag infusion technique has incited much debate since its coverage in CT, with multipage threads on both CompositesCentral.com and LinkedIn’s Composites Industry Forum (see links to threads at end of article). Those who use the technique claim it helps them achieve consistently higher fiber content and lighter weight laminates. Naysayers decry the alleged physics and claim improved results are merely a result of improved infusion procedures. Process developer Russ Emanis (Dexell Composites, Keller, Texas) describes double-bag infusion as merely one means of process control for those new to infusion. “I understand there are experts who doubt the technique,” he says. “My goal isn’t to become an ‘industry expert,’ but simply to help companies use infusion to produce lighter weight, stronger parts more consistently and with less risk.” Emanis says double-bag infusion does not fit every part or fabricator, but he sees value in it, even if it merely increases the number of companies that can access infusion and use it with confidence.

His advocacy of double bagging aside, Emanis recognizes that infusion process control needs to be more automated. Toward that end, he has worked with SYBO Composites (St. Augustine, Fla.) and Vectorworks (Titusville, Fla.) to develop Aero-Fusion, an automated system that not only controls vacuum but delivers precisely mixed epoxy resin and hardener at a controlled rate during infusion, eliminating pails of mixed resin and mix ratio errors. The mobile unit reportedly will cost about half the price of existing equipment in a significantly smaller footprint.

The first step toward Aero-Fusion was Emanis’ development of the Accu-Fusion delivery head, which mixes epoxy resin and hardener at the point of infusion so the feed line becomes the hot pot, eliminating wasted resin. Emanis explains, “Often, multiple 5-gal [19-liter] pails of resin will be mixed at one time to service a medium-sized infusion. Because of the reaction chemistry and limited pot life, gallons of resin end up being thrown away.”

The Accu-Fusion delivery head has one feed line placed in the resin reservoir and another in the hardener. These components are drawn separately into the head via vacuum, then mixed and delivered into the part at low pressure. Emanis estimates that this alone saves as much as 30 percent of infusion labor costs, because mixing time is eliminated and no personnel are required to stand idle while waiting to blend and pour. This system also eliminates the risk of mix-ratio error, which can prevent the epoxy from curing properly or reaching its full strength, as well as the risk of runaway exotherm from mixing too much epoxy at once. The Accu-Fusion head is designed to deliver the amount of resin required by the infusion at the right time. Codeveloper and SYBO CEO Dana Greenwood says that when his company infuses an 18-ft/5.5m hull for customer Chittum Skiffs (St. Augustine, Fla.), “we have, at most, 12 oz [340g] of [mixed]resin outside of the bag.”

Vectorworks CEO Jeff Gray notes that the method would have been ideal when his company infused 18 large parts for the Swift megayacht’s 325-ft/99m long superstructure (read more about this project in “From frigate to luxury gigayacht,” under "Editor's Picks"). “If we had the Aero-Fusion system in place, we could have not only eliminated the bucket mixing, we could have used the material lines again for each subsequent part since no catalyzed materials run through the feed lines up to the Accu-Fusion head.”

Greenwood got involved during the second stage of development: the Pro-Fusion pump. Emanis recalls, “At first, I had a vacuum-only system, which worked fine for small parts, but we couldn’t maintain the level of accurate mixing required for infusing large parts.” Emanis and Greenwood worked together to develop a system that could handle high-viscosity epoxy resin while mixing in low-viscosity hardeners and still maintain accurate ratios from 1:1 to 6:1.

“This is the challenge,” says Emanis, noting, for example, that CPD 2110/9260 room-temperature infusion epoxy (Endurance Technologies, Minneapolis, Minn.) uses a 1200-cps resin and a 30-cps hardener to produce a mixed resin with a viscosity of 300 cps. “Epoxy infusion resins can be very sensitive to mix ratios,” Emanis notes. “For example, ±3 percent deviation per component is unacceptable for many of these systems. Aero-Fusion is designed to get the margin of error down to as close to zero as possible.”

Greenwood adds, “I have an RTM gun, which cost $26,000 and was designed specifically for modified infusion and RTM light, but it can’t handle resins with viscosity greater than 1,000 cps. The Aero-Fusion system easily handles materials in excess of 5,000 cps, but we had to develop unique technology to enable this.”

“A lot of shops will infuse using an RTM gun,” Emanis points out. “However, frequently the vacuum bag gets overinflated, so they will turn the pump off and let the vacuum pull the resin into the part. This can be made to work, but it can also fail if not correctly controlled. With our system, you are balancing the flow of resin into the part with the flow front inside, preventing the part from being overloaded.”

Aero-Fusion prototype systems were field tested in 2011 and then refined. Designs for the second-generation are out to manufacturers for quotes and should be available later in 2012. And Emanis is working with a variety of companies to refine the Aero-Fusion system.

Currently, the Aero-Fusion system can infuse multiple parts in series. However, Emanis will be testing its capability to run parts simultaneously, using a manifold. Greenwood explains, “For large infusions, the ideal would be to have a manifold on the resin and hardener reservoirs and then run lines to multiple Accu-Fusion heads, one at every point where a resin feed is required, so that there is no volume of mixed resin pooled in the lines.” They also see the eventual development of a system for unpromoted vinyl esters, promoting at the head as the resin is introduced into the part. The system is expected to offer the same drop in cost vs. currently available vinyl ester dispensing systems while eliminating surging.

To follow online discussions of Russ Emanis' double-bag infusion technique, click on the followign links:

http://www.linkedin.com/groupItem?trk=eml-anet_dig-b_pd-ttl-cn&gid=124555&view=&ut=11T7YHh7XAjRc1&srchtype=discussedNews&item=106993993&type=member

http://www.compositescentral.com/showthread.php?t=7075&page=3

Related Content

Understanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read MoreDoing the twist: A look at dimensional issues in high-temperature cured laminates

When it’s not the tooling, the root cause of dimensionally inaccurate composite parts often boils down to two things: fiber form(s) used and laminate symmetry.

Read MoreJEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

Read MoreDemonstrating functionalized, cost-effective composites using additive extrusion

Hybrid thermoset/thermoplastic composite part with 3D-printed functionalization demonstrates technology possibilities and EmpowerAX open platform offering expertise from members throughout the process chain.

Read MoreRead Next

Double-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

Read MoreBackgrounder: Proxima pDCPD

Materia Inc.'s (Pasadena, Calif.) Proxima, a completely new type of polydicyclopentadiene (pDCPD) thermoset resin, is said to offer the same mechanical properties as, and better long-term durability than, epoxy

Read More