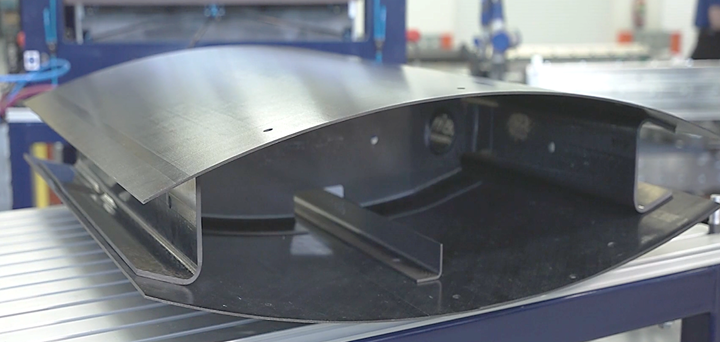

KVE INDUCT: Welding a torsion box demonstrator

To meet sustainability targets and market demands, the aerospace industry is searching for alternative joining methods. Automated assembly of thermoplastic composite structures by induction welding offers a solution. (Sponsored)

UD-tape based thermoplastic composites hold a great potential for both meeting sustainability targets and market demands. They allow for fully automated production of parts and can subsequently be joined without the traditional fasteners or adhesive bonding by applying welding technologies.

The induction welding process KVE INDUCT from KVE Composites is a well-established automated assembly process for carbon fabric-based thermoplastic, but welding of UD-tape based thermoplastic still offered some challenges until recently. KVE and Daher Aerospace are working to bring the technology to TRL 6 for UDs. In this digital demo, KVE showcases the technology and explains process fundamentals by welding a torsion box demonstrator.

For more information, please follow KVE on LinkedIn or visit their website.

Related Content

-

Digital Demo: Secure Vacuum Bag Seal Eliminates Single-Use Sealant Tapes in Closed Mold Process

Magnum Venus Products (MVP) has developed a reusable two-part seal for the vacuum infusion closed mold process, replacing single-use sealant tapes. (Sponsored)

-

Digital Demo: UV-Cured Powder Coating on Carbon Fiber

Keyland Polymer's R&D chemist will demonstrate the UV powder coating application process followed by UV curing on a carbon fiber water bottle holder. (Sponsored)

-

Digital Demo: The Advantages of Thermoplastics Technology

From stronger, longer-lasting parts to creating sustainable options for composite parts, this demo will pique your interest in this emerging technology. (Sponsored)